Formaldehyde-free lightweight composite board for decoration and preparation method thereof

A lightweight composite board and composite board technology, which can be used in the manufacture of fire-retardant and flame-retardant filaments, textiles, single-component polyolefin rayon, etc. Good performance, sound absorption and heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

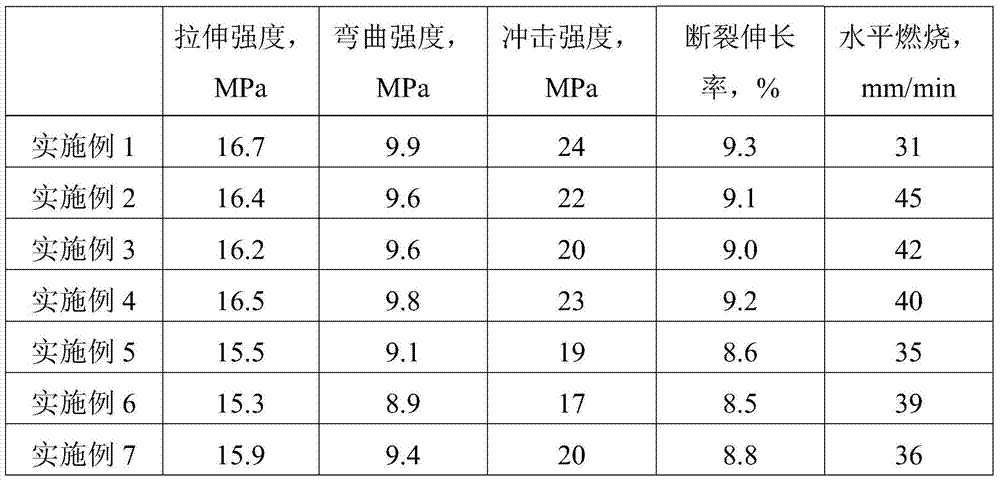

Examples

Embodiment 1

[0041] Composite board raw materials: 3kg glass fiber, 7kg flame retardant polypropylene fiber.

[0042] Flame-retardant polypropylene fiber raw materials: 7kg polypropylene chips, 0.7kg resorcinol bis[bis(2,6-dimethylphenyl)phosphate], 0.7kg resorcinol tetraphenyl diphosphate, 0.7kg Bisphenol A bis(diphenyl phosphate), 0.3kgPP-g-MAH, 0.3kgSEBS-g-MAH, 0.3kgLDPE-g-MAH.

[0043] A method for preparing a formaldehyde-free lightweight composite board for decoration, comprising the following steps:

[0044] (1) Put polypropylene slices, flame retardant, and compatibilizer into a high-speed mixer, mix evenly, add to a twin-screw extruder, and then melt and mix and granulate at a temperature of 220°C through the twin-screw extruder, The flame-retardant masterbatch is obtained; after being spun by a BCF spinning unit, the conventional polypropylene spinning process is adopted to obtain a flame-retardant polypropylene fiber with a linear density of 1350dtex / 144f.

[0045] (2) Mix the...

Embodiment 2

[0050] Formaldehyde-free lightweight composite panels for decoration are prepared according to the raw material ratio and method of Example 1, the difference is only: flame-retardant polypropylene fiber raw materials: 7kg polypropylene chips, 1.05kg resorcinol bis[bis(2,6-bis Methylphenyl) phosphate], 1.05kg resorcinol tetraphenyl diphosphate, 0.3kgPP-g-MAH, 0.3kgSEBS-g-MAH, 0.3kgLDPE-g-MAH. Obtain the formaldehyde-free lightweight composite board for decoration of embodiment 2, and the grammage is 1220g / m 2 .

Embodiment 3

[0052] Formaldehyde-free lightweight composite panels for decoration are prepared according to the raw material ratio and method of Example 1, the difference is only: flame-retardant polypropylene fiber raw materials: 7kg polypropylene chips, 1.05kg resorcinol bis[bis(2,6-bis methyl phenyl) phosphate], 1.05kg bisphenol A bis(diphenyl phosphate), 0.3kgPP-g-MAH, 0.3kgSEBS-g-MAH, 0.3kgLDPE-g-MAH. Obtain the formaldehyde-free lightweight composite board for decoration of embodiment 3, and the grammage is 1220g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com