Method for preparing I crystal form of spherical clopidogrel hydrogen sulfate

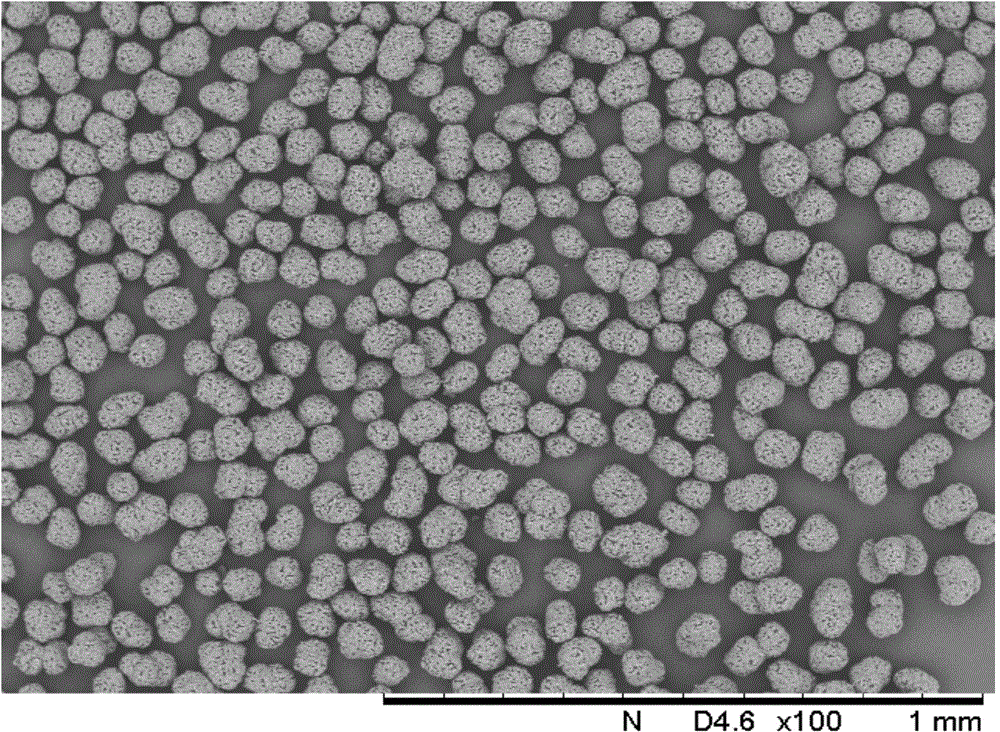

A technology of clopidogrel hydrogen sulfate and clopidogrel free base, applied in organic chemistry methods, organic chemistry and other directions, can solve problems such as affecting product quality, stricter residue requirements, reducing product bulk density, etc., to reduce solvent residues Risk and cost recovery, the effect of achieving industrialized continuous production, high fluidity and bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Take 760g of clopidogrel bisulfate (purity greater than 99.0%) and disperse it in a mixture of 10L of dichloromethane and 5L of water, and add solid sodium bicarbonate until the pH of the aqueous phase>7. Stand still for liquid separation, take the organic phase and wash with water (1L×2), and remove water with anhydrous magnesium sulfate until the solution is clear.

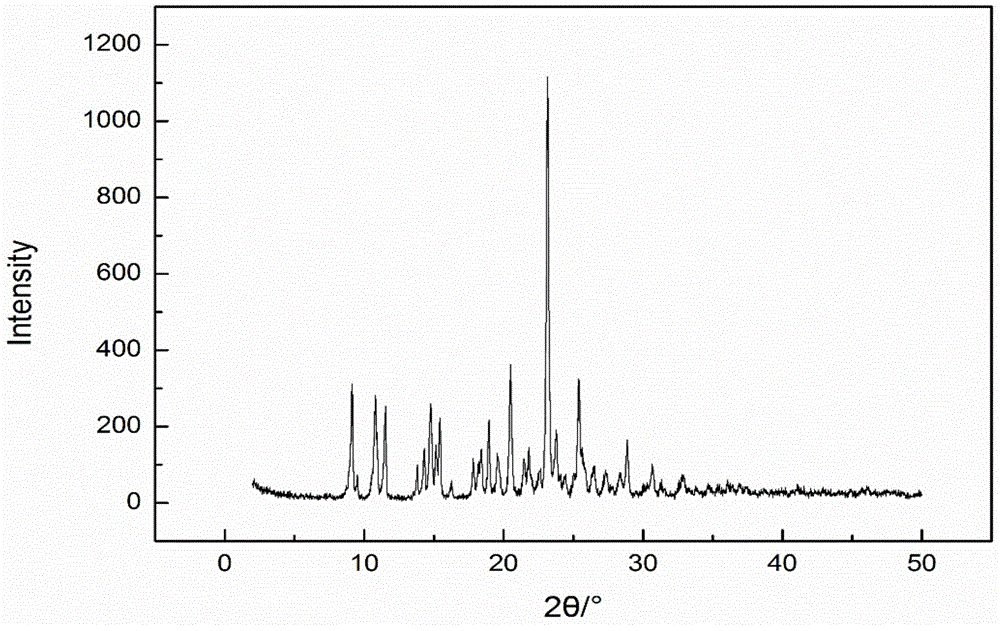

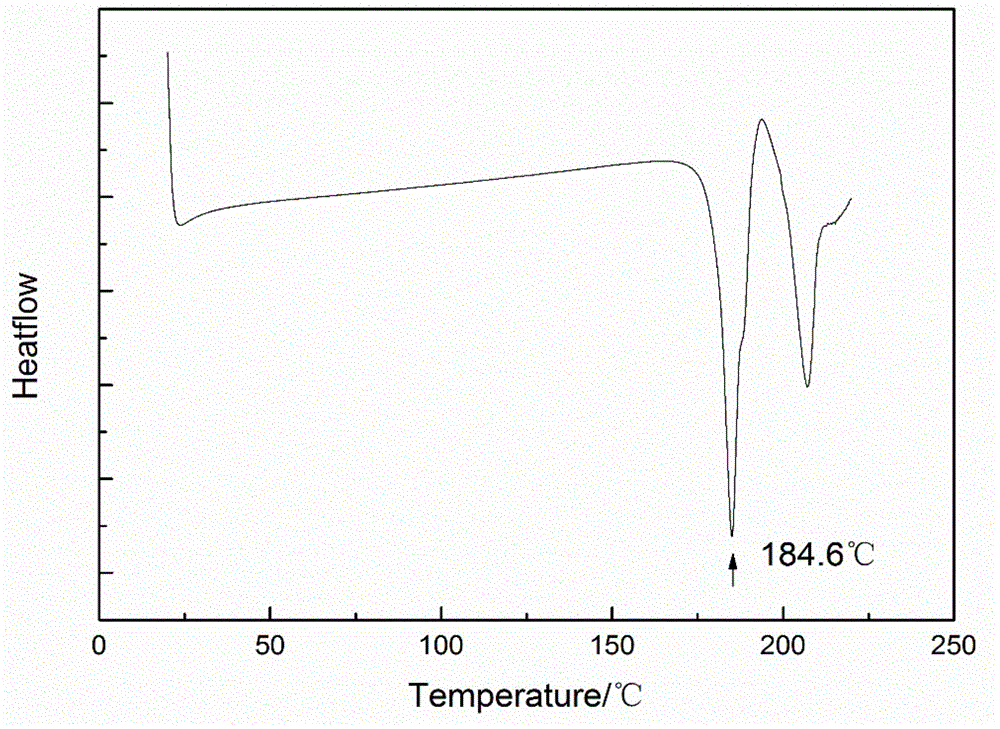

[0054] The organic phase was filtered and vacuum rotary evaporated until the quality did not change, the residue was dissolved in 10.5 L of 2-butanol, and the solution was kept at 25°C. Disperse 100ml of concentrated sulfuric acid (181g) in 2.5L of 2-butanol and add it to the system within 10 minutes, and disperse 10g of Form I seed crystals in 1L of 2-butanol and pour them in together. Keep warm at 25°C for 2.5h, lower the temperature to 15°C and keep warm for 3h, filter with suction, wash the filter cake with ethyl acetate, and dry in vacuum at 40°C for 1.0h to obtain 610g of product (2-butanol residue ...

Embodiment 2

[0057] Take 1000 g of clopidogrel camphorsulfonate (purity greater than 99.0%) and disperse it in a mixture of 10 L of dichloromethane and 5 L of water, and add solid sodium bicarbonate until the pH of the aqueous phase>7. Stand still for liquid separation, take the organic phase and wash with water (1L×2), and remove water with anhydrous magnesium sulfate until the solution is clear.

[0058] The organic phase was filtered and vacuum rotary evaporated until the quality did not change, the residue was dissolved in 10.5 L of 2-butanol, and the solution was kept at 25°C. Disperse 100ml of concentrated sulfuric acid (181g) in 2.5L of 2-butanol and add it to the system within 10 minutes, and disperse 12g of Form I seed crystals in 1L of 2-butanol and pour them in together. Keep warm at 25°C for 2.5h, cool down to 15°C and keep warm for 3h, filter with suction, wash the filter cake with ethyl acetate, and vacuum dry at 40°C for 1.0h to obtain 605g of product (2-butanol residue <0.2...

Embodiment 3

[0063] Using the same feed ratio and process operation as in Example 1, and using different sulfuric acid addition times, the relationship between the sulfuric acid addition time and the product form and crystal form was studied.

[0064] Numbering

time (min)

shape

crystal form

1

15

spherical

Type I

0.77

2

20

spherical

Type I

0.76

3

30

spherical

Type I

0.75

4

40

spherical

Type I

0.75

5

80

Spherical

Type I / II mixed crystal

0.68

6

120

Spherical

Type I / II mixed crystal

0.65

7

180

Spherical

Type I / II mixed crystal

0.58

[0065] It can be seen that under the premise that other process conditions remain unchanged, there is a certain relationship between the time of adding sulfuric acid and the product form and crystal form. Specifically, as the addition time of sulfuric acid incr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com