Glass element and use thereof, coating agent for production thereof and method for production thereof

A coating agent, glass technology, applied in the direction of coating, etc., can solve the problems of improving the mechanical strength of coated glass plates that have not been mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

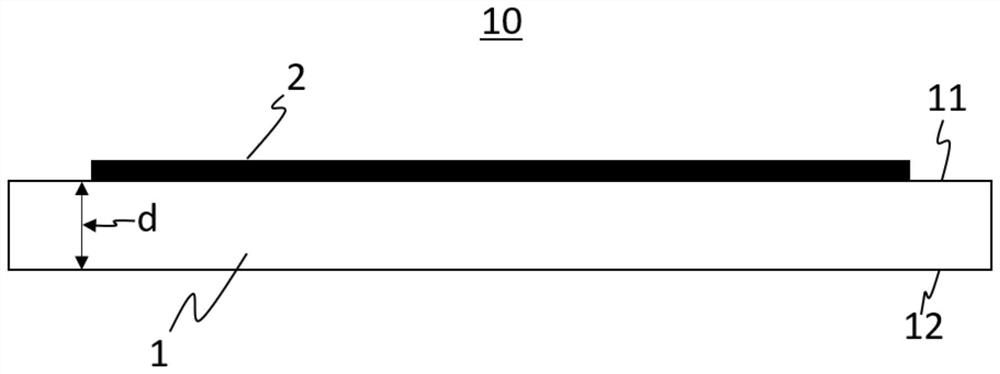

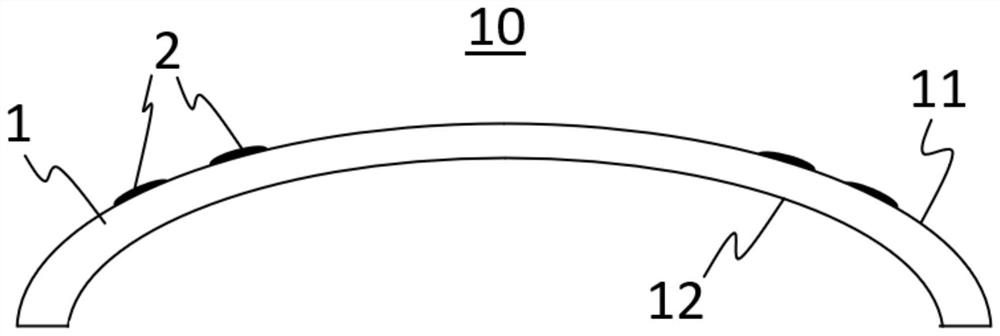

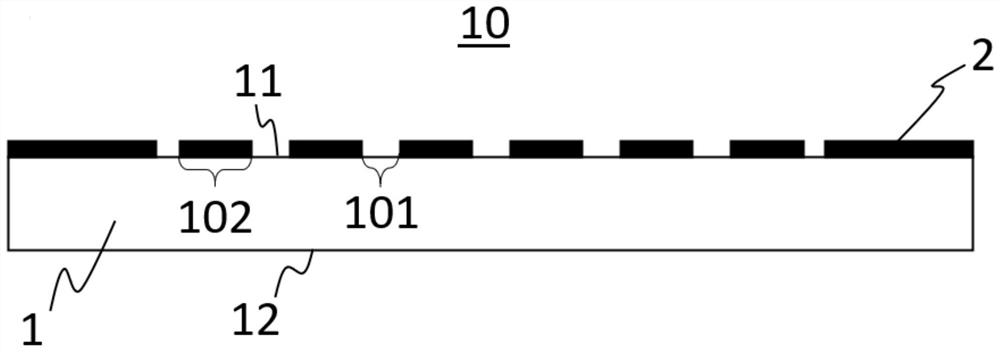

[0146] figure 1 The first schematic view of a glass element 10 comprising a sheet glass substrate 1 is not shown to scale. In this figure, the sheet glass substrate 1 is flat, ie not curved. The sheet glass substrate 1 has a first surface 11 and a second surface 12 opposite to the first surface 11 . These surfaces can in turn be referred to as sides or sides and represent the so-called main faces of the glass substrate 1 or of the corresponding glass element 10 since together they constitute more than 50% of the substrate surface. In addition, the glass substrate 1 has a thickness d. The thickness of the glass substrate 1 can also be approximately assumed to be the thickness of the glass element 10, since unlike what is currently illustrated for reasons of better understanding, the thickness of the coating 2 (without markings) is extremely large compared to the thickness of the glass substrate 1. Small. The coating 2 is arranged at least regionally on at least one of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com