Carbon material film with high electric conductivity, heat conductivity and strength and preparing method thereof

A material film, carbon material technology, applied in the field of high electrical conductivity, thermal conductivity and high strength carbon material film and its preparation, can solve the problems of weak force, easy to be destroyed, mechanical strength, electrical conductivity and thermal conductivity cannot be superior at the same time, etc. To achieve good effect of improving electrical conductivity, electrical conductivity and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

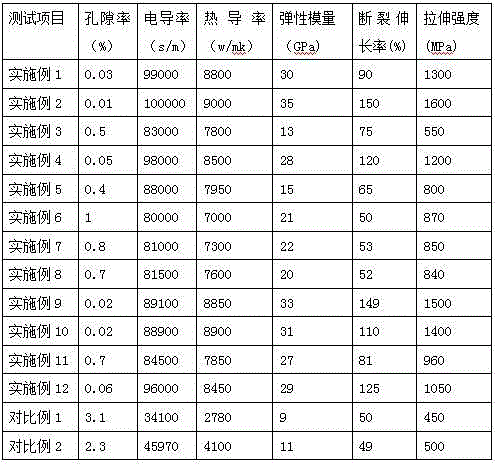

Examples

Embodiment 1

[0061] (1) Put 50 parts of hydroxylated graphite powder, 50 parts of carboxylated graphite powder, 5 parts of polymethacrylic acid and 2000 parts of water in a ball mill jar, mill for 1 hour, and then ultrasonicate for 0.2 hours to obtain carbon material dispersion;

[0062] (2) Add 0.5 parts of hydroxyethyl cellulose and 0.1 parts of dibutyl phthalate to the carbon material dispersion, and sonicate for 0.2 hours to obtain a uniform and stable slurry;

[0063] (3) When forming, apply an electric field near the base belt with an electric field strength of 20kv / m; flow the slurry from the lower part of the hopper of the tape casting equipment to the base belt, and form a blank film through the relative movement of the base belt and the scraper and control its thickness 30μm;

[0064] (4) Immerse the blank film in dichloromethane (DCM), and add 0.1 part of 2-(7-azobenzotriazole)-N,N,N',N',-tetramethylurea hexa Fluorophosphate (HATU), react at 20°C for 12 hours;

[0065] (5) Pl...

Embodiment 2

[0068] (1) Put 50 parts of aminated graphene powder and 50 parts of carboxylated graphene powder, 1 part of polyacrylic acid and 3000 parts of ethanol in a ball mill jar, mill for 2 hours, and then ultrasonicate for 1 hour to obtain carbon material dispersion;

[0069] (2) Add 1 part of hydroxymethyl cellulose and 10 parts of dioctyl phthalate to the carbon material dispersion, and ultrasonicate for 2 hours to obtain a uniform and stable slurry;

[0070] (3) Forming, the slurry is flowed from the lower part of the hopper of the tape casting equipment to the base belt, and the blank film is formed through the relative movement of the base belt and the scraper and its thickness is controlled to 1 μm;

[0071] (4) Immerse the base film in methanol, add 5 parts of 4-dimethylaminopyridine (DMAP), and react at 30°C for 4 hours; at the same time, apply an electric field in the mixed solution with an electric field strength of 1kv / m;

[0072] (5) Place the reacted blank film in the d...

Embodiment 3

[0075] (1) Put 50 parts of aminated carbon nanotube powder and 50 parts of epoxidized carbon nanotube powder, 3 parts of phosphoric acid ester and 6000 parts of trichlorethylene in a ball mill jar, ball mill for 5 hours, and then pass Ultrasound for 0.5 hours to obtain a carbon material dispersion;

[0076] (2) Add 10 parts of styrene-acrylic latex and 1 part of diethyl oxalate into the carbon material dispersion, and ultrasonicate for 1 hour to obtain a uniform and stable slurry;

[0077] (3) Forming, the slurry is flowed from the lower part of the hopper of the tape casting equipment to the base belt, and the blank film is formed through the relative movement of the base belt and the scraper and its thickness is controlled to 100 μm;

[0078] (4) Immerse the base film in sodium carbonate and react at 50°C for 5 hours;

[0079] (5) Place the reacted blank film in the drying room to evaporate the solvent; the temperature of the drying room is divided into three sections: 50°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com