High- rigidity and weather-resistant PCT/ASA (poly(1,4cyclohexylenedimethylene terephthalate)/acrylonitrile-styrene-acrylate) alloy

A high-rigidity, alloy technology, applied in the field of high-rigidity weather-resistant PCT/ASA alloys, can solve the problems of not being suitable for weather-resistant use, poor cold resistance, and material performance degradation, so as to improve the range of product use, excellent mechanical rigidity, and material compatibility. sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

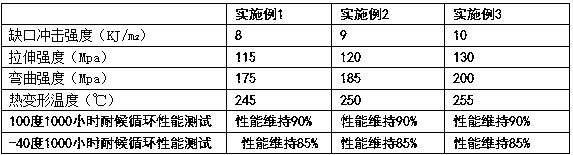

Examples

Embodiment 1

[0037] A high-rigidity weather-resistant PCT / ASA alloy comprises the following components in parts by weight:

[0038] Polyethylene terephthalate 1,4 cyclohexane dimethanol (PCT resin) 47.5 parts

[0039] Acrylonitrile-styrene-acrylate graft copolymer (ASA) 15 parts

[0040] 35 parts glass fiber

[0041] Metal deactivator 0.1 part

[0042] Nano zinc sulfide 0.5 parts

[0043] Antioxidant 1010 0.02 parts

[0044] Antioxidant 168 0.02 parts

[0045] Heat stabilizer 0.5 parts

[0046] Toughening compatibilizer 1 part

[0047] Lubricant 0.5 part.

[0048] Specifically, the glass fiber is polyester staple fiber, and the glass fiber used is imported polyester special short fiber, which effectively increases the fiber content and has a good dispersion effect.

[0049] Specifically, the heat stabilizer is isooctyl tin dimethyl dimercaptoacetate, which achieves a high-temperature stabilizing effect.

[0050] Specifically, the metal deactivator is a sulfur phenyl phosphite meta...

Embodiment 2

[0059] The difference between this embodiment and Embodiment 1 is that a high-rigidity weather-resistant PCT / ASA alloy includes the following components in parts by weight:

[0060] Polyethylene terephthalate 1,4 cyclohexane dimethanol (PCT resin) 43 parts

[0061] Acrylonitrile-styrene-acrylate graft copolymer (ASA) 15 parts

[0062] 40 parts glass fiber

[0063] Metal deactivator 0.15 parts

[0064] Nano zinc sulfide 0.5 parts

[0065] Antioxidant 1010 0.02 parts

[0066] Antioxidant 168 0.02 parts

[0067] Heat stabilizer 0.8 parts

[0068] Toughening compatibilizer 1 part

[0069] Lubricant 0.8 parts.

[0070] The present invention also discloses a method for preparing the PCT / ASA alloy, comprising the following steps:

[0071](1) Prepare raw materials: 43 parts by weight of poly-1,4-cyclohexanedimethanol terephthalate (PCT resin), 15 parts of acrylonitrile-styrene-acrylate graft copolymer (ASA), 40 parts of glass fiber, 0.15 part of metal passivator, 0.5 part of ...

Embodiment 3

[0076] The difference between this embodiment and Embodiment 1 is that a high-rigidity weather-resistant PCT / ASA alloy includes the following components in parts by weight:

[0077] Polyethylene terephthalate 1,4 cyclohexane dimethanol (PCT resin) 37 parts

[0078] Acrylonitrile-styrene-acrylate graft copolymer (ASA) 15 parts

[0079] 45 parts glass fiber

[0080] Metal deactivator 0.2 parts

[0081] Nano zinc sulfide 0.5 parts

[0082] Antioxidant 1010 0.02 parts

[0083] Antioxidant 168 0.02 parts

[0084] 1 heat stabilizer

[0085] Toughening compatibilizer 1 part

[0086] Lubricant 1 part.

[0087] The present invention also discloses a method for preparing the PCT / ASA alloy, comprising the following steps:

[0088] (1) Prepare raw materials: 37 parts by weight of poly-1,4-cyclohexanedimethanol terephthalate (PCT resin), 15 parts of acrylonitrile-styrene-acrylate graft copolymer (ASA), 45 parts of glass fiber, 0.2 part of metal passivator, 0.5 part of nano zinc su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com