High-boron stainless steel neutron-absorbing material and preparation method thereof

An absorbing material, stainless steel technology, applied in shielding, nuclear engineering, reactors, etc., can solve the problem of difficult to avoid the continuous network eutectic boride of the grain group, and achieve good r-ray and neutron absorption performance, material consistency. High density, high relative density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The composition of the high-boron stainless steel neutron absorption material provided in this embodiment is. B: 2.1%, Cr: 19%, Ni: 14%, C: 0.08%, Mn: 2%, Si: 0.75, P≤0.045%, S≤0.030 and the rest is iron. These elements are added in the form of iron alloy.

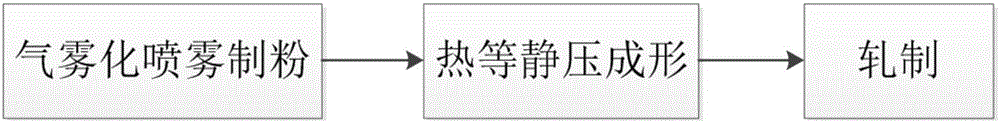

[0033] Such as figure 1 As shown, the preparation of the high-boron stainless steel neutron absorbing material in this embodiment sequentially includes the following steps:

[0034] (1) The raw material powder preparation steps: gas atomization melting various ferroalloy components, 100°C higher than the melting point, powder spraying pressure of 30MPa, the collected powder passes a 200-mesh sieve, and the yield of -200-mesh powder exceeds 50%;

[0035] (2) Hot isostatic pressing step: put the mixed powder into a sheath, vacuum exhaust temperature is 450℃, sealed, hot isostatic pressing treatment, pressing pressure is 100MPa, temperature is 950℃, and holding time is 1.5 hours, get hot isostatic pressing blank;

[0036] (3)...

Embodiment 2

[0039] The composition of the high-boron stainless steel neutron absorbing material provided by this embodiment is B: 0.25%, Cr: 15%, Ni: 12%, C: 0.20%, Mn: 1.5%, Si: 2.5%, P≤0.045%, S ≤0.030 The rest is iron. These elements are added in the form of iron alloy.

[0040] The preparation of the high-boron stainless steel neutron absorbing material in this embodiment sequentially includes the following steps:

[0041] (1) Preparation steps of raw material powder: gas atomization melting various ferroalloy components, 150°C higher than the melting point, powder spraying pressure of 25MPa, the collected powder passes through a 150 mesh sieve, and the yield of -150 mesh powder exceeds 50%;

[0042] (2) Hot isostatic pressing step: put the mixed powder into a sheath, vacuum exhaust temperature is 350℃, sealed, hot isostatic pressing treatment, pressing pressure is 120MPa, temperature is 1050℃, holding time is 2.0 hours, get hot isostatic pressing blank;

[0043] (3) Hot rolling step: hot-r...

Embodiment 3

[0046] The composition of the high-boron stainless steel neutron absorbing material provided by this embodiment is B: 0.6%, Cr: 15%, Ni: 12%, C: 0.20%, Mn: 1.5%, Si: 2.5%, P≤0.045%, S ≤0.030 The rest is iron. These elements are added in the form of iron alloy.

[0047] The preparation of the high-boron stainless steel neutron absorbing material in this embodiment sequentially includes the following steps:

[0048] (1) Preparation steps of raw material powder: gas atomization melting various ferroalloy components, 200℃ higher than the melting point, powder spraying pressure of 20MPa, the collected powder passes a 100 mesh sieve, and the yield of -100 mesh powder exceeds 55%;

[0049] (2) Hot isostatic pressing forming step: Put the mixed powder into a jacket, vacuum exhaust temperature at 300℃, sealing, hot isostatic pressing treatment, pressing pressure is 140MPa, temperature is 1100℃, and holding time is 2.5 hours, get hot isostatic pressing blank;

[0050] (3) Hot rolling step: ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com