Method for producing fine powder and the fine powder produced by the same

a technology of fine powder and fine powder, which is applied in the direction of grain treatment, biocide, pharmaceutical product form change, etc., can solve the problems of contaminating difficult to make into a pharmaceutical product in some cases, and affecting the quality of the raw material to be pulverized, etc., to achieve easy water-solvable materials, pulverize low melting point materials, and uniform pulverization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

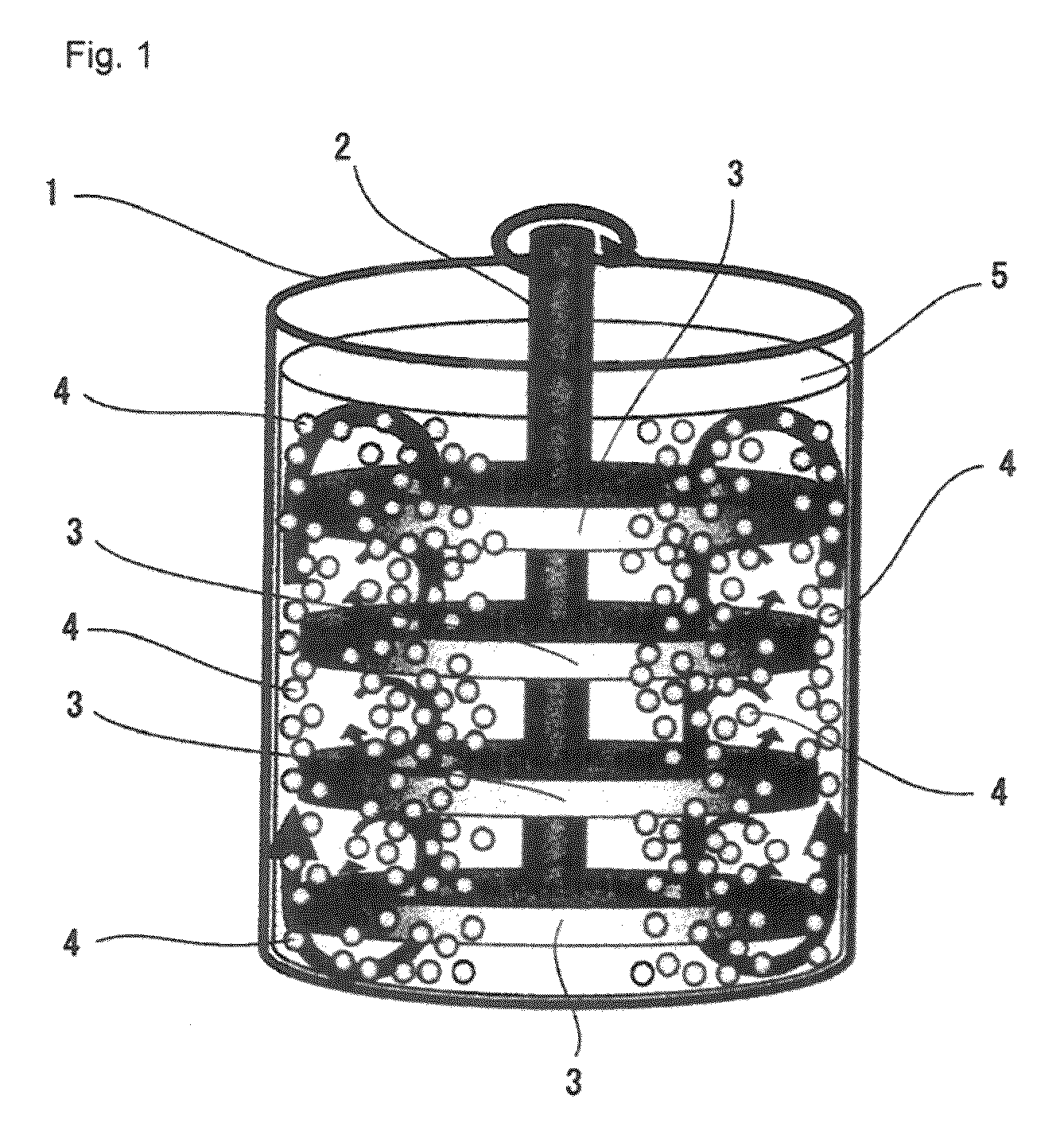

Image

Examples

example 1

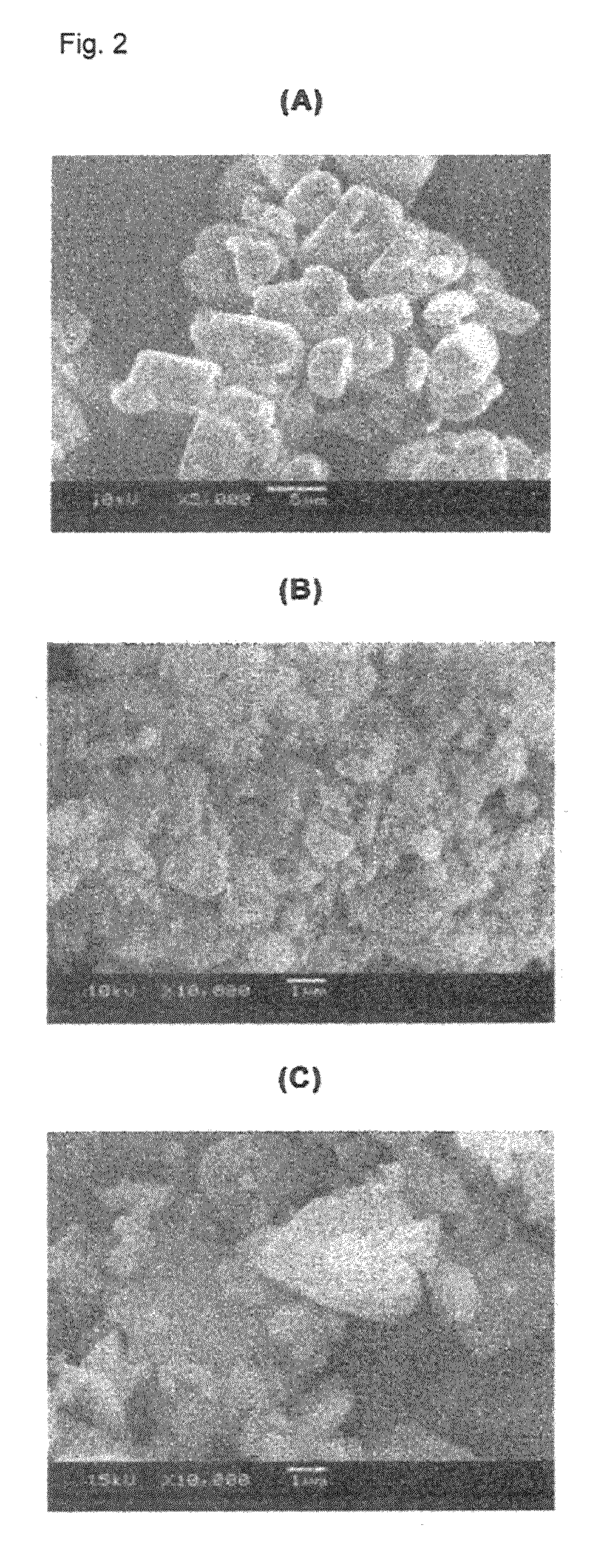

[0111]FIG. 2 shows electron micrographs (SEM) of the original bulk of phenytoin and the pulverized particles of phenytoin. Comparing FIG. 2(B) and FIG. 2(C), it was found that the particles pulverized by the LN2 bead mill were regular in shape and they are smaller in particle size and elongation than the particles pulverized by the Jet mill. Since the majority of the particles of phenytoin, which were pulverized by the LN2 bead mill, have the dimension of 1 μm or below, as shown in FIG. 2(B), it is found that the objective of pulverizing the material into submicron size has been attained by the ultra low temperature medium grinding with the LN2 bead mill, although it could not be attained by the conventional dry method for pulverization.

[0112]FIG. 29 shows a dry method particle size distribution that represents the effects of the rotating speed of the rotating shaft 2 on the particle size of pulverized phenytoin, while FIG. 30 shows a wet method particle size distribution that repre...

example 2

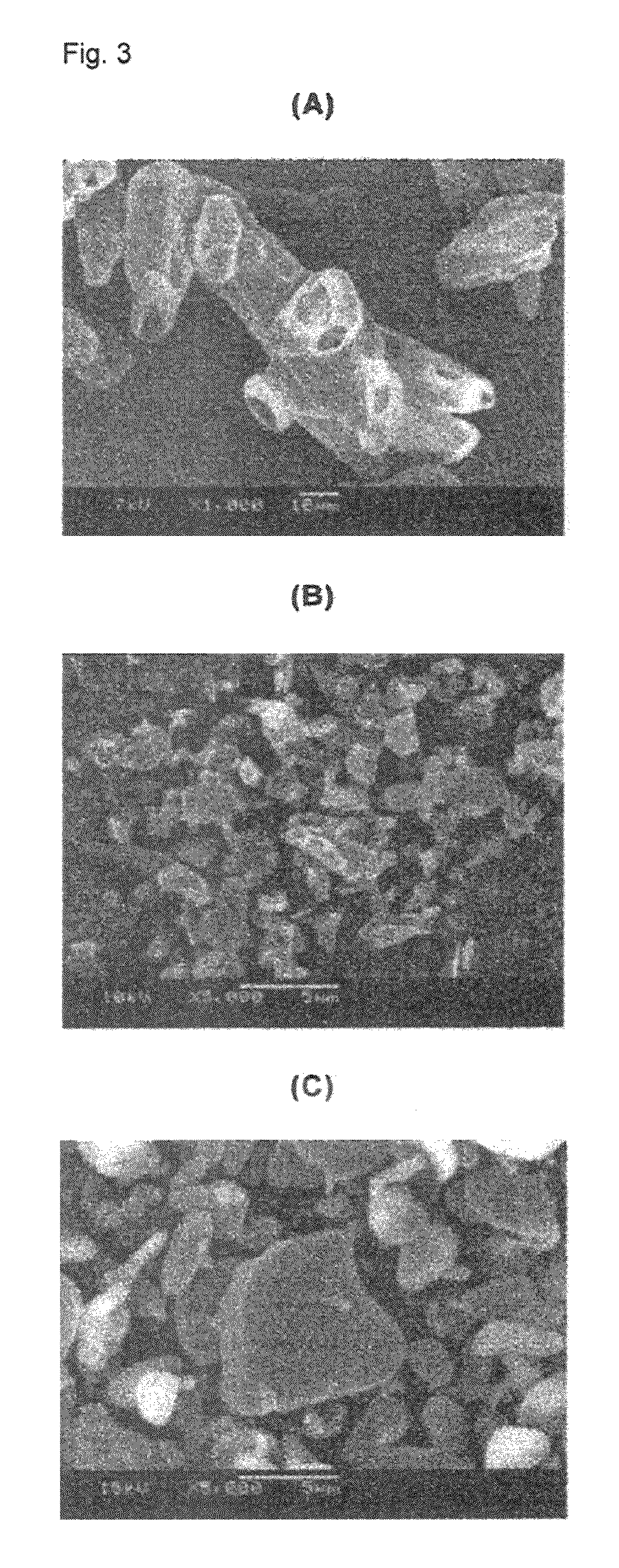

[0116]FIG. 3 shows electron micrographs (SEM) of the original bulk of ibuprofen and the pulverized particles of ibuprofen. Comparing FIG. 3(B) with FIG. 3(C), it was found that the particles pulverized by the LN2 bead mill were regular in shape and they are smaller in particle size and elongation than the particles pulverized by the Jet mill. It should be noted that the pulverization of low melting point material such as ibuprofen (76° C.) could be improved because the attack of heat generated at the time of pulverization could be modified immediately according to the present invention.

example 3

[0117]FIG. 4 shows electron micrographs (SEM) of the original bulk of salbutamol sulfate and the pulverized particles of salbutamol sulfate. Comparing FIG. 4(B) with FIG. 4(C), it was found that the particles pulverized by the LN2 bead mill were regular in shape and they are smaller in particle size and elongation than the particles pulverized by the Jet mill. It is also found that the method of the present invention is effective for the pulverization of water-soluble medicines such as salbutamol sulfate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameters | aaaaa | aaaaa |

| particle diameters | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com