Preparation method of phosphorus-containing flame-retardant organic-inorganic hybrid silsesquioxane and epoxy resin hybrid material

A technology of silsesquioxane and epoxy resin, which is applied in the field of preparation of phosphorus-containing flame-retardant organic-inorganic hybrid silsesquioxane and epoxy resin hybrid materials, and can solve the preparation steps of flame-retardant epoxy resin Complicated, difficult, insufficient flame retardant and fire-resistant properties of epoxy resin, etc., to achieve excellent flame retardant and fire resistance, increase stability, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

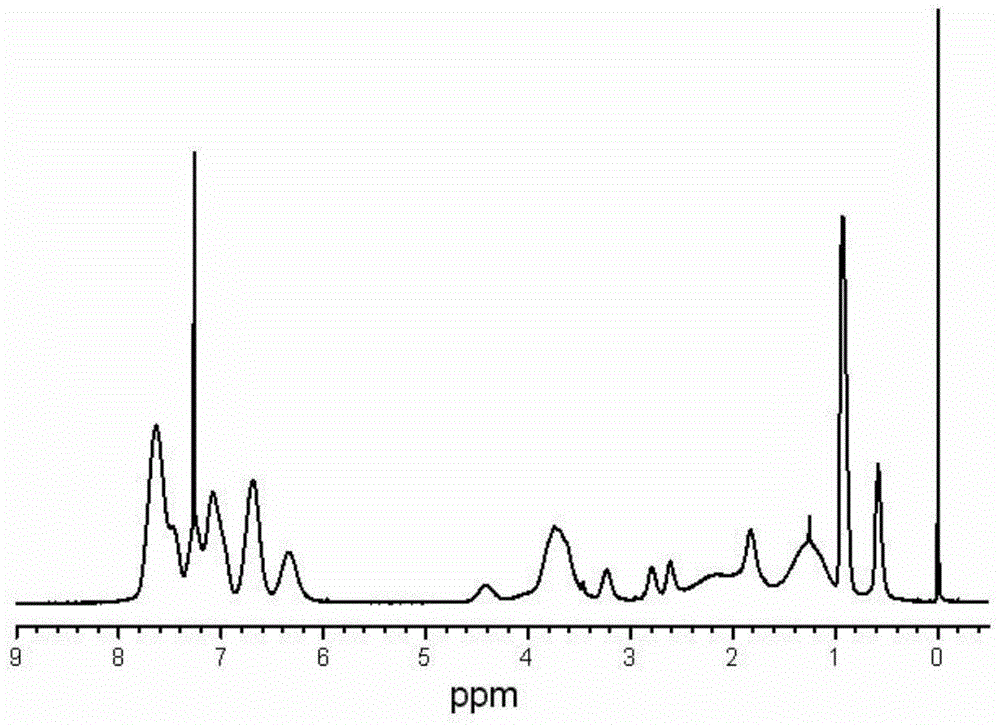

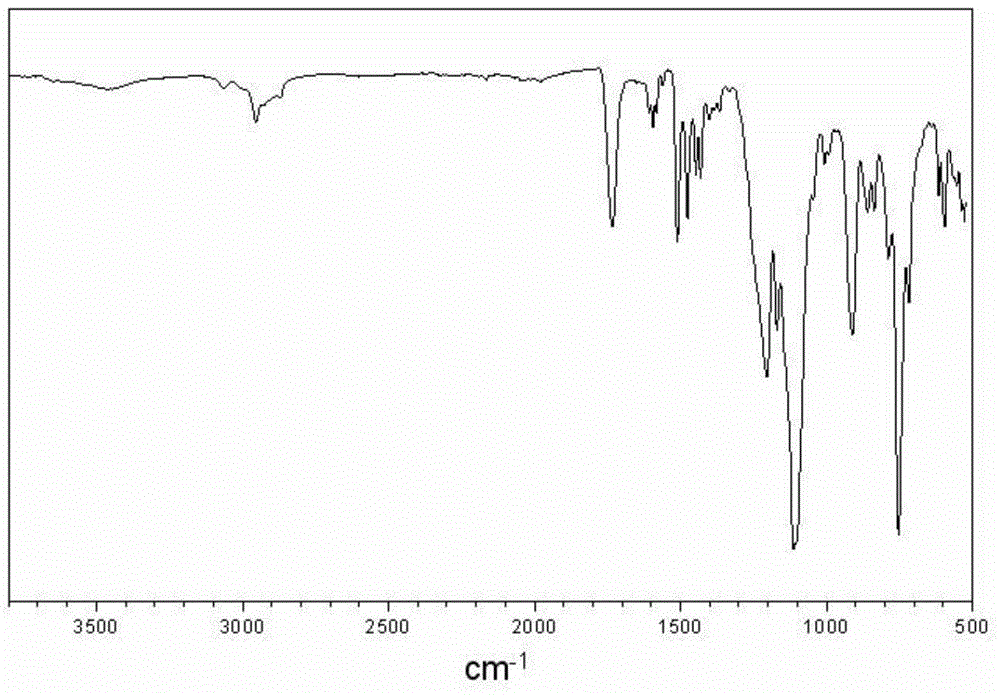

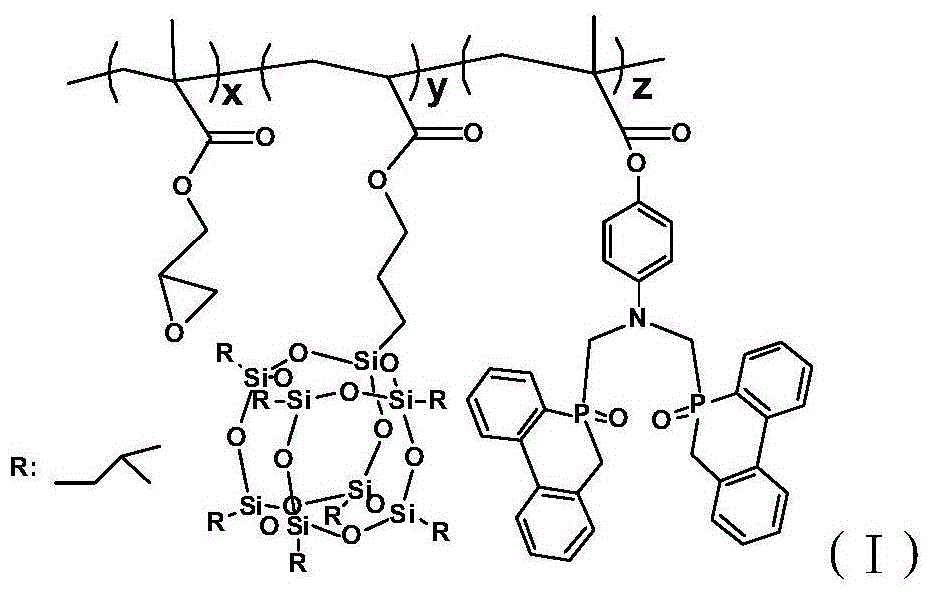

[0027] 1) Preparation of phosphorus-containing POSS-based compounds: In a 1000mL reaction vessel, 26g of glycidyl methacrylate, 132g of phosphorus-containing monomers, 41g of AiBuPOSS (acryloxypropyl heptaisobutyl cage silsesquioxane alkane) and 1g of initiator azobisisobutyronitrile (AIBN) were dissolved in 500mL of tetrahydrofuran, stirred and reacted for 24h at 65°C under the protection of nitrogen; after the reaction, the reaction solution was purified by precipitation with methanol, and the dried product was a yellow powder. It is a phosphorus-containing POSS-based compound, and the molecular structure of the phosphorus-containing POSS-based compound is shown in formula (I):

[0028]

[0029] Wherein x:y:z=1:1:8, relative molecular weight is 27824;

[0030] The molecular structural formula of the phosphorus-containing monomer is shown in formula (II), and its preparation method refers to Chinese patent CN104262398A;

[0031]

[0032] 2) Preparation of phosphorus-co...

Embodiment 2

[0034] 1) Preparation of phosphorus-containing POSS-based compounds: In a 1000mL reaction vessel, 26g of glycidyl methacrylate, 132g of phosphorus-containing monomer, 46g of AiBuPOSS and 1g of initiator AIBN were dissolved in 500mL of tetrahydrofuran. Under protection, the reaction was stirred for 24 hours; after the reaction, the reaction solution was purified by precipitation with methanol, and the product after drying was a yellow powder, which was a phosphorus-containing POSS-based compound. The molecular structure of the phosphorus-containing POSS-based compound was shown in formula (I):

[0035]

[0036] Wherein x:y:z=1:1:7, relative molecular weight is 34638;

[0037] Described phosphorus-containing monomer is with embodiment 1;

[0038]2) Preparation of phosphorus-containing flame-retardant organic-inorganic hybrid silsesquioxane and epoxy resin hybrid material: 100g of epoxy resin (E-51) and 10g of phosphorus-containing POSS-based compound obtained in step 1) in A...

Embodiment 3

[0040] 1) Preparation of phosphorus-containing POSS-based compounds: In a 1000mL reaction vessel, 26g of glycidyl methacrylate, 127g of phosphorus-containing monomer, 46g of AiBuPOSS and 1g of initiator AIBN were dissolved in 500mL of tetrahydrofuran. Under protection, the reaction was stirred for 24 hours; after the reaction, the reaction solution was purified by precipitation with methanol, and the product after drying was a yellow powder, which was a phosphorus-containing POSS-based compound. The molecular structure of the phosphorus-containing POSS-based compound was shown in formula (I):

[0041]

[0042] Wherein x:y:z=1:1:6, relative molecular weight is 37824;

[0043] Described phosphorus-containing monomer is with embodiment 1;

[0044] 2) Preparation of phosphorus-containing flame-retardant organic-inorganic hybrid silsesquioxane and epoxy resin hybrid material: 100g of epoxy resin (E-51) and 15g of phosphorus-containing POSS-based compound obtained in step 1) in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com