Polylactic acid nanometer complex concurrently having toughness and strength, and preparation method thereof

A nanocomposite, polylactic acid technology, applied in the field of polymer materials, to achieve the effect of simple process, good compatibility and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

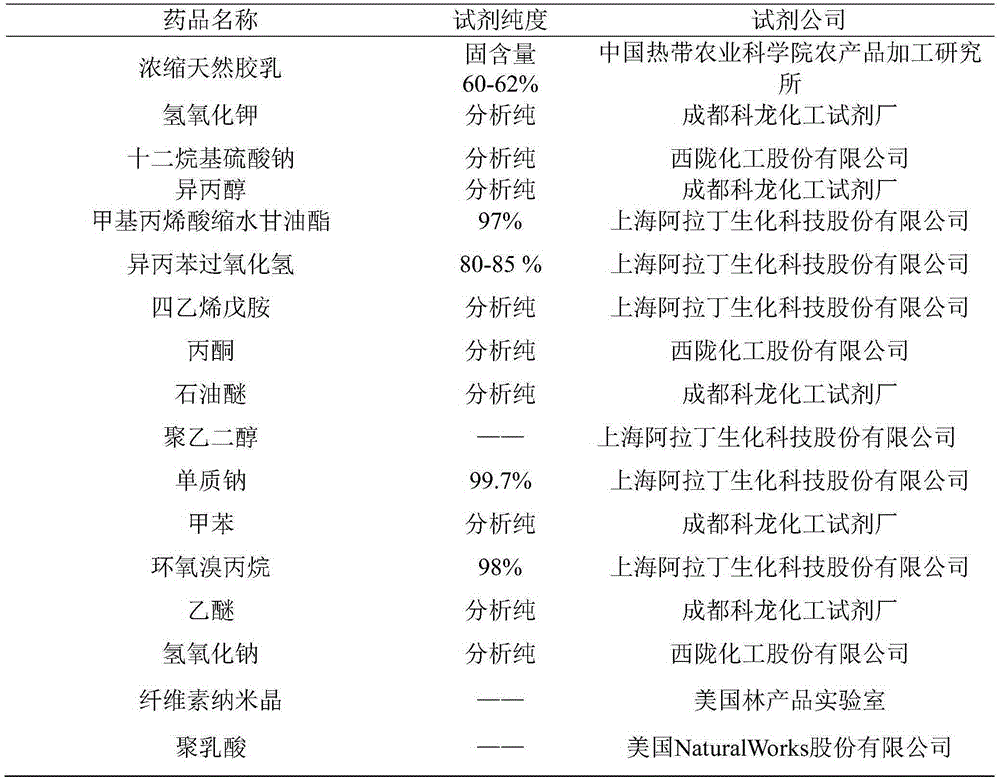

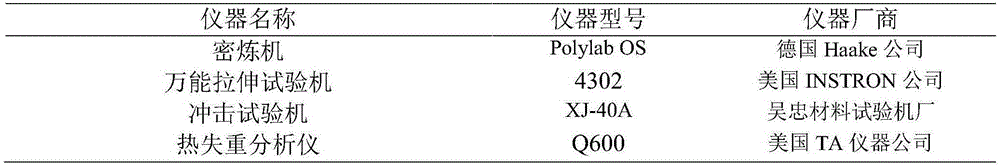

Method used

Image

Examples

Embodiment 1

[0043] A polylactic acid nano-composite having both toughness and strength, taking the total mass of the compound as 100%, each component and its mass percentage are as follows:

[0044] Polylactic acid 95%;

[0045] NR-g-GMA3%;

[0046] CNC-g-PEG2%;

[0047] Wherein, glycidyl methacrylate in the NR-g-GMA accounts for 20% of the mass of natural rubber latex; polyethylene glycol in the CNC-g-PEG accounts for 20% of the mass of cellulose nanocrystals.

[0048] A method for preparing a polylactic acid nanocomposite having both toughness and strength as described in this embodiment, the specific steps of the method are as follows:

[0049] (1) Preparation of glycidyl methacrylate-natural rubber latex graft

[0050] Add 100g of concentrated natural rubber latex into a three-necked bottle, then add 100ml of deionized water to dilute, add 10g of potassium hydroxide and 1g of sodium lauryl sulfate during stirring; pass nitrogen at room temperature, add 10g of isopropyl after 30min ...

Embodiment 2

[0057] A polylactic acid nano-composite having both toughness and strength, taking the total mass of the compound as 100%, each component and its mass percentage are as follows:

[0058] Polylactic acid 85%;

[0059] NR-g-GMA10%;

[0060] CNC-g-PEG5%;

[0061] Wherein, glycidyl methacrylate in the NR-g-GMA accounts for 40% of the mass of natural rubber latex; polyethylene glycol in the CNC-g-PEG accounts for 30% of the mass of cellulose nanocrystals.

[0062] A method for preparing a polylactic acid nanocomposite having both toughness and strength as described in this embodiment, the specific steps of the method are as follows:

[0063] (1) Preparation of glycidyl methacrylate-natural rubber latex graft

[0064] Add 100g of concentrated natural rubber latex into a three-necked bottle, then add 100ml of deionized water to dilute, add 10g of potassium hydroxide and 1g of sodium lauryl sulfate during stirring; pass nitrogen at room temperature, add 10g of isopropyl after 30min...

Embodiment 3

[0071] A polylactic acid nano-composite having both toughness and strength, taking the total mass of the compound as 100%, each component and its mass percentage are as follows:

[0072] Polylactic acid 75%;

[0073] NR-g-GMA20%;

[0074] CNC-g-PEG5%;

[0075] Wherein, glycidyl methacrylate in the NR-g-GMA accounts for 50% of the mass of natural rubber latex; polyethylene glycol in the CNC-g-PEG accounts for 50% of the mass of cellulose nanocrystals.

[0076] A method for preparing a polylactic acid nanocomposite having both toughness and strength as described in this embodiment, the specific steps of the method are as follows:

[0077] (1) Preparation of glycidyl methacrylate-natural rubber latex graft

[0078] Add 100g of concentrated natural rubber latex into a three-necked bottle, then add 100ml of deionized water to dilute, add 10g of potassium hydroxide and 1g of sodium lauryl sulfate during stirring; pass nitrogen at room temperature, add 10g of isopropyl after 30min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com