Novel high-impurity copper anode mud treatment technology

A technology of copper anode slime and impurity copper, which is applied in the direction of photographic process, photographic auxiliary process, process efficiency improvement, etc., can solve the problems of increasing investment and operating cost, increasing smelting slag flotation facilities, and many impurities, so as to improve the comprehensive Economic benefits, shortened production cycle, and improved operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

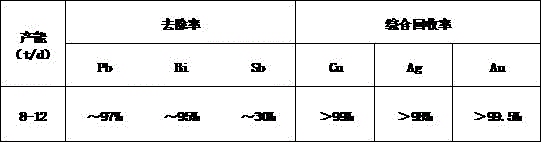

Embodiment 1

[0015] Example 1: (1), copper anode slime with Pb content of 20wt%, Bi content of 5wt%, Cu content of 11wt%, Au content of 0.09wt%, and Ag content of 3.8wt% was subjected to sulfate roasting to remove selenium and leaching to remove copper ; (2) Side-blown furnace reduction smelting: add slagging agent (soda and lime), reducing agent (coke powder and iron filings) to the copper anode slime after sulfate roasting, selenium and copper removal, and mix to obtain a mixture The dry weight of copper anode slime, slagging agent and reducing agent after sulfate roasting to remove selenium and decopper is 100:4:6, and the mixed material is added into the side-blowing furnace from the feeding port of the side-blowing furnace , and the oxygen-enriched gas and coke oven gas are sprayed into the furnace from the heating device at the side of the side-blown furnace to react with the mixed materials. The amount of oxygen-enriched gas added is 220Nm 3 / h, the amount of coke oven gas added is ...

Embodiment 2

[0016] Example 2: (1), copper anode slime with Pb content of 26wt%, Bi content of 8.8wt%, Cu content of 12.5wt%, Au content of 0.122wt%, and Ag content of 4.25wt% was subjected to sulfate roasting to remove selenium and leaching Copper removal; (2) Reduction smelting in side blowing furnace: add slagging agent (soda and lime) and reducing agent (coke powder and iron filings) to copper anode slime after sulfate roasting, selenium removal and copper removal, and mix well The mixed material is obtained, the dry weight of the copper anode slime after sulfate roasting, selenium and copper removal, the weight ratio of the slagging agent and the reducing agent is 100:5:7, and the mixed material is added from the feeding port of the side blowing furnace to the side blowing furnace. In the furnace, the oxygen-enriched gas and coke oven gas are sprayed into the furnace from the heating device at the side of the side-blown furnace to react with the mixed materials. The amount of oxygen-en...

Embodiment 3

[0017] Example 3: (1), copper anode slime with Pb content of 30wt%, Bi content of 10wt%, Cu content of 14wt%, Au content of 0.14wt%, and Ag content of 4.5wt% was subjected to sulfate roasting to remove selenium and leaching to remove copper ; (2) Side-blown furnace reduction smelting: add slagging agent (soda and lime), reducing agent (coke powder and iron filings) to the copper anode slime after sulfate roasting, selenium and copper removal, and mix to obtain a mixture The dry weight of copper anode slime, slagging agent and reducing agent after krafting and roasting to remove selenium and decopper is 100:6:9, and the mixed material is added into the side-blowing furnace from the feeding port of the side-blowing furnace , and spray oxygen-enriched gas and coke oven gas from the heating device at the side of the side-blown furnace into the furnace to react with the mixed materials. The amount of oxygen-enriched gas added is 240Nm 3 / h, the amount of coke oven gas added is 340N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com