Polyamino acid, preparation method thereof and drug loaded micelle

A polyamino acid and citrulline technology, applied in the field of polymers, can solve the problem of less research on polymer micelles, and achieve the effects of good biocompatibility, biodegradability, and good enzyme responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

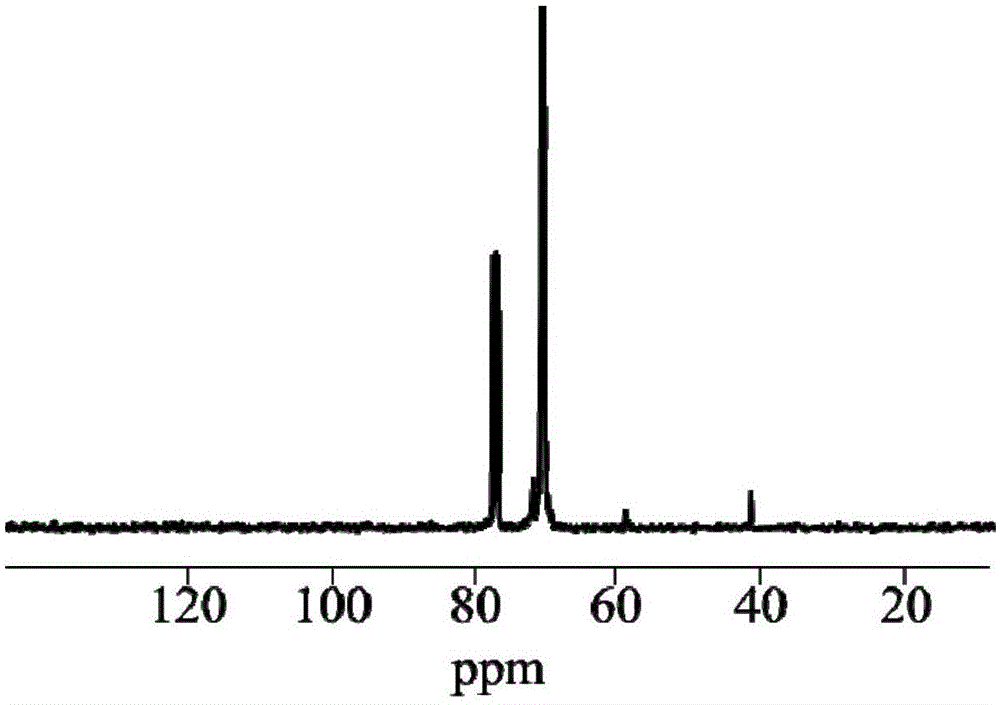

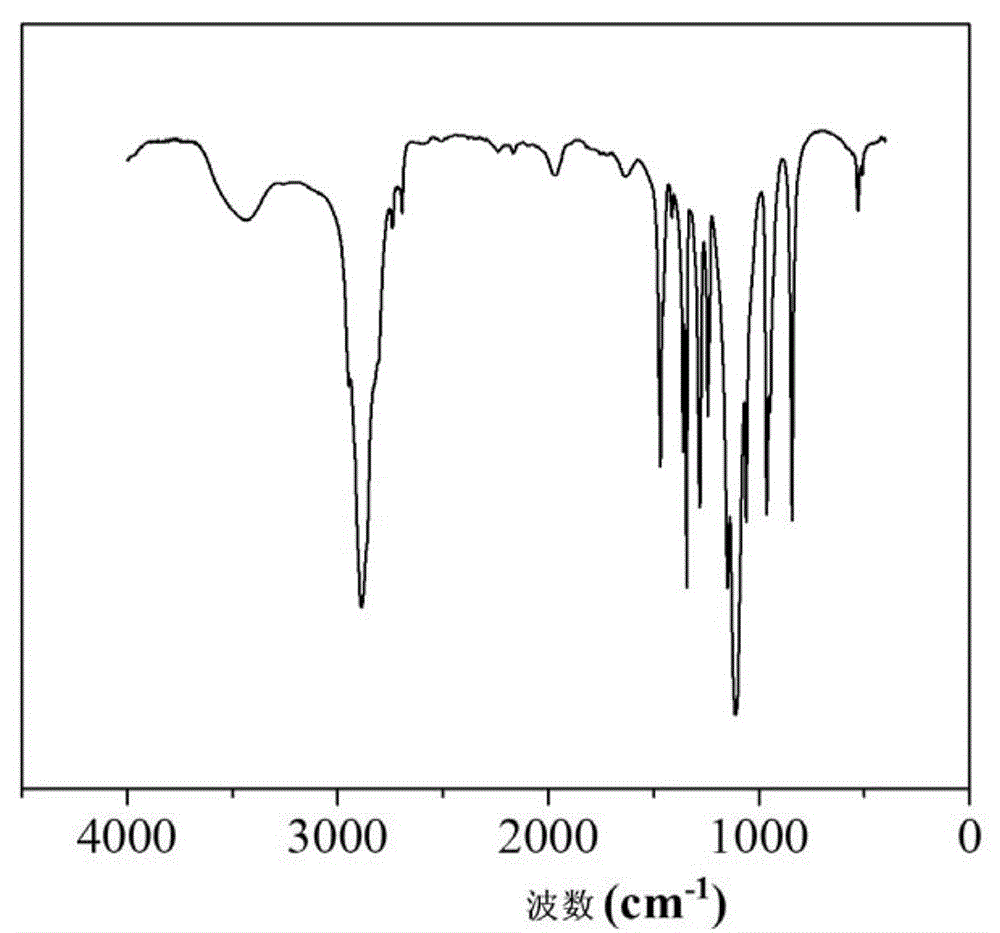

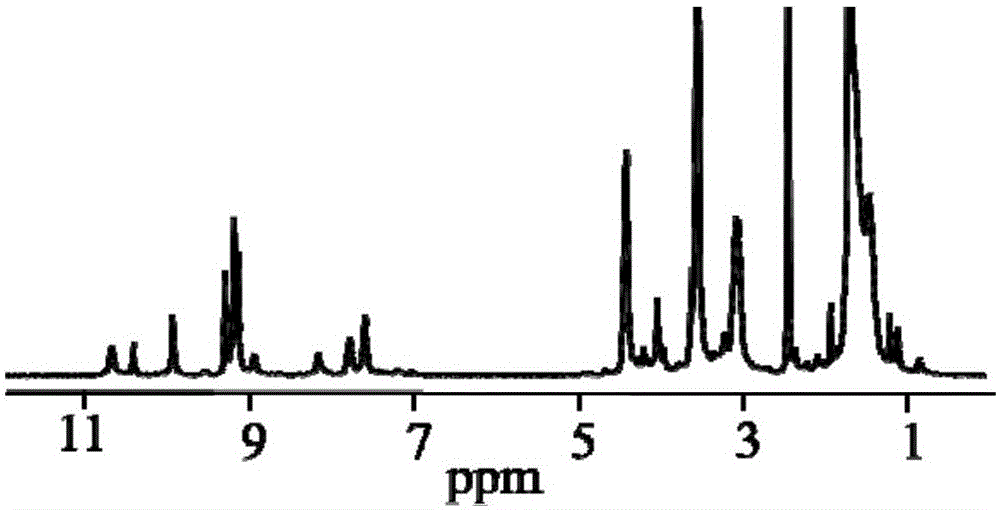

[0059] The present invention provides a method for preparing the polyamino acid described in the above technical solution, comprising:

[0060] In an organic solvent, react amino-terminated polyethylene glycol monomethyl ether, citrulline-N-internal carboxylic acid anhydride and valine-N-internal carboxylic anhydride to obtain polyamino acids; the amino-terminated polyethylene glycol Monomethyl ether has the structure shown in formula II:

[0061]

[0062] In formula II, 50≤n≤200;

[0063] The citrulline-N-internal carboxylic acid anhydride has a structure shown in formula III:

[0064]

[0065] The valine-N-internal carboxylic acid anhydride has a structure shown in formula IV:

[0066]

[0067] The invention reacts amino-terminated polyethylene glycol monomethyl ether, citrulline-N-internal carboxylic acid anhydride and valine-N-internal carboxylic acid anhydride in an organic solvent to obtain polyamino acid. In the embodiments of the present invention, the temp...

Embodiment 1

[0113] Put 20g of polyethylene glycol monomethyl ether with a number average molecular weight of 2000 into a dry reaction bottle, then vacuumize it at 120°C for 2 hours while stirring, put the reaction bottle in an oil bath, and when the temperature is 60°C 10g of anhydrous magnesium sulfate and 200mL of dichloromethane were added to the reaction flask respectively, and 5mL of triethylamine and 30mL of methanesulfonyl chloride were added to the reaction flask in an ice-water bath. React for 72 hours under the condition of agitator stirring. After the reaction, the obtained reaction product was washed five times with saturated sodium chloride solution, and then dried overnight by adding anhydrous magnesium sulfate; After drying under vacuum for 24h, an intermediate product was obtained;

[0114] Dissolve the intermediate product and ammonium chloride with the same quality as the intermediate product in ammonia water, the volume of ammonia water is 10 times the mass of the inter...

Embodiment 2

[0122] Put 20g of polyethylene glycol monomethyl ether with a number-average molecular weight of 4000 into a dry reaction bottle, then vacuumize it at 120°C for 2 hours while stirring, put the reaction bottle in an oil bath, and when the temperature is 60°C , add 10g of anhydrous magnesium sulfate, 200mL of dichloromethane dehydrated into the reaction flask respectively, add 2.5mL of triethylamine and 15mL of methanesulfonyl chloride into the reaction flask under the condition of ice-water bath, at 25°C 1. Reaction 72h under stirring bar stirring condition, after the reaction finishes, the reaction product obtained is washed five times with saturated sodium chloride solution and then dried overnight by adding anhydrous magnesium sulfate; the product after drying is settled with anhydrous ether, and the After vacuum drying at ℃ for 24h, an intermediate product was obtained;

[0123] Dissolve the intermediate product and ammonium chloride with the same quality as the intermediat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com