High-temperature-resistant and wear-resistant rubber material for inner sheath of drilling power cable and preparation method for rubber material

A wear-resistant rubber and inner sheath technology, applied in rubber insulators, organic insulators, etc., can solve the problems of high temperature resistance and wear resistance that cannot meet the market demand, and achieve good coordination and synergy, wide application range, The effect of improving the flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

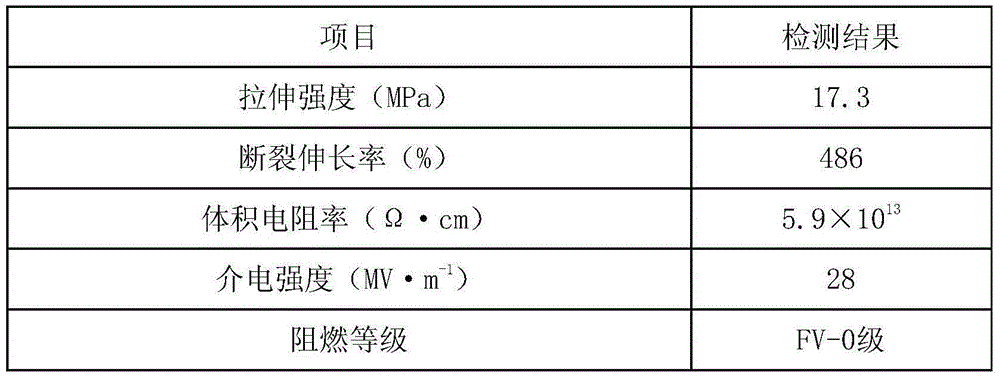

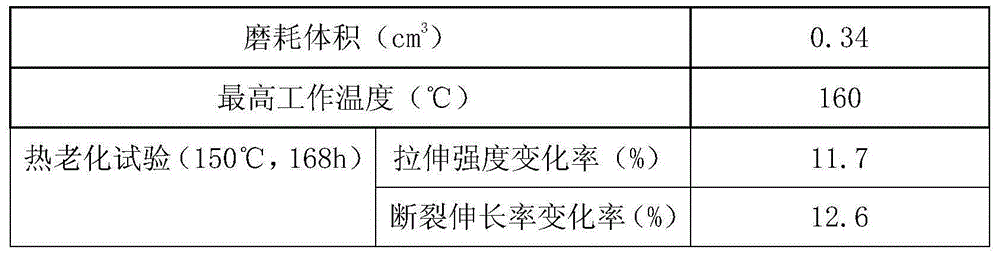

[0014] A high-temperature-resistant and wear-resistant rubber material for the inner sheath of a drilling power cord, which is made of the following raw materials by weight (kg): 36 acrylate rubber, 30 butylpyridine rubber, 22 thermoplastic polyurethane elastomer, and trinonyl trimellitate 16. Aramid pulp 12, gas carbon black 22, pine tar 7, coal tar pitch 10, C5 / C9 copolymerized petroleum resin 12, accelerator MBTS2.5, accelerator ZBPD2, tungsten disilicide 18, gray calcium powder 12, tellurium Powder 5, lanolin 6, pitch-based carbon fiber 12, antioxidant OD2.5, antioxidant NAPM1.5, antioxidant WSL1, diisopropyl peroxydicarbonate 5, N, N'-m-phenylene bismaleyl Imine 3.5, flame retardant particles 21;

[0015] The preparation method of the flame-retardant particles is as follows: a, take the raw materials of the following weight (kg): colemanite 27, brucite 23, boehmite 17, expanded graphite 12, basic sodium aluminum carbonate 8, basic Magnesium chloride 6, brominated bisphen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com