One-component transparent waterborne polyurethane emulsion waterproof paint and preparation method thereof

A technology of water-based polyurethane and waterproof coatings, which is applied in coatings and other directions, can solve the problems of small width, poor water resistance and solvent resistance, and needs to be improved in water resistance and solvent resistance, so as to achieve the effect of increasing hardness and improving hydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

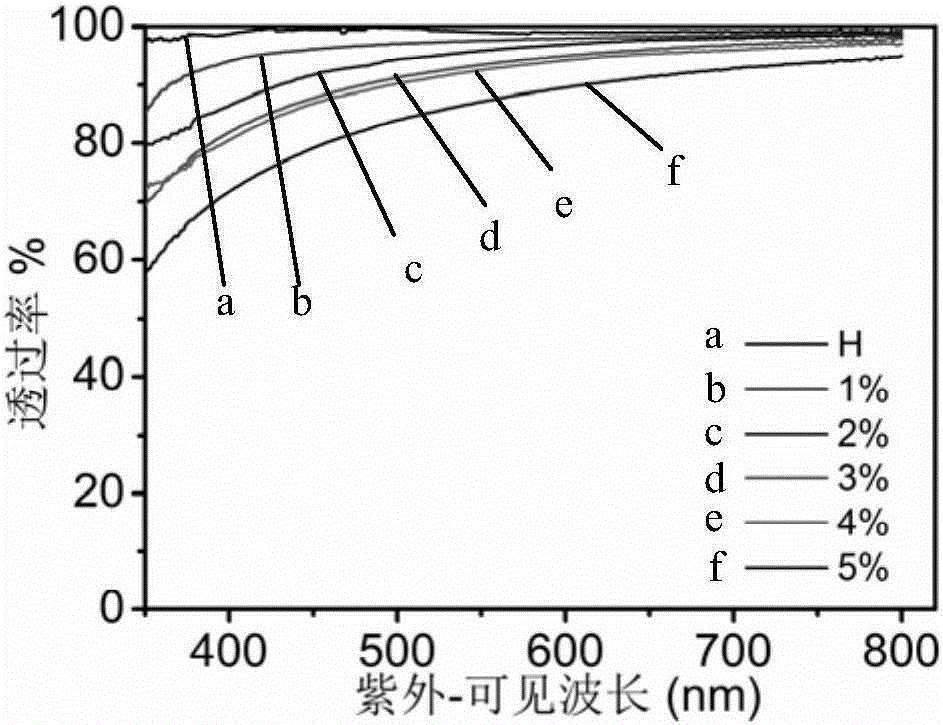

[0059] The one-component transparent water-based polyurethane emulsion waterproof coating of the present invention is prepared from the following raw materials according to mass percentage: 20% of isophorone diisocyanate, 60% of polypropylene glycol, 0.05% of dibutyltin dilaurate, and hydroxyl-terminated polysilicon Oxane 3%, Dimethylolpropionic Acid 3.5%, Hydroxyethyl Acrylate 3.2%, Methylpropylene Glycol 3.8%, Triethylamine 6%, Trimethylolpropane Glycidyl Ether 3.3%, Ammonium Persulfate 0.5%, The solid content is 40-50%.

[0060] In the first step, add isophorone diisocyanate, polypropylene glycol (Mn=2000) and dibutyltin dilaurate into the reaction kettle, stir evenly with a mechanical stirrer, heat up to 75°C for 2 hours, and then dissolve the , Add dimethylolpropionic acid in N-dimethylformamide to the mixed system, heat to 80°C for 3 hours; cool down to 60°C, add methylpropylene glycol and hydroxyethyl acrylate to the system, keep warm to continue the reaction 4h; At th...

Embodiment 2

[0064] The preparation process of the high-transparency water-based polyurethane waterproof coating described in this example is similar to that of the example, the difference is that the raw material ratio of this example is: 30% of isophorone diisocyanate, 50% of polypropylene glycol, and hydroxyl-terminated polysilicon Oxane 6%, Dibutyltin Dilaurate 0.06%, Dimethylolpropionate 3.4%, Hydroxyethyl Acrylate 3.4%, Methylpropylene Glycol 3.8%, Triethylamine 1.4%, Trimethylolpropane Glycidyl Ether 2 %, ammonium persulfate 0.6%, solid content 40-50%.

[0065] The performance test results are shown in Table 1.

Embodiment 3

[0067]The preparation process of the transparent water-based polyurethane waterproof coating described in this example is similar to that of the example, the difference is that the raw material ratio of this example is: 26% of isophorone diisocyanate, 48% of polypropylene glycol, hydroxyl-terminated polysiloxane Alkanes 8%, Dibutyltin Dilaurate 0.04%, Dimethylolpropionic Acid 2%, Hydroxyethyl Acrylate 3%, Methylpropylene Glycol 4%, Triethylamine 4%, Trimethylolpropane Glycidyl Ether 5% , Ammonium persulfate 0.4%, solid content is 40-50%.

[0068] The performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com