Double-shoulder-ridge GaAs-based laser preparation method and GaAs-based laser prepared therethrough

A technology of lasers and ridges, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of increased raw material consumption, complex process, long production line time, etc., to shorten the production cycle, simplify the process steps, and reduce consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

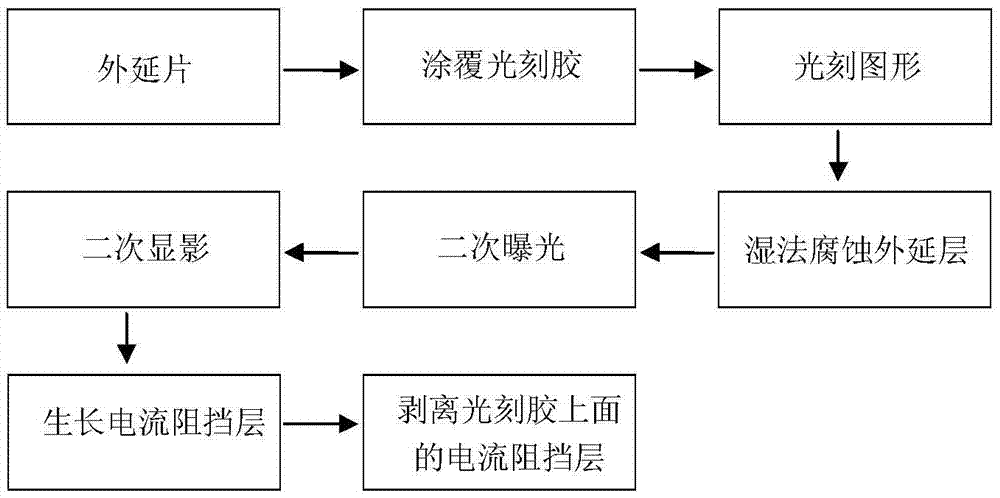

[0034] A kind of preparation method of the GaAs-base laser of double-shoulder ridge bar, comprises steps as follows:

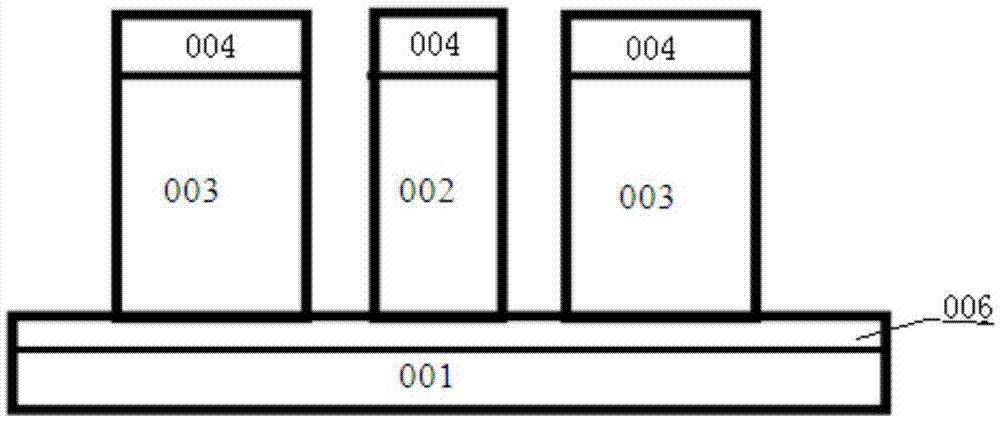

[0035] 1) Etch the epitaxial layer with a double-shoulder structure by photolithography using a photolithography mask, and etch a ridge structure 002 between the double-shoulder structures 003; the tops of the double-shoulder structure 003 and the top of the ridge structure 002 are respectively A photoresist 004 is left; the photolithography method includes steps such as exposure, development, and corrosion;

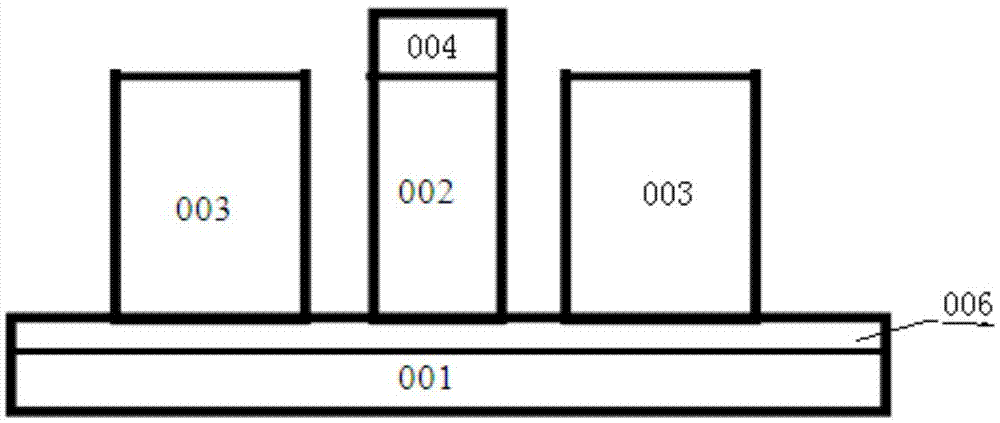

[0036] 2) Second exposure: block the photoresist 004 on the top of the ridge structure 002, and expose the photoresist on the top of the shoulder structure 003;

[0037] 3) Secondary development: remove the photoresist in the exposed part by development;

[0038] 4) growing a current blocking layer 005 on the epitaxial wafer after secondary development;

[0039] 5) Peel off the current blocking layer at the photoresist: peel off the current blocking la...

Embodiment 2

[0045] The preparation method of a kind of GaAs-based laser with double-shouldered ridges as described in Example 1, the difference is that, after the above step 5), it is also necessary to carry out P-face electrode evaporation, thinning, and N-side electrode evaporation on the epitaxial wafer. Electrode evaporation, alloying, packaging and other steps form GaAs-based lasers.

Embodiment 3

[0047] A method for preparing a GaAs-based laser with double-shouldered ridges as described in Example 1, the difference is that in the step 1), the etching of the epitaxial layer is wet etching. The corrosion solution used in the wet etching is a conventional proportion, including a mixture of analytically pure phosphoric acid, hydrogen peroxide, and deionized water, and saturated bromine water; in the mixture of phosphoric acid, hydrogen peroxide, and deionized water , Phosphoric acid: hydrogen peroxide: deionized water=1:1:(3~4) volume ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com