Method for synthesizing carbyne nano-material from calcium carbide and polyhalohydrocarbon as raw materials through ball-milling

A technology of nanomaterials and polyhalogenated hydrocarbons, applied in the application of mechanochemistry in the synthesis of carbon nanomaterials, and the preparation of new alkyne carbon materials, to achieve the effects of excellent physical and chemical properties, uniform texture, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

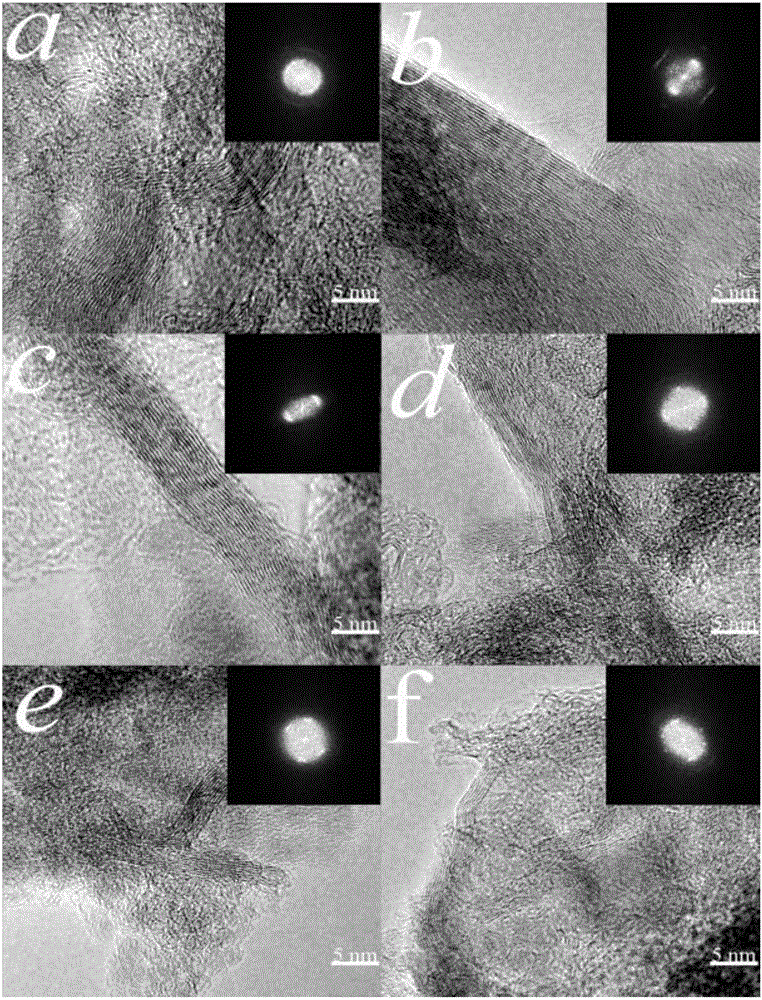

Image

Examples

Embodiment 1

[0022] Take 12 grams of 100-mesh calcium carbide (0.141mol) powder and place it in a ball mill jar, and then add 7.2 grams of carbon tetrachloride (0.047mol) to it, and the molar ratio of calcium to halogen is 1.5:2. The ball mill jar was evacuated to a vacuum of 1 kPa, and then placed in a planetary ball mill (QXQM-2, Tianchuang, Changsha). The ball mill was milled for 220 minutes under the condition of the speed of the ball mill at 530 rpm. During the operation, in order to prevent the machine from overheating, stop for 15 minutes every 45 minutes of operation. After the reaction was completed, the ball mill jar was opened, and the original gray powder turned into pitch black, which proved the generation of carbon materials. The reacted product was transferred into a beaker, treated with dilute nitric acid and the chloride ion content in the filtrate was measured, thus confirming that the dechlorination rate of carbon tetrachloride was 95.9%. After acid washing and water wa...

Embodiment 2

[0025] 16 grams of 100-mesh calcium carbide (0.188 mol) powder was placed in a crushing mill (Shanghai Lili), and then 9.85 grams of hexachloroethane (0.041 mol) was added therein three times. Add another 1 / 3 of hexachloroethane after each run for 10 minutes. The accumulative running time is 30min under the rated power. After the reaction was completed, the ball mill jar was opened, and the original gray powder turned into pitch black, which proved the generation of carbon materials. The reacted product was transferred into a beaker, treated with dilute nitric acid and the chloride ion content in the filtrate was measured, thus confirming that the dechlorination rate of hexachloroethane was 99.8%. After the product was acid-washed and washed with water, it was vacuum-dried at 130° C. for 5 hours to obtain the alkyne-carbon material of the present invention. The apparent carbon yield was 110% after weighing and calculating.

[0026] Scanning electron microscope (SEM) test res...

Embodiment 3

[0028] Take 30 grams of 100-mesh calcium carbide (0.352mol) powder and place it in a ball milling jar, then add 9.70 grams of tetrachloroethylene (0.059mol) therein, seal the ball milling jar, and protect it with atmospheric pressure argon. The ball mill jar was placed in a planetary ball mill (QXQM-2, Changsha Tianchuang), and the ball milled at a speed of 530 rpm for 260 minutes. During the operation, the machine was stopped for 15 minutes every 45 minutes to prevent overheating. After the reaction was completed, the ball mill tank was opened to find that the original gray reaction material had turned into a black powder, which proved the generation of carbon materials. Transfer the reacted product into a beaker, treat it with dilute nitric acid and measure the chloride ion content in the filtrate, the dechlorination rate of tetrachlorethylene is 100%. After the product was acid-washed and washed with water, it was vacuum-dried at 130° C. for 5 hours to obtain the alkyne car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com