A carbon-carbon composite material high temperature continuous heating furnace

A carbon-carbon composite material and composite material technology, which is applied in lighting and heating equipment, heating/cooling fabrics, furnaces, etc., can solve the problems of heating equipment sealing and heat preservation, insufficient heating continuity, and difficulty in continuous high-temperature heating treatment. Guarantee the continuous high temperature heating requirements, ensure the protection of the workpiece atmosphere, and avoid the effect of oxidation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

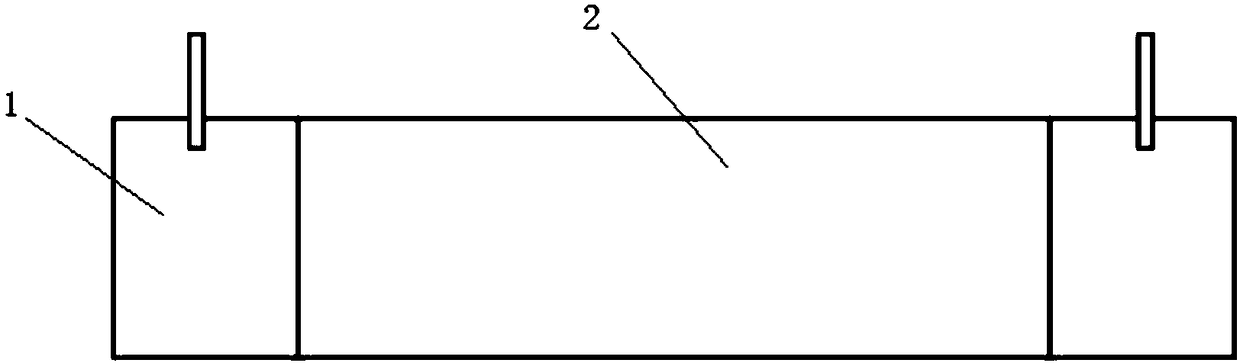

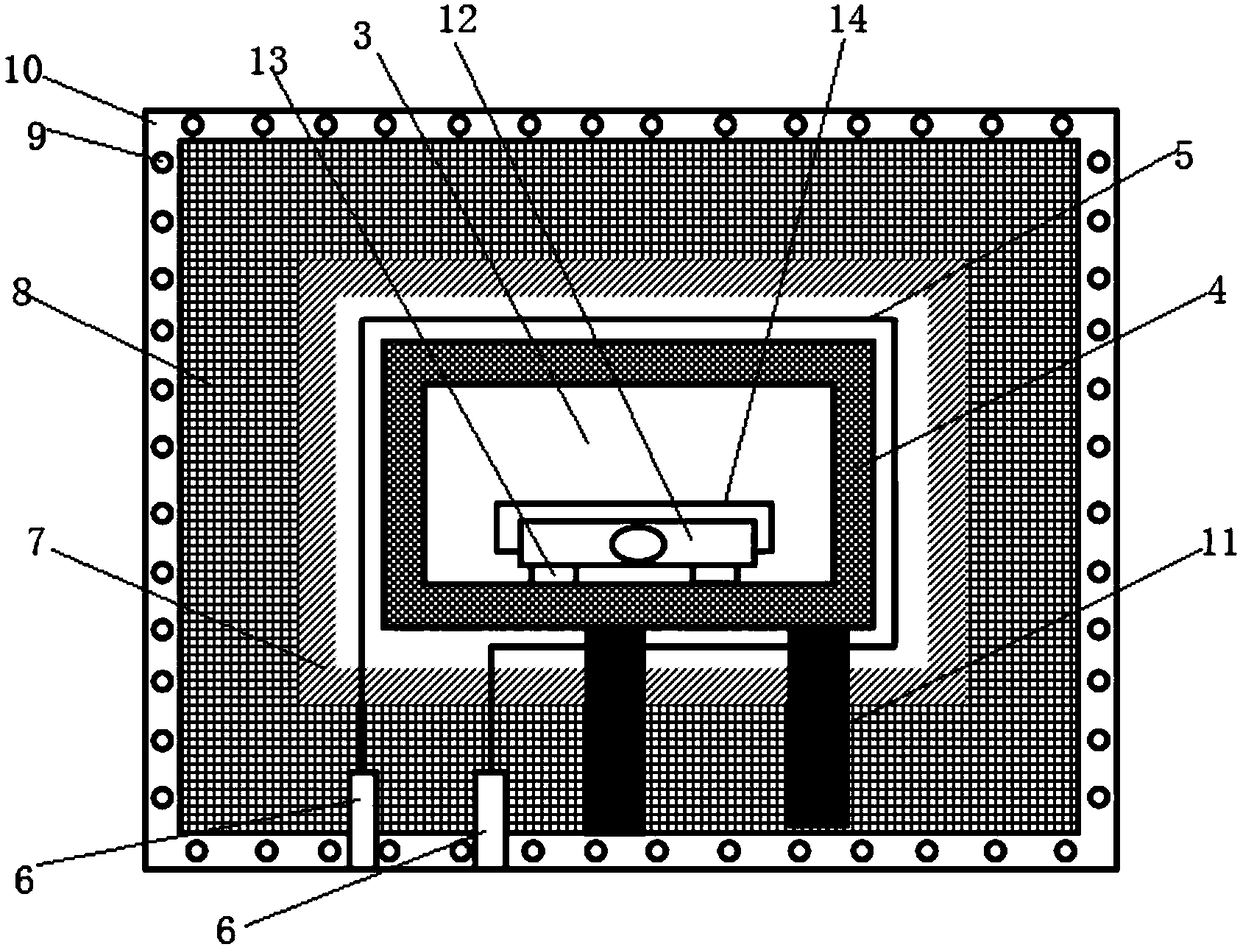

[0026] A carbon-carbon composite material high-temperature continuous heating furnace is specifically implemented as follows for processing high-purity carbon felt samples:

[0027] Such as figure 1 , first, put the high-purity carbon felt sample to be processed in the tray 14, put multiple trays on the guide rail 13 in the muffle structure furnace cavity 3, and push them into the muffle structure furnace cavity 3 through the manual mechanical push-pull device 12 In the process, the inert gas sealed chamber 1 at both ends is connected with the main body heating furnace 2 to form a closed passage, filled with argon gas with a purity of 99.999% or more for protection.

[0028] After the gas pressure is stabilized, the heating element 5 is turned on and the temperature is raised to 2300° C. to complete the high-temperature treatment process for the high-purity carbon felt sample. The entire treatment process ensures that the copper electrode 6 and the cooling water in the furnace...

Embodiment 2

[0031] A carbon-carbon composite material high-temperature continuous heating furnace specifically implements the processing of high-density carbon-carbon composite material samples, including:

[0032] First, put the high-density carbon-carbon composite material sample to be processed in the tray 14, put multiple trays on the guide rail 13 in the muffle structure furnace cavity 3, and push them into the muffle structure furnace cavity through the manual mechanical push-pull device 12 In step 3, the inert gas sealed chamber 1 at both ends is connected to the main body heating furnace 2 to form a closed passage, filled with argon gas with a purity of more than 99.999% for protection.

[0033] After the gas pressure is stabilized, the heating element 5 is turned on and the temperature is raised to 2800° C. to complete the high-temperature treatment process of the high-density carbon-carbon composite material sample. The entire treatment process ensures the smooth flow of cooling ...

Embodiment 3

[0036] A specific implementation of the high-purity titanium carbide sample processing in a carbon-carbon composite material high-temperature continuous heating furnace includes:

[0037] First, put the titanium dioxide and carbon black powder samples to be processed in the tray 14, put multiple trays on the guide rail 13 in the muffle structure furnace cavity 3, and push them into the muffle structure furnace cavity through the manual mechanical push-pull device 12 In step 3, the inert gas sealed chamber 1 at both ends is connected to the main body heating furnace 2 to form a closed passage, filled with nitrogen protection with a purity of more than 99.999%.

[0038] After the gas pressure is stabilized, turn on the heating element 5 and raise the temperature to 1500° C. to complete the high-temperature treatment process of the titanium dioxide and carbon black powder samples. During the whole treatment process, the copper electrode 6 and the cooling water in the furnace shell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com