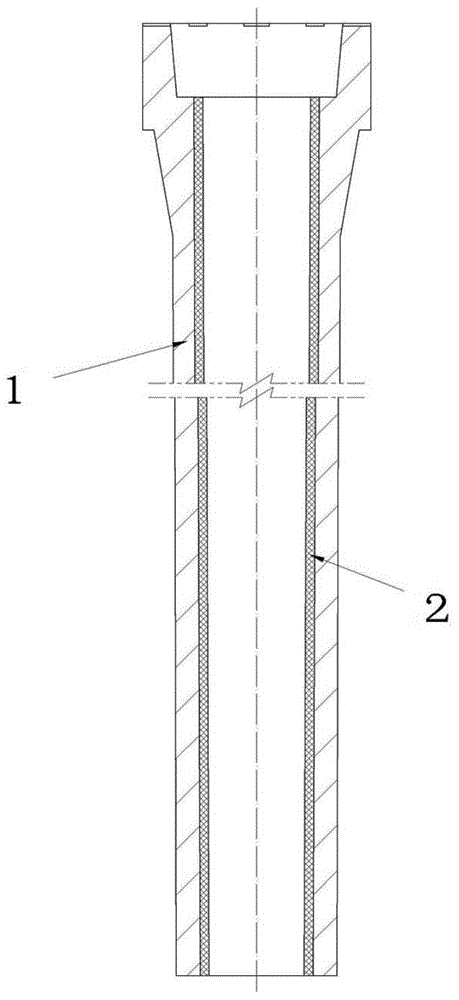

A reusable preheating-free shroud and its manufacturing method

A long shroud, no preheating technology, used in manufacturing tools, casting equipment, casting melt containers, etc., can solve problems such as thermal shock cracking, and achieve the effects of alleviating thermal stress, low thermal conductivity, and low thermal expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

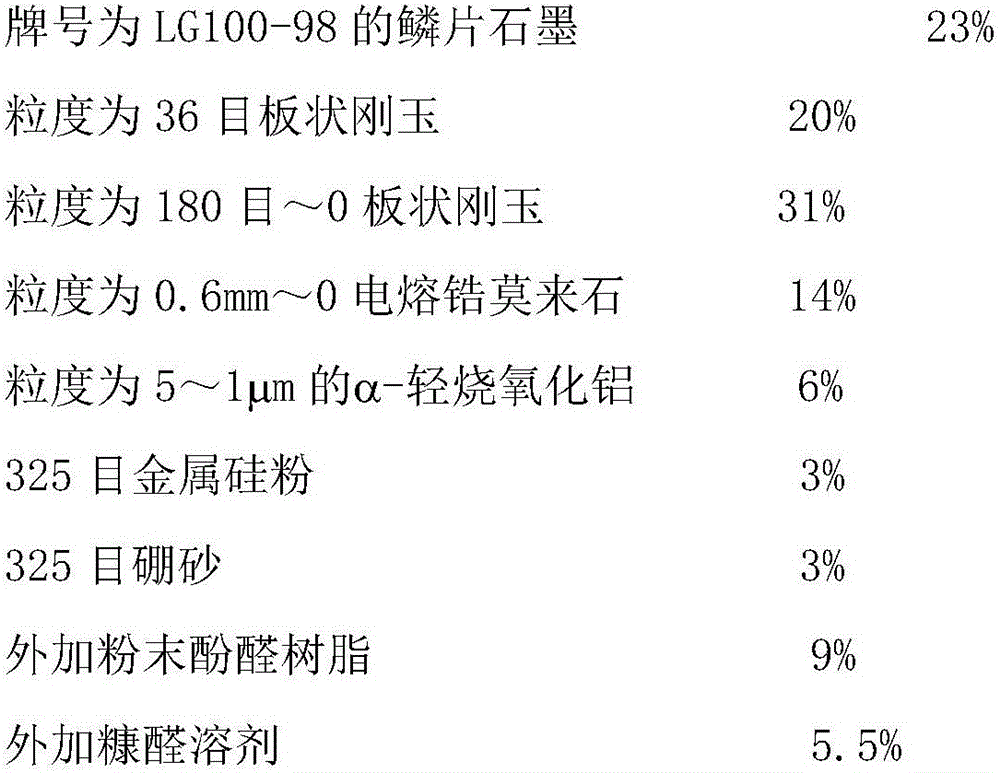

[0044] The prepared reusable outer layer body 1 of the preheating-free shroud is composed of ingredients according to mass percentage:

[0045]

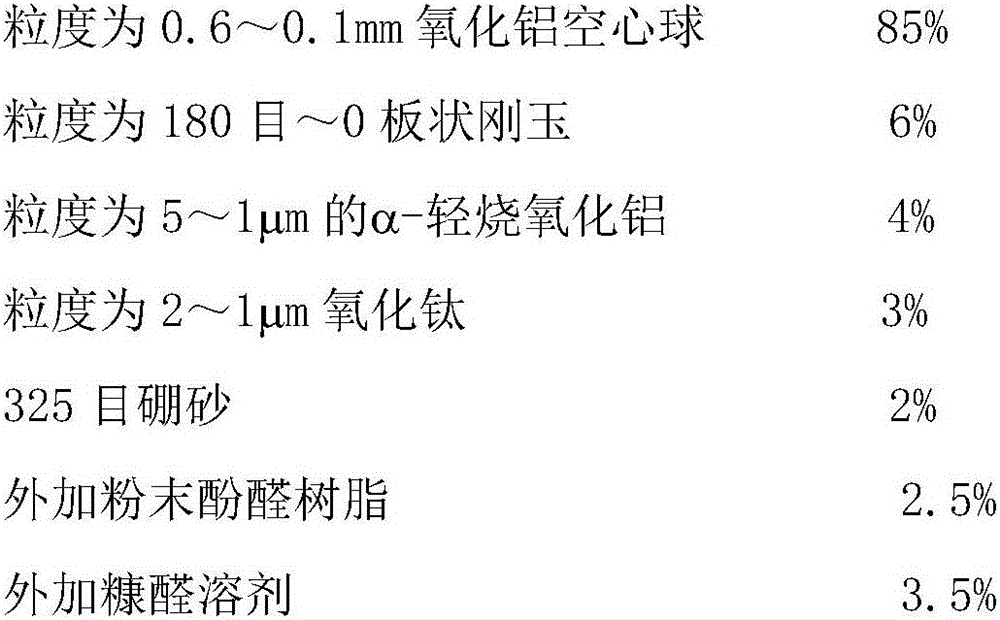

[0046] The prepared reusable lining 2 of the preheating-free shroud is composed of ingredients according to mass percentage:

[0047]

[0048] The manufacturing process of the above-mentioned reusable no-preheat shroud is as follows:

[0049] 1) Put the bulk raw materials weighed according to the proportion and the added powdered phenolic resin into the mixer for pre-mixing for 3 minutes, then add furfural solvent, after all the above components are mixed evenly, dry at 90°C for 1 Hours to a volatile content suitable for molding, as a body blank for use;

[0050] 2) Put the lining raw materials weighed according to the ratio and the added powdered phenolic resin into the mixer for pre-mixing for 3 minutes, then add furfural solvent, mix all the above components evenly, and dry at 90°C 1 hour to the volatile content suitable f...

Embodiment 2

[0057] The prepared reusable outer layer body of the preheating-free shroud is composed of ingredients according to mass percentage:

[0058]

[0059] The prepared reusable lining material of the no-preheating shroud is composed of ingredients according to mass percentage:

[0060]

[0061] In this embodiment, the manufacturing process of the reusable preheating-free shroud is the same as that in Embodiment 1.

Embodiment 3

[0063] The prepared reusable outer layer body of the preheating-free shroud is composed of ingredients according to mass percentage:

[0064]

[0065]

[0066] The prepared reusable lining of the preheating-free shroud is composed of ingredients according to mass percentage:

[0067]

[0068] In this embodiment, the manufacturing process of the reusable preheating-free shroud is the same as that in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com