Method and application of low-temperature solid-phase synthesis of sodium arsenic alunite solid solution

A technology for arsenic alumite and solid-phase synthesis, which is used in the treatment of arsenic-containing waste residues, low-temperature solid-phase synthesis of arsenic alumite solid solution, and the preparation of sulfate minerals, which can solve the problems of poor stability of arsenic compounds, environmental pollution, etc. problem, to achieve the effect of good long-term stability, low economic cost, safe and reliable storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

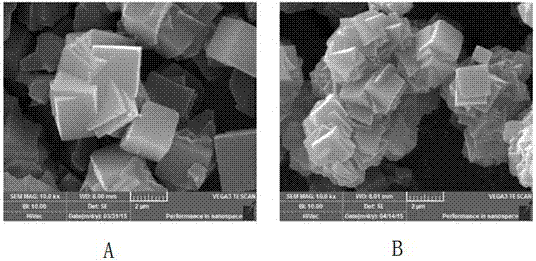

[0016] Example 1: At room temperature, mix 10g of aluminum sulfate powder and 1g of sodium sulfate powder directly without grinding, add 1g of sodium arsenate, mix again without grinding; put the mixture in a reaction kettle, and react at 100°C for 72h After the reaction, the product was naturally cooled, washed with 500 mL of distilled water, and finally dried at 100°C for 24 hours to obtain arsenite with high crystallinity.

[0017] Performance test: continuous leaching for 4 months, arsenic leaching concentration 2.5mg / L.

Embodiment 2

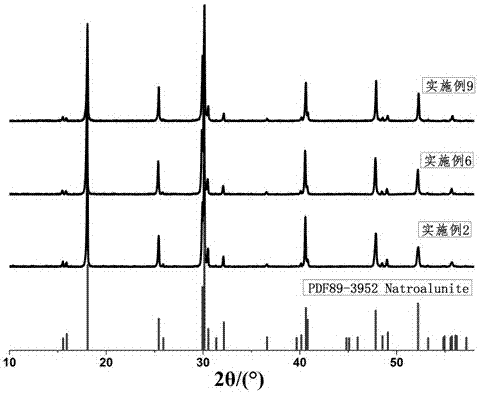

[0018] Example 2: At room temperature, mix and grind 70g of aluminum sulfate powder and 10g of sodium sulfate powder for 10 minutes, add 14g of sodium arsenate, mix and grind again for 20 minutes, put the mixture in a reaction kettle, and react at 200°C for 5.5 hours After the reaction, the product was naturally cooled, washed with 1000 mL of distilled water, and finally dried at 80° C. for 24 hours to obtain arsenite with high crystallinity.

[0019] Performance test: continuous leaching for 4 months, arsenic leaching concentration 2.0mg / L.

Embodiment 3

[0020] Example 3: At room temperature, 160 g of aluminum sulfate powder and 25 g of sodium sulfate powder were mixed and ground for 20 minutes, 90 g of sodium arsenate was added, and after mixing and grinding for 50 minutes again, the mixture was placed in a reaction kettle and heated at 220° C. After the reaction for 2.5 h, the product was naturally cooled, washed with 800 mL of distilled water, and finally dried at 90°C for 24 hours to obtain arsenite with high crystallinity.

[0021] Performance test: continuous leaching for 4 months, arsenic leaching concentration 1.0mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com