Sealant for equipment installation of water conservancy and hydropower engineering

A technology of engineering equipment, water conservancy and hydropower, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve problems such as poor use effect and performance that cannot meet the requirements, and achieve convenient processing and use, high pressure resistance and sealing, The effect of improving product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

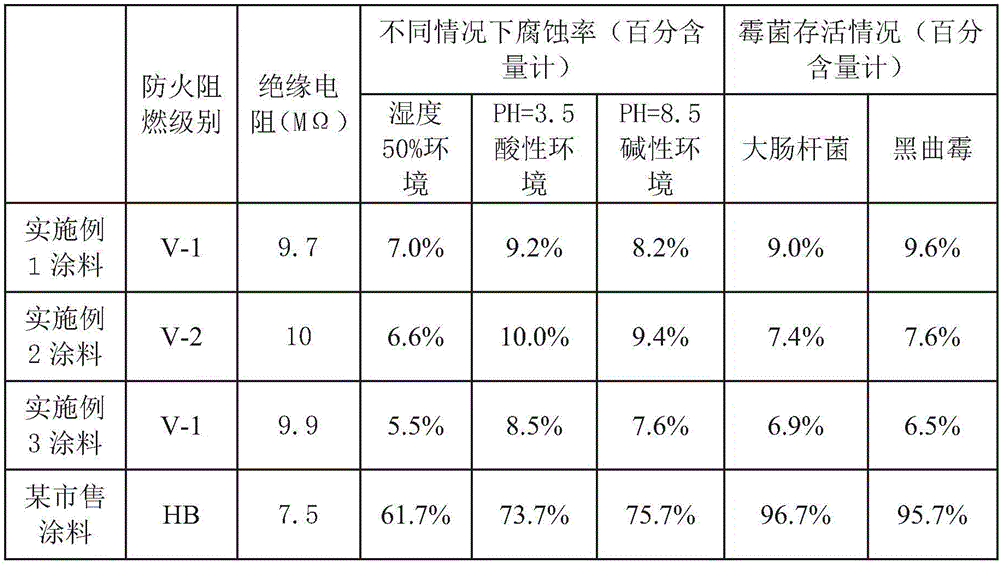

Embodiment 1

[0017] The sealant for water conservancy and hydropower engineering equipment installation in this embodiment is composed of the following components in parts by mass: 14 parts of iron oxide powder, 16 parts of chromium oxide powder, 12 parts of manganese oxide powder, 10 parts of calcium chloride, sodium carbonate 16 parts, 12 parts of silicon powder, 10 parts of trimethoxysilane, 16 parts of titanium dioxide, 12 parts of methyl ethyl ketone oxime, 10 parts of bismaleimide resin, 16 parts of sodium lauryl sulfate, polyarylene 12 parts of ether nitrile, 12 parts of starch octenyl succinate, 10 parts of ethylene bis stearic acid amide, 16 parts of barium sulfate, 12 parts of triethylene glycol diisocaprylate, 10 parts of novolak epoxy resin, polyamide 16 parts, 12 parts of dioctyl sebacate, 10 parts of triethyl phosphite, 16 parts of dimethylethanolamine, 12 parts of aluminum silicate, 10 parts of sodium hydroxymethyl cellulose, 16 parts of imidacloprid, polyoxyethylene ether 1...

Embodiment 2

[0024] The sealant for water conservancy and hydropower engineering equipment installation in this embodiment is composed of the following components in parts by mass: 16 parts of iron oxide powder, 18 parts of chromium oxide powder, 14 parts of manganese oxide powder, 12 parts of calcium chloride, sodium carbonate 18 parts, 14 parts of silicon powder, 12 parts of trimethoxysilane, 18 parts of titanium dioxide, 14 parts of methyl ethyl ketone oxime, 12 parts of bismaleimide resin, 18 parts of sodium lauryl sulfate, polyarylene 14 parts of ether nitrile, 14 parts of starch octenyl succinate, 12 parts of ethylene bis stearic acid amide, 18 parts of barium sulfate, 14 parts of triethylene glycol diisocaprylate, 12 parts of novolak epoxy resin, polyamide 18 parts, 14 parts of dioctyl sebacate, 12 parts of triethyl phosphite, 18 parts of dimethylethanolamine, 14 parts of aluminum silicate, 12 parts of sodium hydroxymethyl cellulose, 18 parts of imidacloprid, polyoxyethylene ether 1...

Embodiment 3

[0031] The sealant for water conservancy and hydropower engineering equipment installation in this embodiment is composed of the following components in parts by mass: 18 parts of iron oxide powder, 20 parts of chromium oxide powder, 16 parts of manganese oxide powder, 14 parts of calcium chloride, sodium carbonate 20 parts, 16 parts of silicon powder, 14 parts of trimethoxysilane, 20 parts of titanium dioxide, 16 parts of methyl ethyl ketone oxime, 14 parts of bismaleimide resin, 20 parts of sodium lauryl sulfate, polyarylene 16 parts of ether nitrile, 16 parts of starch octenyl succinate, 14 parts of ethylene bis stearic acid amide, 20 parts of barium sulfate, 16 parts of triethylene glycol diisocaprylate, 14 parts of novolak epoxy resin, polyamide 20 parts, 16 parts of dioctyl sebacate, 14 parts of triethyl phosphite, 20 parts of dimethylethanolamine, 16 parts of aluminum silicate, 14 parts of sodium hydroxymethyl cellulose, 20 parts of imidacloprid, polyoxyethylene ether 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com