Hard alloy matrix and polycrystalline diamond composite sheet

A cemented carbide substrate and polycrystalline diamond technology, applied in metal processing equipment, turning equipment, drilling/drilling equipment, etc., can solve problems such as poor impact resistance, increased cost, and insufficient bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

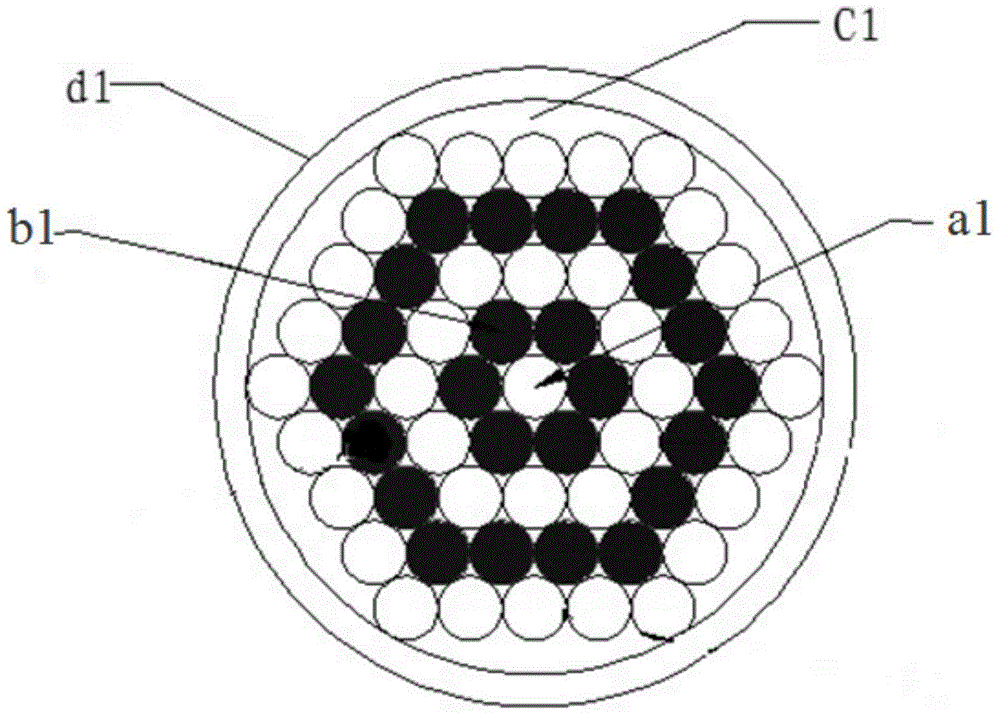

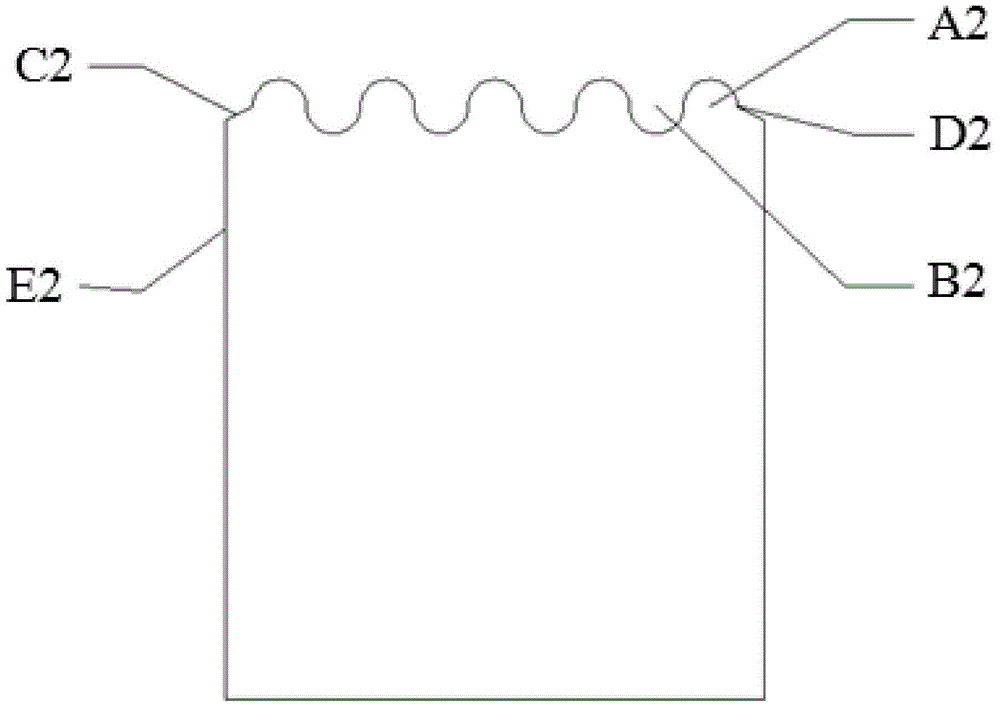

[0052] First, prepare the cemented carbide for the polycrystalline diamond composite sheet, which is in the shape of a cylinder. The interface between the cemented carbide substrate and the diamond layer is a frustum-shaped overall, and the diameter difference between the upper and lower bottom surfaces of the frustum is 1 mm, and the busbar of the frustum and the bottom surface are 1 mm apart. The included angle of the lower bottom surface is 20°. The center of the circular platform is designed as a convex hemisphere, and the concave hemisphere is circumscribed with the convex hemisphere as the center, and the convex or concave hemispheres are uniformly arranged in a regular hexagonal radial shape, and the top view and cross-sectional structure schematic diagram are respectively as follows figure 1 and figure 2 shown.

[0053] Secondly, the diamond micropowder with different particle sizes is mixed and purified, and then the processed diamond micropowder and the above-menti...

Embodiment 2

[0056] First, prepare the cemented carbide for the polycrystalline diamond composite sheet, which is in the shape of a cylinder. The interface between the cemented carbide substrate and the diamond layer is generally in the shape of a truncated cone. The included angle of the lower bottom surface is 30°. The center of the circular platform is designed as a convex hemisphere, and the concave hemisphere is circumscribed with the convex hemisphere as the center, and the convex or concave hemispheres are evenly and alternately arranged radially in the shape of a regular hexagon.

[0057] Secondly, the diamond micropowder with different particle sizes is mixed and purified, and then the processed diamond micropowder and the above-mentioned cemented carbide substrate are placed in a metal cup to obtain a combined inner core. Put the prepared combined inner core, salt tube, magnesium tube, carbon tube and other auxiliary parts into special pyrophyllite blocks to make synthetic blocks...

Embodiment 3

[0060] First, prepare the cemented carbide for the polycrystalline diamond composite sheet, which is in the shape of a cylinder. The interface between the cemented carbide substrate and the diamond layer is generally a frustum of a cone. The angle with the bottom surface is 35°. The center of the circular platform is designed as a concave hemisphere, and the convex hemisphere is circumscribed with the concave hemisphere as the center, and the convex or concave hemispheres are evenly and alternately arranged radially in the shape of a regular hexagon.

[0061] Secondly, the diamond micropowder with different particle sizes is mixed and purified, and then the processed diamond micropowder and the above-mentioned cemented carbide substrate are placed in a metal cup to obtain a combined inner core. Put the prepared combined inner core, salt tube, magnesium tube, carbon tube and other auxiliary parts into special pyrophyllite blocks to make synthetic blocks. The polycrystalline di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| collision energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com