Multi-component copolymer and its preparation method and use

A multi-component copolymer and copolymerization technology, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., can solve the problem of anti-scaling and dispersing effects that are not as good as synthetic polymers and natural polymers are unstable , easy to decompose at high temperature and other problems, to achieve the effect of improving scale inhibition and dispersing performance, narrow molecular weight distribution and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

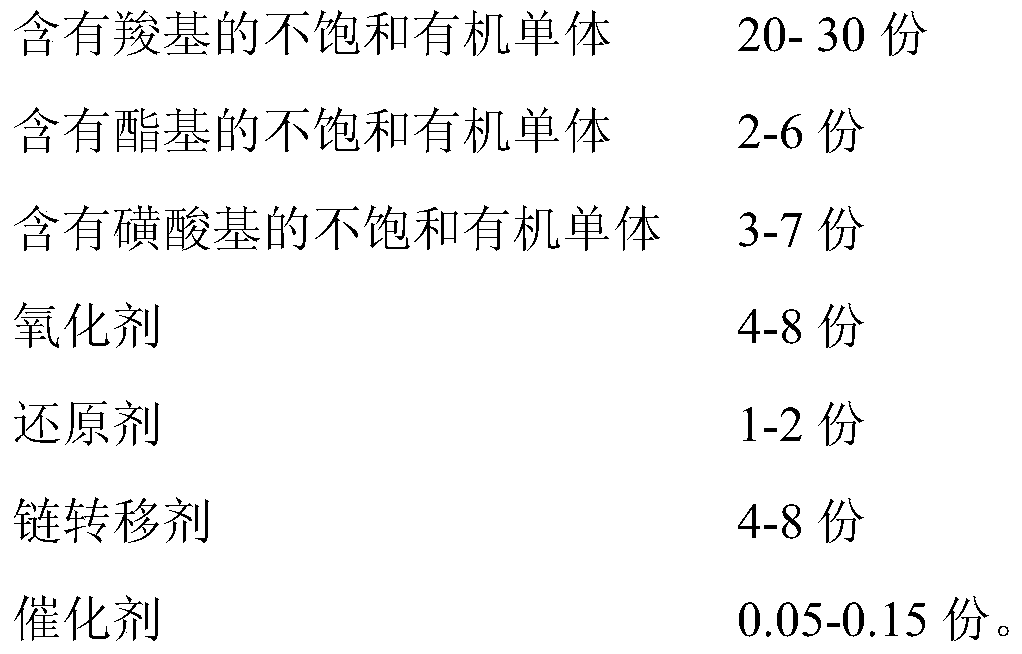

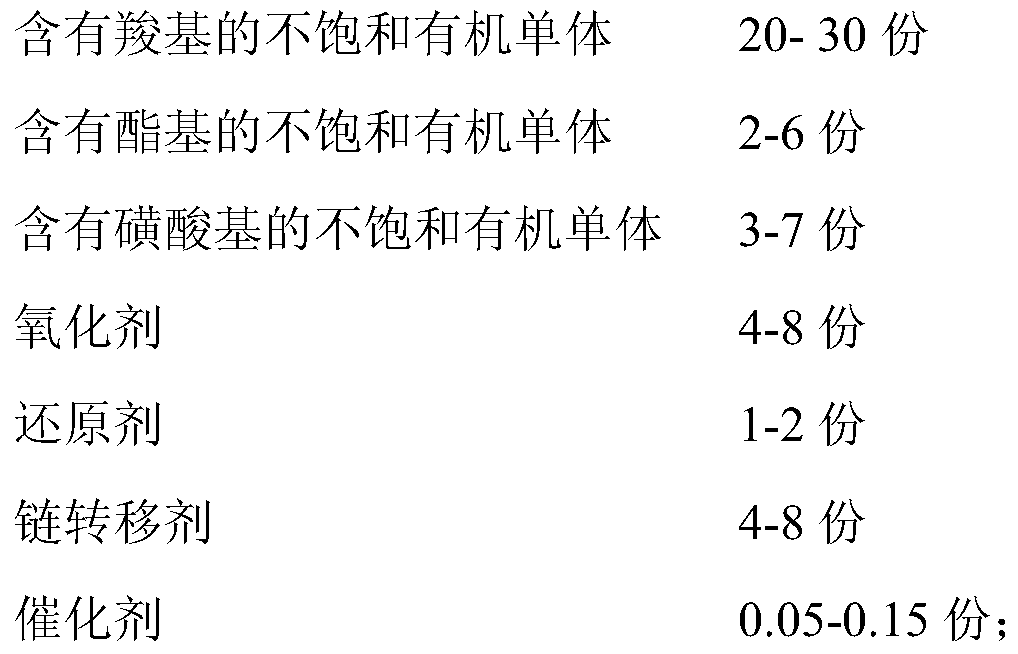

Method used

Image

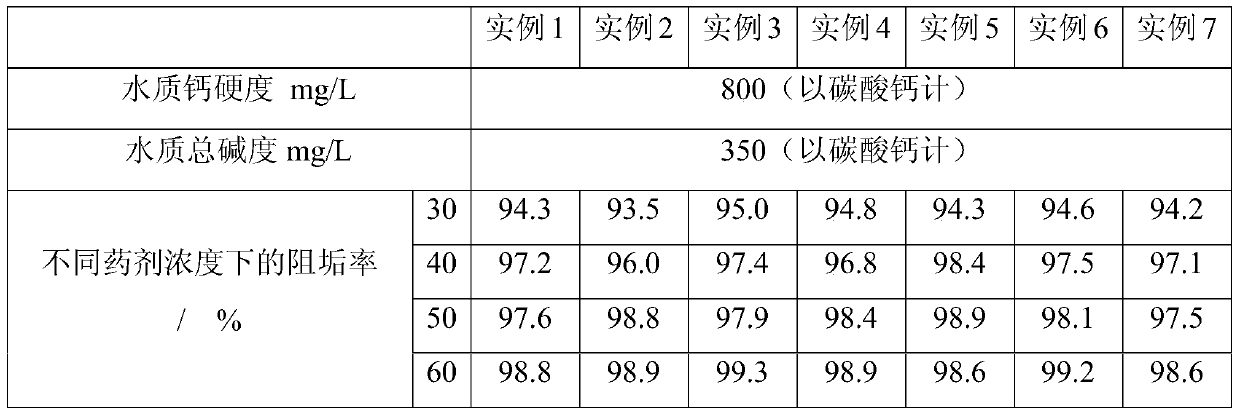

Examples

example 1

[0037] Component A: 2 parts of hydrogen peroxide (hydrogen peroxide with a content of about 27%), 2 parts of ammonium persulfate, prepared as a 40% aqueous solution;

[0038] Component B: 15 parts of acrylic acid, 5 parts of aconitic acid, 2 parts of methyl methacrylate, 2 parts of hydroxyethyl acrylate, 2 parts of hydroxypropyl acrylate, prepared as a 59% aqueous solution;

[0039] Component C: 0.5 parts of vitamin C, 0.5 parts of sodium bisulfite, 2 parts of isopropanol, 2 parts of thioglycolic acid, 0.025 parts of ferric ammonium sulfate, 0.025 parts of copper sulfate, 3 parts of sodium vinyl sulfonate, allyl sulfonate 2 parts of sodium methacrylate, 2 parts of sodium methacrylate, 34 parts of deionized water;

[0040] According to the above-mentioned C component batching method, in the reactor equipped with a reflux condenser and a stirring device, turn on the stirring device, prepare C component, and pass steam to raise the temperature after preparation. When the temperatu...

example 2

[0042] Component A: 2 parts of hydrogen peroxide (about 27% hydrogen peroxide), 2 parts of potassium persulfate, prepared as a 40% aqueous solution;

[0043] Component B: 15 parts of acrylic acid, 5 parts of itaconic acid, 5 parts of aconitic acid, 1 part of methyl acrylate, 1 part of vinyl acetate, 2 parts of hydroxypropyl methacrylate, prepared as a 54% aqueous solution;

[0044] Component C: 0.5 parts of ferrous sulfate, 0.5 parts of sodium hypophosphite, 2 parts of n-propanol, 2 parts of thioglycolic acid, 2 parts of mercaptopropanol, 0.05 parts of iron sulfate, 0.05 parts of copper sulfate, 2 parts of sodium allyl sulfonate 2 parts, 2 parts of 2-acrylamide-2-methylpropanesulfonic acid, 25 parts of deionized water;

[0045] According to the above-mentioned C component batching method, in the reactor equipped with a reflux condenser and a stirring device, turn on the stirring device, prepare C component, and pass steam to raise the temperature after preparation. When the t...

example 3

[0047] Component A: 2 parts of potassium persulfate, 2 parts of ammonium persulfate, prepared as a 50% aqueous solution;

[0048] Component B: 5 parts of acrylic acid, 15 parts of methacrylic acid, 5 parts of aconitic acid, 5 parts of itaconic acid, 1 part of methyl methacrylate, 1 part of hydroxyethyl acrylate, prepared as a 50% aqueous solution;

[0049] Component C: 0.5 parts of sodium thiosulfate, 0.5 parts of diethylamine, 2 parts of n-propanol, 2 parts of thioglycolic acid, 2 parts of mercaptopropanol, 2 parts of mercaptoethanol, 0.05 parts of ferric ammonium sulfate, 0.05 parts of iron citrate , 0.05 parts of copper sulfate, 1 part of sodium methacrylate, 1 part of 2-acrylamide-2-methylpropanesulfonic acid, 1 part of styrenesulfonic acid, 16 parts of deionized water;

[0050] According to the above-mentioned C component batching method, in the reactor equipped with a reflux condenser and a stirring device, turn on the stirring device, prepare C component, and pass steam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com