Efficient method for extracting sulfonamide residues in animal derived food

A sulfonamide drug and animal-derived technology, applied in solvent extraction, separation methods, chemical instruments and methods, etc., can solve the problems of sample liquid emulsification, loss of sample information, complicated operation steps, etc., and achieve mild reaction and high polymer yield High and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 (13 kinds of sulfonamide drug residue analysis in the pork sample)

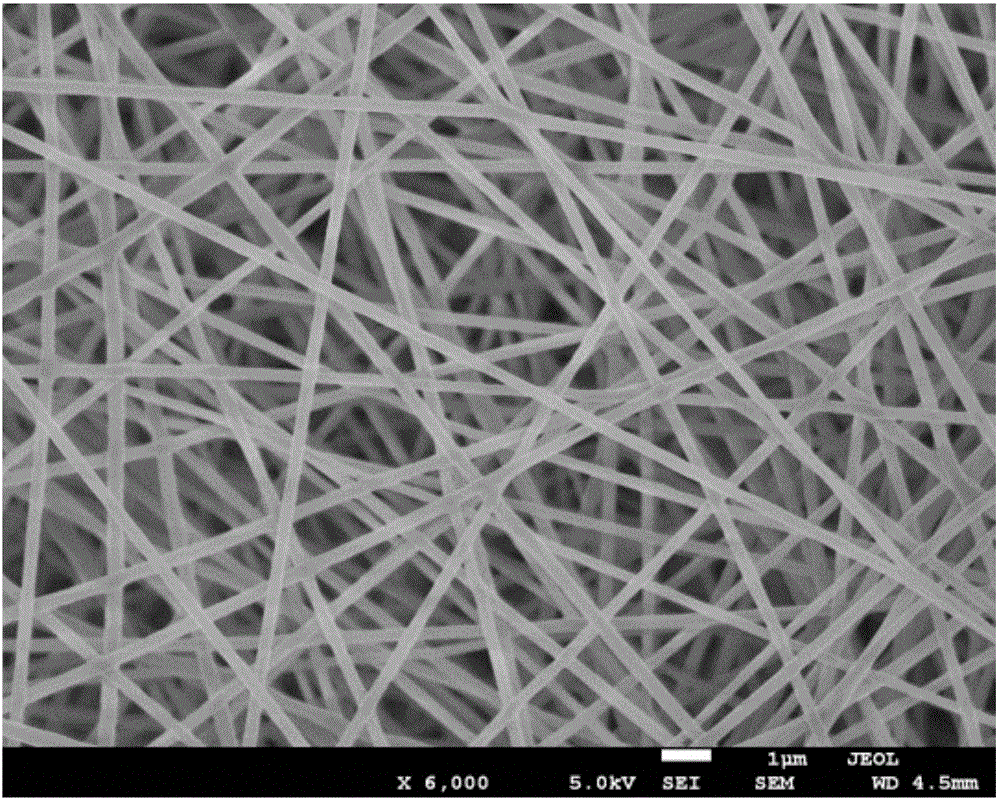

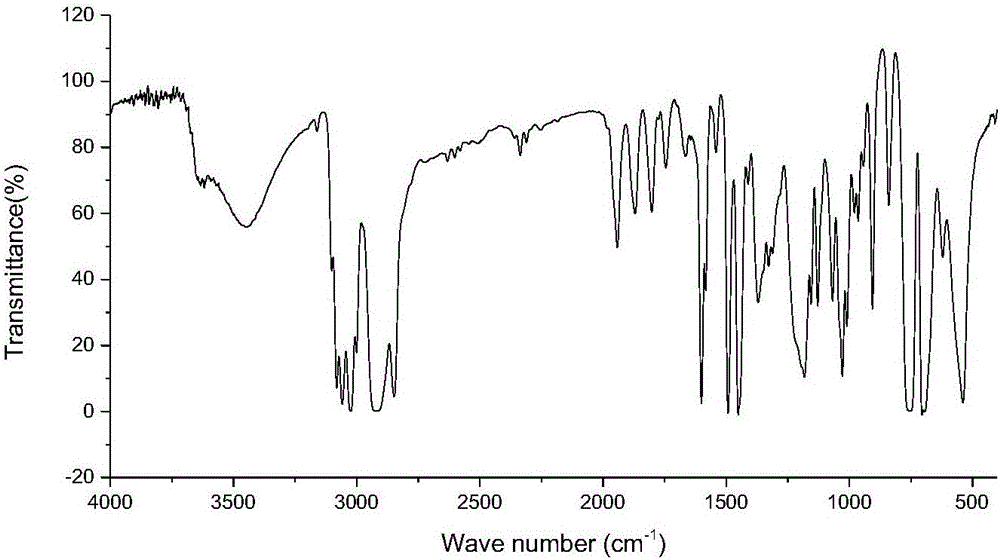

[0033] 1) Synthesis of sulfonic acid polystyrene polymer: 5.0mL styrene monomer, 1.0g sodium 4-vinylbenzenesulfonate and 0.30g sodium carbonate were placed in a triangular reaction flask, and 20mL ultrapure water was added , and reacted at 65°C with magnetic stirring for 10 minutes, then added 0.20 g of ammonium persulfate initiator, and continued to react at 65°C with magnetic stirring for 12 hours. Stop stirring after the reaction is over, cool the milky white suspension to room temperature, add 2mL formic acid to break the emulsion, mix well and let it stand for a while, centrifuge (16000r / min, 30min), discard the supernatant, take the lower layer and put it in The beaker is washed with water and placed in a vacuum drying oven to dry at 55°C, ground into powder, and then the above washing-drying-grinding steps are repeated twice to obtain the final product.

[0034] 2) Preparation of p...

Embodiment 2

[0052] Embodiment 2 (13 kinds of sulfonamide drug residue analysis in the chicken sample)

[0053] 1) Synthesis of sulfonic acid-based polystyrene polymer: 2.5mL styrene monomer, 0.5g sodium 4-vinylbenzenesulfonate and 0.15g sodium carbonate were placed in a triangular reaction flask, and 10mL ultrapure water was added , and reacted at 75°C with magnetic stirring for 10 minutes, then added 0.20 g of sodium persulfate initiator, and continued to react at 75°C with magnetic stirring for 24 hours. Stop stirring after the reaction is over, cool the milky white suspension to room temperature, add 1mL acetic acid to break the emulsion, mix well and let it stand for a while, centrifuge (14000r / min, 30min), discard the supernatant, take the lower layer and put it in The beaker is washed with water and placed in a vacuum drying oven to dry at 60°C, ground into powder, and then the above washing-drying-grinding steps are repeated twice to obtain the final product.

[0054]2) Preparatio...

Embodiment 3

[0060] Embodiment 3 (13 kinds of sulfonamide drug residue analysis in the beef sample)

[0061] 1) Synthesis of sulfonic acid polystyrene polymer: 5.0mL styrene monomer, 1.0g sodium 4-vinylbenzenesulfonate and 0.30g sodium carbonate were placed in a triangular reaction flask, and 20mL ultrapure water was added , and reacted at 65°C with magnetic stirring for 10 minutes, then added 0.20 g of ammonium persulfate initiator, and continued to react at 65°C with magnetic stirring for 12 hours. Stop stirring after the reaction is over, cool the milky white suspension to room temperature, add 2mL formic acid to break the emulsion, mix well and let it sit for a while, centrifuge (18000r / min, 30min), discard the supernatant, take the lower layer and put it in The beaker is washed with water and placed in a vacuum drying oven to dry at 55°C, ground into powder, and then the above washing-drying-grinding steps are repeated twice to obtain the final product.

[0062] 2) Preparation of pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com