High rigidity weather resistant pbt/asa alloy

A high-rigidity and weather-resistant technology, applied in the field of heat-resistant and aging-resistant high-performance engineering composite materials, can solve the problems of material performance degradation, poor rigidity effect, poor rigidity, etc., and achieve high material compatibility, good stability, and mechanical rigidity The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A high-rigidity weather-resistant PBT / ASA alloy belongs to the technical field of polymer materials, which includes the following raw materials in parts by weight: 47.5 parts of PBT polybutylene terephthalate resin, ASA acrylonitrile-styrene-acrylic acid 15 parts of ester graft copolymer, 35 parts of polyester high-strength short glass fiber, 0.1 part of metal passivator, 0.5 part of nano zinc sulfide, 10100.02 parts of antioxidant, 1680.02 parts of antioxidant, 0.5 part of heat stabilizer, 1 part of toughening compatibilizer, 0.5 part of lubricant.

Embodiment 2

[0025] A high-rigidity weather-resistant PBT / ASA alloy belongs to the technical field of polymer materials, which includes the following raw materials in parts by weight: 43 parts of PBT polybutylene terephthalate resin, ASA acrylonitrile-styrene-acrylic acid 15 parts of ester graft copolymer, 40 parts of polyester high-strength short glass fiber, 0.15 part of metal passivator, 0.5 part of nano zinc sulfide, 10100.02 parts of antioxidant, 1680.02 parts of antioxidant, 0.8 part of heat stabilizer, 1 part of toughening compatibilizer, 0.8 part of lubricant.

Embodiment 3

[0027] A high-rigidity weather-resistant PBT / ASA alloy belongs to the technical field of polymer materials, which includes the following raw materials in parts by weight: 37 parts of PBT polybutylene terephthalate resin, ASA acrylonitrile-styrene-acrylic acid 15 parts of ester graft copolymer, 45 parts of polyester high-strength short glass fiber, 0.2 part of metal passivator, 0.5 part of nano zinc sulfide, 10100.02 parts of antioxidant, 1680.02 parts of antioxidant, 1 part of heat stabilizer, 1 part toughening compatibilizer, 1 part lubricant.

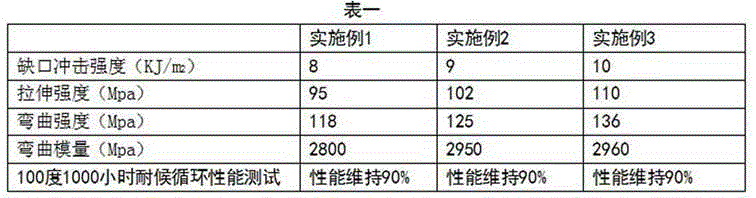

[0028] The product performance test of Examples 1-3 of the present invention, the test results are shown in Table 1.

[0029]

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com