Short fiber-silicon carbide nanofiber reinforced silicon carbide porous ceramic material and preparation method thereof

A technology of nanofibers and porous ceramics, which is applied in the field of short fiber-silicon carbide nanofiber reinforced silicon carbide porous ceramic materials and its preparation, which can solve the problems of high brittleness of porous ceramics, reduce corrosion damage, avoid delamination, and protect integrity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

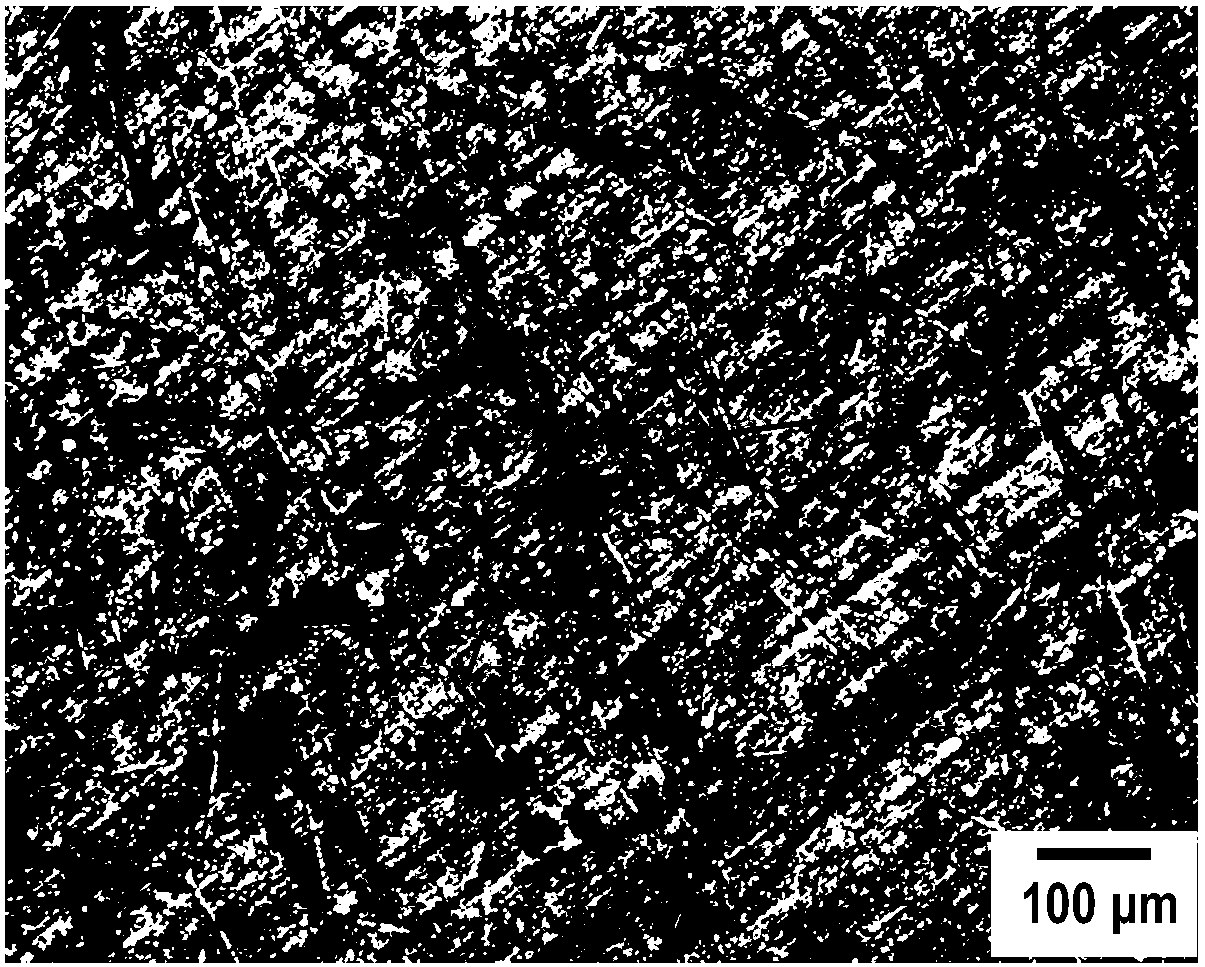

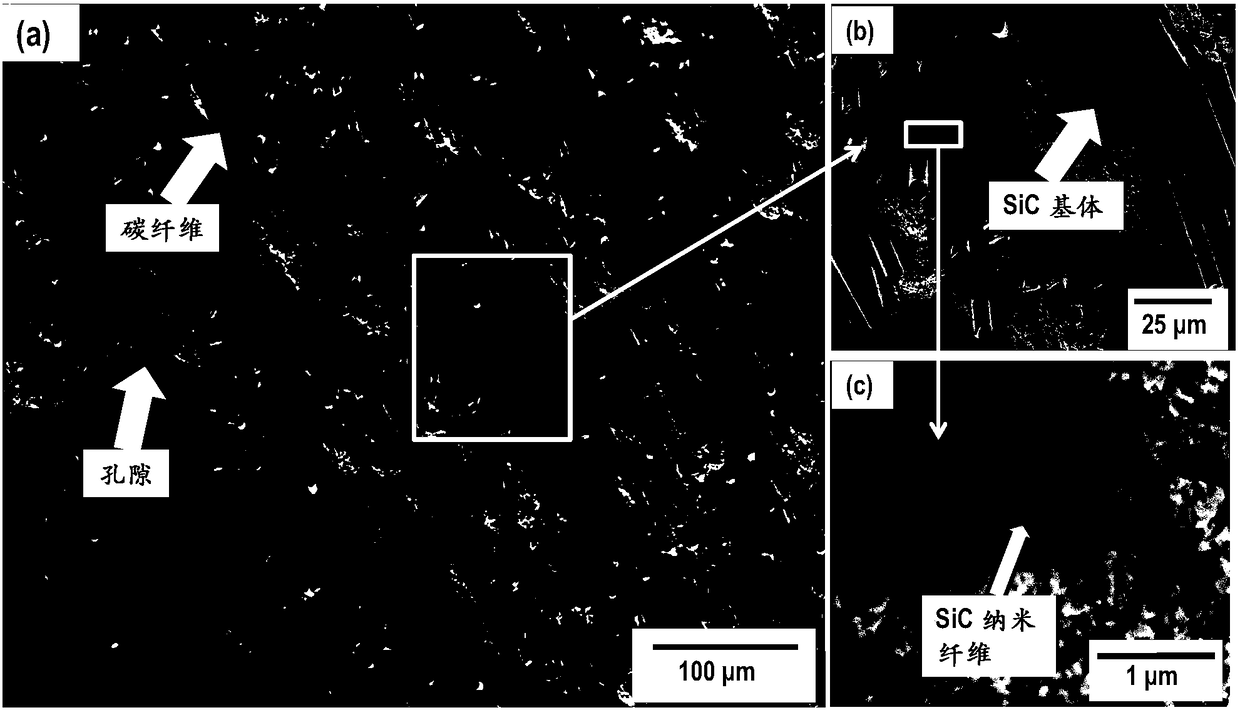

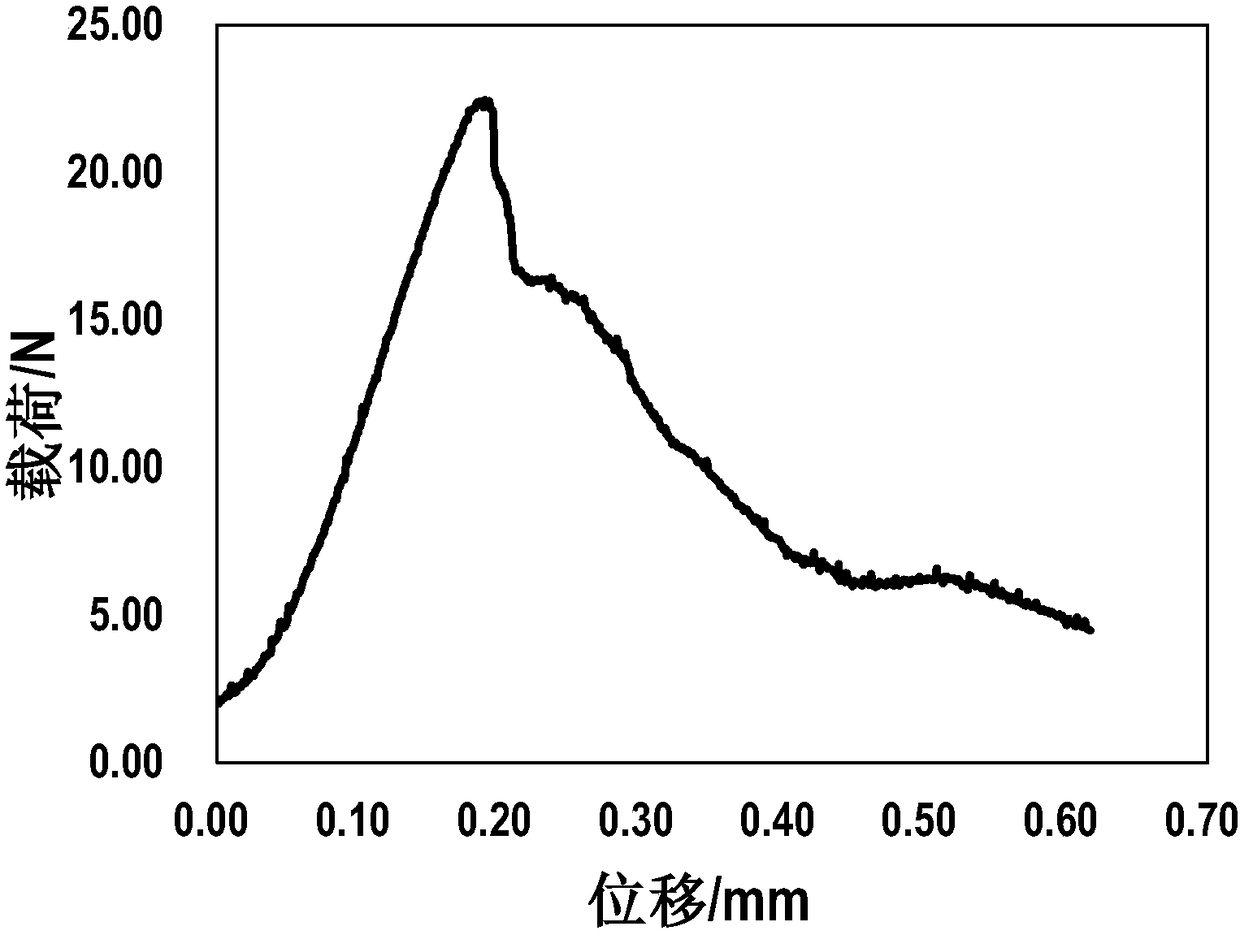

[0032] Embodiment 1: the preparation method of short fiber-silicon carbide nanofiber reinforced silicon carbide porous ceramic material comprises the following steps:

[0033] (1) 7g of silicon powder and 2g of activated carbon powder (Aladdin's reagent) were mixed and ball milled. The ball milling parameter was 150r / min, and the ball milling time was 24 hours. (2) Weigh about 5g of phenolic resin, add about 6.25g of dehydrated alcohol to be configured into a solution, add 10ml of hydroxyethyl cellulose in the melt (the present invention does not limit the stirring speed and the stirring time of the dispersant ), adding 0.6 g of chopped carbon fibers, the length of which is about 1 mm. Afterwards, 2.5 g of the mixture obtained in step (1) was added to prepare a suspension, and the volume content of chopped carbon fibers in the suspension was 6%. The above-mentioned device was shaken and dispersed in ultrasonic waves, and then dried at room temperature for about 24 hours to pr...

Embodiment 2

[0037] In this embodiment, compared with Example 1, the addition of silicon powder, activated carbon powder, phenolic resin and dispersant is constant, and the only change is the addition of chopped carbon fiber. In this embodiment, the quality of chopped carbon fiber is 1.2g (The volume fraction in the suspension is 12%).

Embodiment 3

[0039] Compared with Example 1, the addition of silicon powder, activated carbon powder, phenolic resin and dispersant in this embodiment is constant, and the only change is the addition of chopped carbon fiber. In this embodiment, the quality of carbon fiber is 2g (in suspension The volume fraction in the turbid liquid is 18%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com