Manufacturing method of copper-based brazing filler metal laser brazing cubic boron nitride grinding particles

A technology of cubic boron nitride and copper-based brazing filler metal, applied in manufacturing tools, welding media, welding equipment, etc., can solve the problems of high cost of CBN abrasive brazing, limited tool size, long production cycle, etc. The effect of low price, high energy density and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

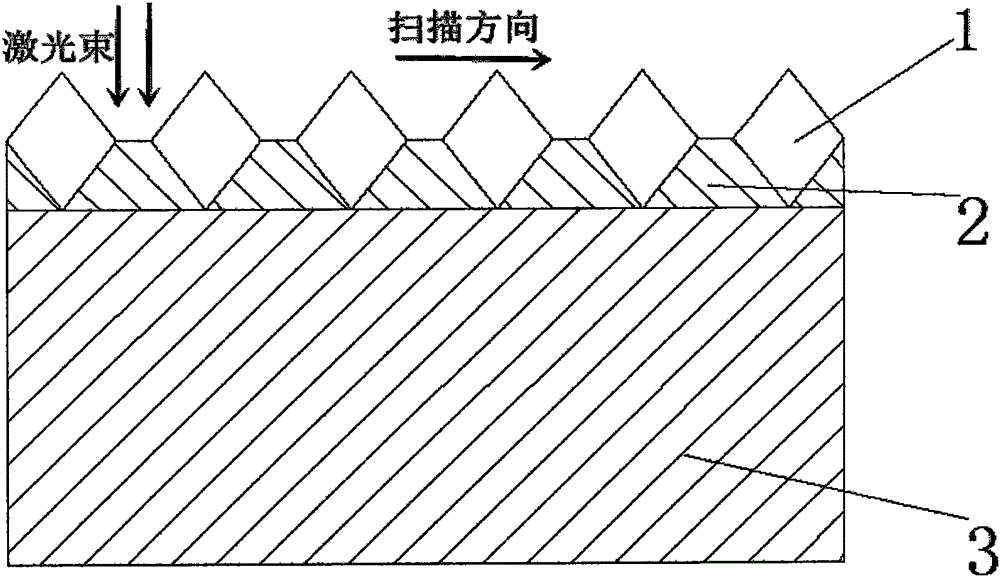

[0016] see figure 1 , the manufacture method of copper-based solder laser brazing cubic boron nitride abrasive grains, specifically comprising the following steps:

[0017] (1). Put the 45 steel substrate and CBN abrasive 1 into an organic solvent and use ultrasonic cleaning method to degrease and decontaminate. This process should be strictly required to prevent oil from remaining on the metal surface after being heated and destroying the impact of liquid solder on the steel. The wetting effect of the substrate and uncoated CBN abrasive grains affects the formation of the solder layer;

[0018] (2). Distribute the copper-based solder 2 (Cu78-81Ni5-6Sn3-5.5Ti10-12) on the 45 steel substrate 3, arrange the 40 / 50 mesh CBN abrasive grains 1 in an orderly manner on the copper-based solder 2 Above, make 45 steel matrix 3-copper-based solder 2-CBN abrasive grains 1 to be processed samples arranged in sequence from bottom to top;

[0019] (3). Put the sample to be added into the CO...

Embodiment 2

[0022] The analysis of the microstructure of the interface between CBN abrasive grains and copper-based solder shows that active Ti elements are obviously segregated to the surface of CBN abrasive grains; and B and N elements in CBN also show diffusion phenomenon into the solder layer. These phenomena indicate that A chemical reaction takes place at the interface. The CBN abrasive grains are covered by copper-based solder, showing good wettability, which indicates that a wetting reaction has occurred between the CBN abrasive grains and the solder. After deep corrosion treatment, the reaction products on the surface of abrasive grains were found to be prismatic through SEM observation, and the X-ray diffraction spectrum showed that the reaction products on the surface of abrasive grains were TiN, TiB and TiB 2 ;

[0023] Analysis of the structure of the interface between the 45 steel matrix and copper-based solder, SEM topography photos and element line scanning, it can be see...

Embodiment 3

[0026] The equipment used in this embodiment mainly includes: CO 2 Lasers, CNC machining machines, and gas protection devices.

[0027] CO 2 The laser power of the laser is 600-750W, the spot scanning speed is 15-35mm / min, and the laser spot area is 8-15mm 2 , the best process parameters of laser brazing gold CBN abrasive grains are: laser power 680W, scanning speed 24mm / min, laser spot area 12mm 2 .

[0028] The copper-based solder is a high-temperature copper-based active solder, and the composition of the copper-based solder is Cu: 78-81%, Ni: 5-6%, Sn: 3-5.5%, Ti: 10-12%; The particle size of coated CBN abrasive grains is 40 / 50 / 60 mesh.

[0029] The cubic boron nitride abrasive grains are laser brazed on the 45 steel substrate with copper-based brazing material, and a chemical metallurgical reaction occurs at the bonding interface to realize the high-strength connection between the CBN abrasive grains and the substrate; Surface segregation occurs, and TiN, TiB and TiB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com