A method of extracting volatile oil active components from zedoray rhizome and applications of the active components

A technology of zedoary volatile oil and active components, which is applied in the field of extracting anti-liver cancer active components, can solve the problems of complicated process, high requirements for equipment and extraction conditions, and low extraction rate, and achieve simple process, large amount of preparation, and strong anti-liver cancer active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

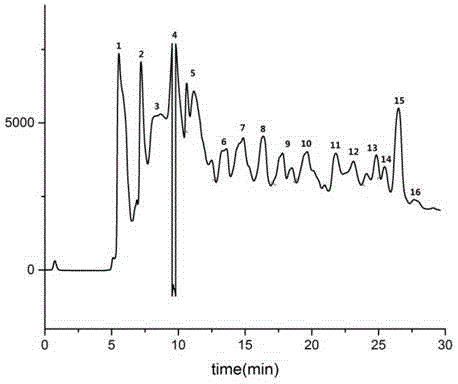

[0017] Use the dry tuber of Zedoary Curcuma as raw material, use ultrafine pulverizer to grind into powder at the temperature of -10°C, control the grinding time in 20 to 30 minutes, weigh 5kg, stir and extract with 20L 98% ethyl acetate for 10h, water bath Heating is constant at 65°C. The supernatant was collected by centrifugation, and then the extraction was repeated 3 times. The supernatant and the precipitate were collected respectively. The supernatant was combined and concentrated in a rotary evaporator, and transferred to a constant temperature blast drying oven at 60°C for drying to obtain a crude extract. The obtained crude extract was redissolved in n-hexane-ethanol binary mixed solvent system, and subjected to vacuum filtration to obtain an extract with a crude extract concentration of 100 mg / mL. The extract was separated by HPLC preparative chromatography, and the chromatographic column used was a normal phase silica gel axial pressurized chromatographic column (I...

Embodiment 2

[0019] Use the dry tuber of Zedoary Curcuma as raw material, use ultrafine pulverizer to grind into powder at the temperature of -10°C, control the grinding time in 20 to 30 minutes, weigh 5kg, stir and extract with 20L 98% ethyl acetate for 10h, water bath Heating is constant at 65°C. The supernatant was collected by centrifugation, and then the extraction was repeated 3 times. The supernatant and the precipitate were collected respectively. The supernatant was combined and concentrated in a rotary evaporator, and transferred to a constant temperature blast drying oven at 60°C for drying to obtain a crude extract. The obtained crude extract was redissolved in n-hexane-ethanol binary mixed solvent system, and subjected to vacuum filtration to obtain an extract with a crude extract concentration of 100 mg / mL. The extract was separated by HPLC preparative chromatography, and the chromatographic column used was a normal phase silica gel axial pressurized chromatographic column (I...

Embodiment 3

[0021] Use the dry tuber of Zedoary Curcuma as raw material, use ultrafine pulverizer to grind into powder at the temperature of -10°C, control the grinding time in 20 to 30 minutes, weigh 5kg, stir and extract with 20L 98% ethyl acetate for 10h, water bath Heating is constant at 65°C. The supernatant was collected by centrifugation, and then the extraction was repeated 3 times. The supernatant and the precipitate were collected respectively. The supernatant was combined and concentrated in a rotary evaporator, and transferred to a constant temperature blast drying oven at 60°C for drying to obtain a crude extract. The obtained crude extract was redissolved in n-hexane-ethanol binary mixed solvent system, and subjected to vacuum filtration to obtain an extract with a crude extract concentration of 100 mg / mL. The extract was separated by HPLC preparative chromatography, and the chromatographic column used was a normal phase silica gel axial pressurized chromatographic column (I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com