Preparation method for high-temperature flue gas denitrification catalyst and product of high-temperature flue gas denitrification catalyst

A denitrification catalyst and high-temperature flue gas technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of easy cracking of green bodies, high energy consumption, and long drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

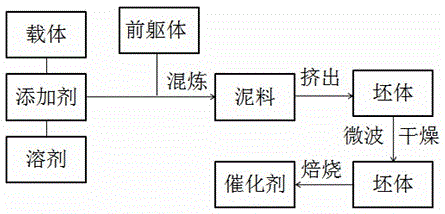

[0027] Such as figure 1 As shown, the present invention provides a method for preparing a high-temperature flue gas denitrification catalyst, comprising the following steps,

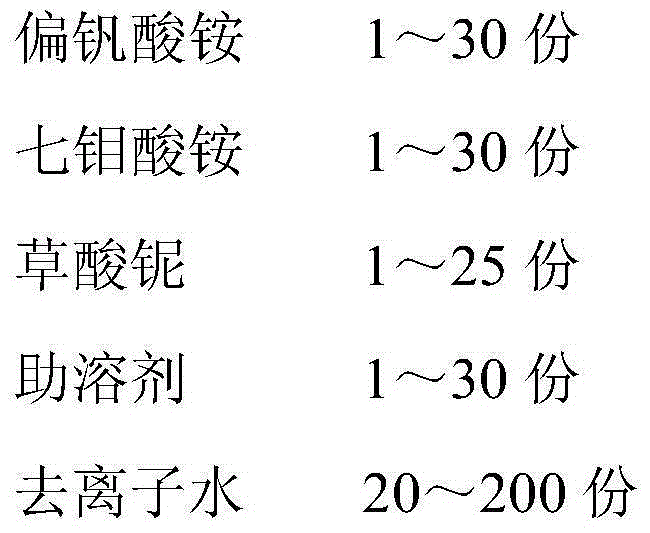

[0028] Step 1, precursor preparation, according to the following parts by weight:

[0029]

[0030] Mix, heat and stir to 80°C-100°C, keep warm for 6min-60min until all the solids are dissolved, and complete the preparation of the precursor;

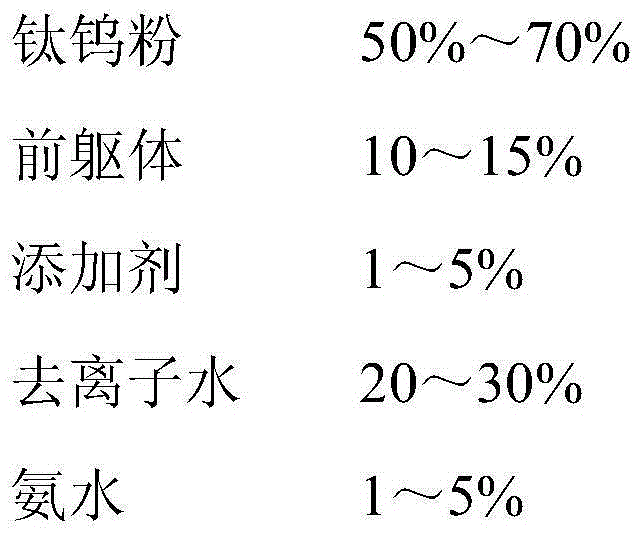

[0031] Step 2, catalyst preparation,

[0032] According to the following quality scores:

[0033]

[0034] Mixing is carried out to obtain uniformly mixed mud, in which titanium tungsten powder is used as a carrier, and the function is to support the active components in the catalyst, and the TiO in titanium tungsten powder 2 Anatase type, WO 3 The content is 2% to 8%, and the specific surface area is 85m 2 / g~95m 2 / g, and then through extrusion molding, drying to remove water, and roasting, the preparation of the catalyst is completed.

[0035] In th...

Embodiment 1

[0040] Step 1, weigh 13.4kg ammonium metavanadate, 15.6kg ammonium heptamolybdate, 6.6kg niobium oxalate, 15kg monoethanolamine, mix with 80kg deionized water, heat and stir to 90°C, keep warm for 30min until the solids are completely dissolved, and finally get V 2 o 5 , Nb 2 o 5 and MoO 3 Prebody I of

[0041]Step 2, weigh 600kg titanium-tungsten powder, 50kg glass fiber, 1.75kg carboxymethyl cellulose, 7.5kg polyethylene oxide, 7.5kg50% lactic acid, add 200kg deionized water, 60kg ammonia water and the precursor I obtained in step 1 Mixing, the time is 60 minutes, to obtain a uniformly mixed plastic mud with a certain degree; the plastic mud is pre-extruded through a screen filter to remove large particles of impurities, and the water and components are further mixed evenly; then vacuum extrusion Forming, the vacuum degree is -0.1Mpa, the extrusion speed is 1.5m / s, and a dense and uniform honeycomb catalyst body is obtained; the catalyst body is microwave-dried, the mic...

Embodiment 2

[0044] Step 1, weigh 13.4kg ammonium metavanadate, 15.6kg ammonium heptamolybdate, 6.6kg niobium oxalate, 15kg monoethanolamine, mix with 80kg deionized water, heat and stir to 90°C, keep warm for 30min until the solids are completely dissolved, and finally get V 2 o 5 , Nb 2 o 5 and MoO 3 Prebody II of

[0045] Step 2: Weigh 600kg of titanium-tungsten powder, 50kg of glass fiber, 1.75kg of carboxymethyl cellulose, 7.5kg of polyethylene oxide, 7.5kg of 50% lactic acid, add 200kg of deionized water, 60kg of ammonia water and the precursor II obtained in step 1. Mixing, the time is 60min, and the plastic mud is uniformly mixed and has a certain degree of plasticity; the plastic mud is pre-extruded through a screen filter, and then vacuum extruded, the vacuum degree is -0.1Mpa, and the extrusion speed is 1.5m / s to obtain a dense and uniform honeycomb catalyst body; the catalyst body is microwave-dried, the microwave treatment power is 200W, and the treatment time is 2h to r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com