Photoelectric transistor based on GeSn materials and manufacturing method thereof

A technology of phototransistor and manufacturing method, applied in the field of electronics, can solve the problems of low light sensitivity and photocurrent, low light absorption coefficient, narrow detection range, etc., and achieve high light absorption efficiency, high absorption coefficient, high detection photocurrent and light sensitivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

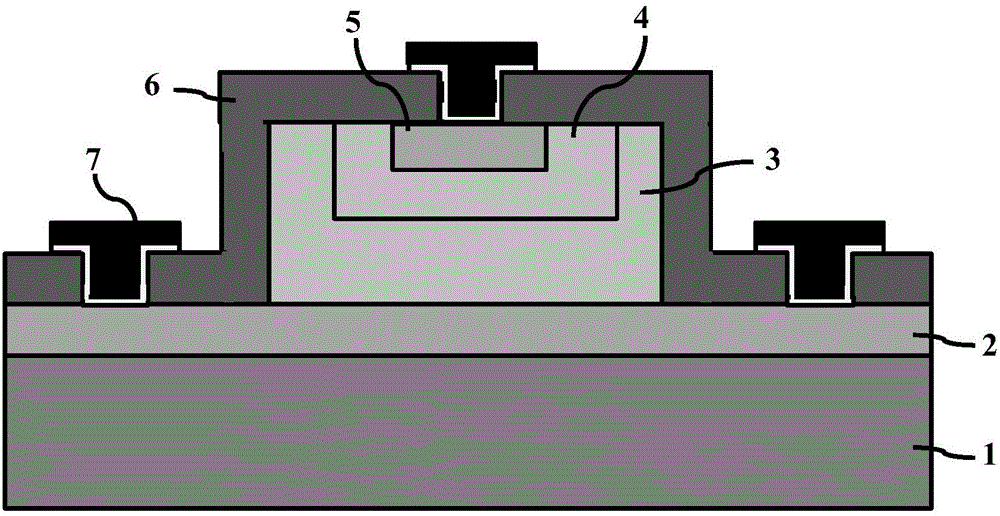

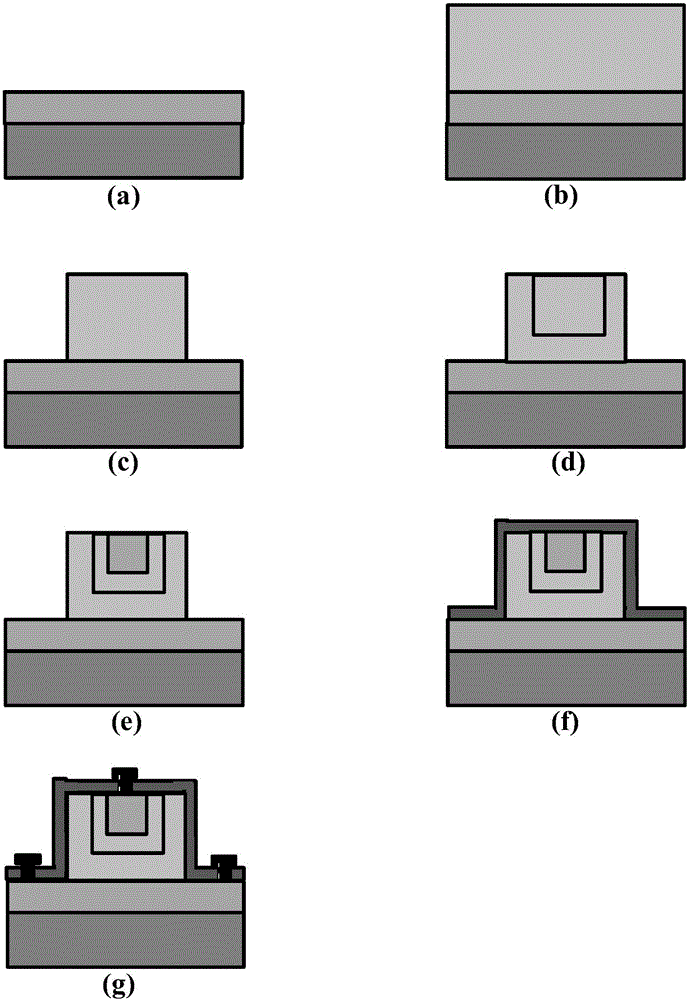

[0036] Embodiment 1: making Ge 0.935 sn 0.065 npn type phototransistor.

[0037] Step 1: Growing the collector region.

[0038] Using a low-temperature solid-source molecular beam epitaxy process, on an undoped (100) Ge substrate 1 at a temperature of 150° C., 200 nm of undoped pure Ge material is epitaxially grown as a Ge buffer layer.

[0039] On the Ge buffer layer, use high-purity Ge and Sn sources at 150°C to epitaxially generate 100nm Ge 0.935 sn 0.065 layer.

[0040]At an energy of 30Ke3V and an implant dose of 10 15 cm -2 , Implanting ions P(31) into the GeSn layer formed under the condition of a substrate tilt angle of 7° + , forming GeSn N + type collector area 2, such as figure 2 (a).

[0041] Step 2: Make the light absorbing area.

[0042] Using solid-source molecular beam epitaxy, the GeSn N + 220nm intrinsic Ge is grown on the collector region 2 at 150°C using high-purity Ge and Sn sources 0.935 sn 0.065 The epitaxial layer serves as the light abso...

Embodiment 2

[0053] Embodiment 2: making Ge 0.97 sn 0.03 pnp phototransistor

[0054] Step 1: growing the collector region.

[0055] Using the solid-source molecular beam epitaxy process, on the undoped (100) Si substrate 1 at a temperature of 150° C., a 200 nm undoped pure Ge material is epitaxially grown as a buffer layer.

[0056] Epitaxial Growth of 100nm Ge Using High Purity Ge and Sn Sources at 150℃ 0.97 sn 0.03 .

[0057] At an energy of 30KeV and an implant dose of 10 15 cm -2 , Implanting BF ions into the GeSn layer under the condition of a substrate tilt angle of 7° 2 + , forming GeSnP + type collector area 2, such as figure 2 (a).

[0058] Step 2: Make the light absorption area.

[0059] Using solid-source molecular beam epitaxy, the GeSnP + Epitaxial growth of 220nm intrinsic Ge on collector region 2 at 150°C 0.97 sn 0.03 The epitaxial layer serves as the GeSn light absorbing region 3, such as figure 2 (b).

[0060] Use reactive ion etching technology to etch...

Embodiment 3

[0070] Embodiment 3: making Ge 0.9 sn 0.1 npn phototransistor

[0071] Step A: Growing the collector region.

[0072] Using the solid-source molecular beam epitaxy process, on the undoped (100) Si substrate 1 at a temperature of 150° C., a 200 nm undoped pure Ge material is epitaxially grown as a buffer layer.

[0073] Epitaxial 100nm Ge on the buffer layer using the same conditions 0.9 sn 0.1 .

[0074] At an energy of 30KeV and an implant dose of 10 15 cm -2 , Implanting ions P(31) into the GeSn layer under the condition that the slice is tilted at an angle of 7° + Form GeSnN + type collector area 2, such as figure 2 (a).

[0075] Step B: Fabricate the light-absorbing region.

[0076] Using molecular beam epitaxy, the GeSn N + 220nm intrinsic Ge was grown on collector region 2 at 150°C 0.9 sn 0.1 The epitaxial layer serves as the light absorbing region 3, such as figure 2 (b).

[0077] Reactive ion etching technology is used to etch the desired pattern, suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com