Porous slow-release carbon source filler, preparation method and application thereof

A slow-release carbon source and raw material technology, applied in chemical instruments and methods, water treatment of special compounds, water/sludge/sewage treatment, etc., can solve problems such as in-depth research, environmental risks not mentioned, and effluent COD exceeding the standard , to achieve the effect of strengthening microbial denitrification, solving the low efficiency of denitrification, and having the effect of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

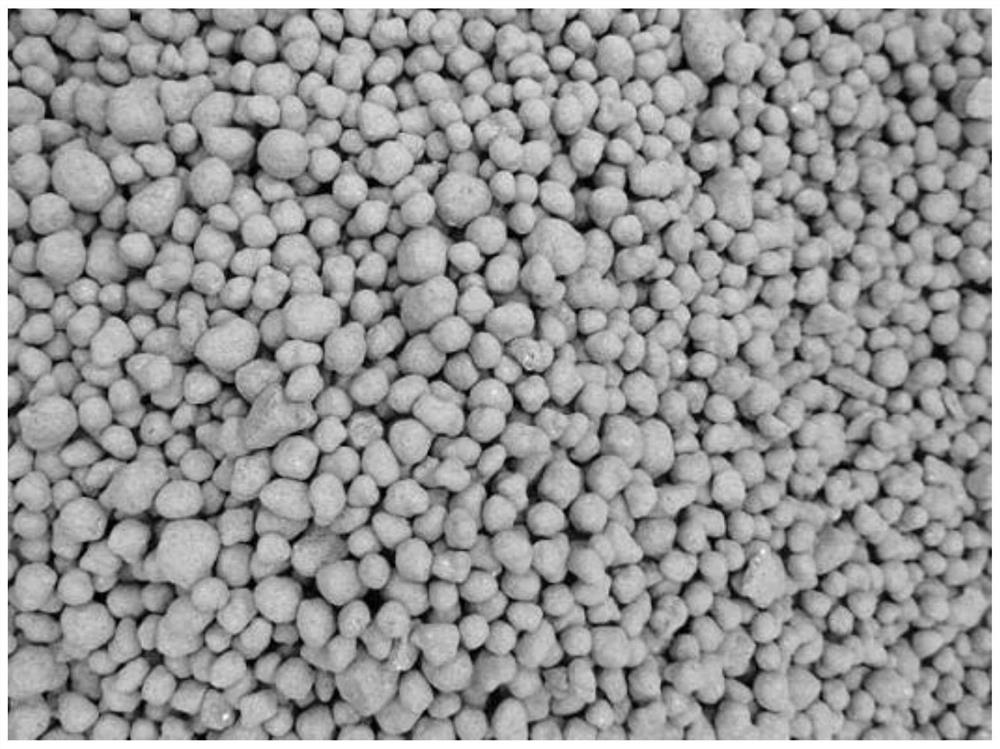

Image

Examples

Embodiment 1

[0033] According to wetland plants: calamus straw powder 5%; adsorbing mineral materials: zeolite powder 39%, calcium-based bentonite 15%, kaolin 6%; viscous material: ordinary Portland cement 34.95%; pore-forming agent: aluminum powder 0.05% Raw material ratio to prepare porous slow-release carbon source filler. The steps are:

[0034] (1) Take calamus stalks withered or harvested in artificial wetlands, wash and dry, pulverize with a pulverizer, pass through 80-100 mesh sieves to obtain wetland plant carbon source powder for future use. Zeolite powder, calcium-based bentonite, kaolin and ordinary Portland cement are all pulverized to 100-120 mesh for later use;

[0035] (2) Fully stir and mix the powder in step (1) in proportion, fully stir and mix evenly, add to the disc granulator several times in batches, set the granulator speed to 25r / min, and slowly Slowly add water to make the raw material roll into a spherical shape, with a particle size of about 8-9mm;

[0036] (...

Embodiment 2

[0038] According to wetland plants: calamus straw powder 2%, reed straw powder 3%; adsorption mineral materials: zeolite powder 25%, calcium-based bentonite 25%, kaolin 14.96%; viscous material: ordinary Portland cement 30%; pore-forming agent The invention relates to the preparation of porous slow-release carbon source filler with a raw material ratio of 0.04% of aluminum powder. The steps are:

[0039](1) Take calamus and reed straw withered or harvested in the artificial wetland, wash and dry, pulverize with a pulverizer, and pass through a sieve of 80-100 mesh to obtain wetland plant carbon source powder for future use. Zeolite powder, calcium-based bentonite, kaolin and ordinary Portland cement are all pulverized to 100-120 mesh for later use;

[0040] (2) Fully stir and mix the powder in step (1) according to the proportion, fully stir and mix evenly, add it to the disc granulator several times in batches, set the speed of the granulator to 20r / min, and slowly Slowly a...

Embodiment 3

[0043] According to wetland plants: calamus straw powder 3%; adsorption mineral materials: zeolite powder 40%, calcium-based bentonite 12.97%, diatomite 10%; viscous materials: ordinary Portland cement 17%, kaolin 17%; pore-forming agent The invention relates to the preparation of a porous slow-release carbon source filler with a raw material ratio of 0.03% of aluminum powder. The steps are:

[0044] (1) Take calamus stalks withered or harvested in artificial wetlands, wash and dry, pulverize with a pulverizer, pass through 80-100 mesh sieves to obtain wetland plant carbon source powder for future use. Zeolite powder, calcium-based bentonite, diatomite, ordinary Portland cement, and kaolin are all crushed to 100-120 mesh for later use;

[0045] (2) Fully stir and mix the powder in step (1) according to the proportion, add it to the disc granulator several times in batches, set the granulator speed to 20r / min, and slowly add water with the rotation to make the raw materials R...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com