FRP pipe and thick-wall steel pipe compounding hollow recycled concrete pile

A technology of recycled concrete and thick-walled steel pipes, which is applied to sheet pile walls, buildings, and infrastructure projects, can solve the problems of consuming steel molds or wood molds, increasing workload and construction costs, and preventing pile body from deteriorating and reducing The effect of large pile size and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

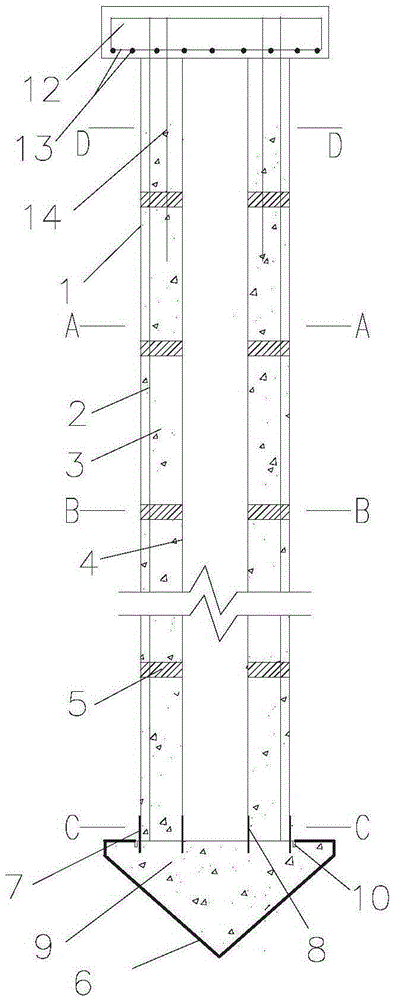

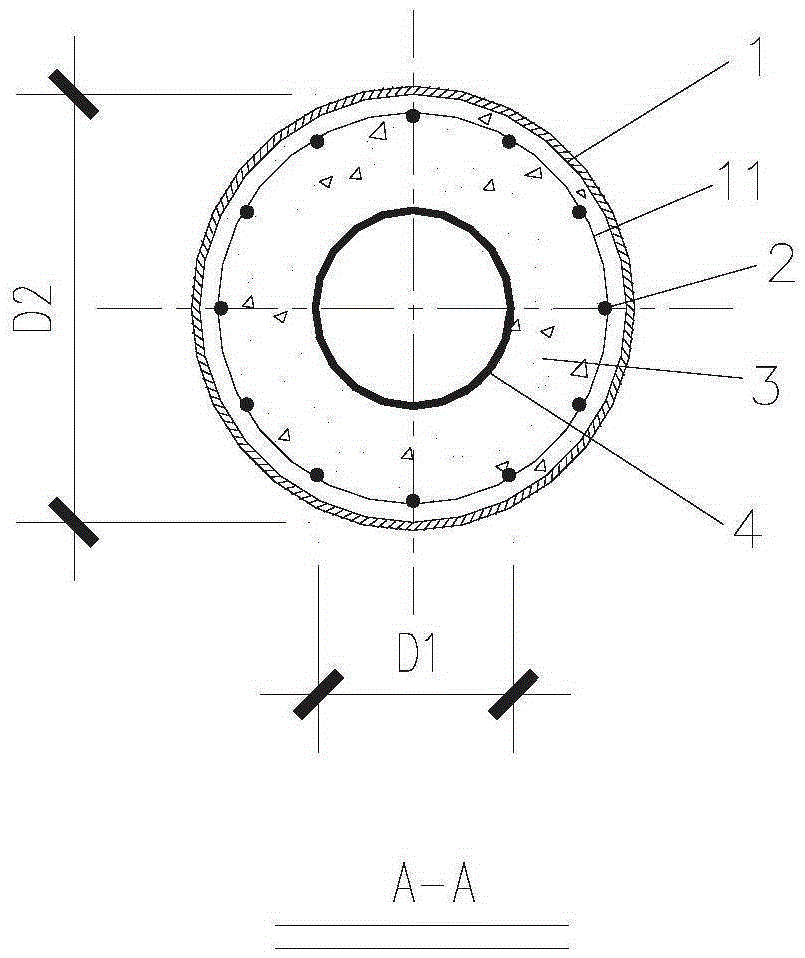

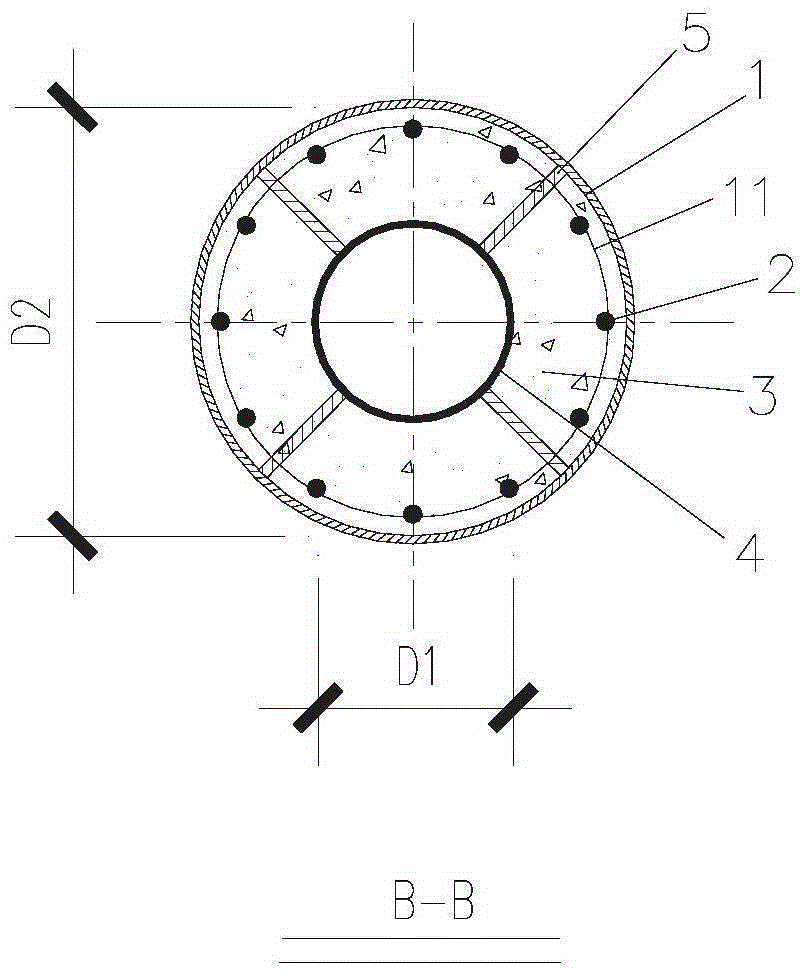

[0033] Such as Figures 1 to 6 As shown, the composite hollow recycled concrete pile of FRP pipe and thick-walled steel pipe of the present invention (the outer diameter is 500mm, and the pile length is 25m) is mainly made of FRP pipe 1, circular steel cage skeleton, thick-walled steel pipe 4 and recycled concrete 3 ; The circular steel cage skeleton and the thick-walled steel pipe are placed in the FRP pipe, and the three are arranged concentrically; recycled concrete is poured in the annular space between the FRP pipe and the thick-walled steel pipe. in,

[0034] The length of the FRP pipe is 30cm-35cm greater than the design depth of the pile body, the outer diameter of the FRP is 500mm, and the wall thickness of the pipe is 5mm.

[0035] The circular reinforcement cage skeleton is welded by longitudinal reinforcement 2 (type 8C20) and spiral stirrup 11, and the longitudinal reinforcement is evenly arranged along the circumference of the FRP pipe. The spiral stirrup in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com