A kind of composite carrier type catalyst for producing low-carbon alcohol from syngas and preparation method thereof

A technology of composite carrier and catalyst, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problem of low alcohol selectivity of total alcohol, and improve the selectivity of total alcohol and improve the dispersion performance, enhance the effect of synergistic catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

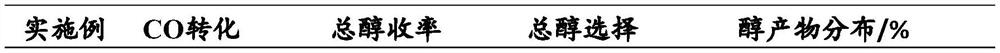

Examples

preparation example Construction

[0033] The present invention also provides a method for preparing a composite carrier-type catalyst for producing low-carbon alcohols from synthesis gas. The first embodiment of the present invention includes the following steps:

[0034] Step 1, adding ethyl orthosilicate to the ethanol solution to form a mixed solution a with a weight content of 8-15% ethyl orthosilicate, impregnating the mixed solution a into carbon nanotubes in equal volumes, and dispersing Drying and roasting are carried out to obtain a composite carrier.

[0035] Specifically, due to equal-volume impregnation, the volume of the impregnating solution (mixed solution a) can be determined according to the liquid absorption and weight of the selected carbon nanotubes, for example, 50 g of carbon nanotubes and 30 mL of mixed solution a can be selected. Tetraethyl silicate is used as a silicon source to modify the surface of the carbon nanotube channels, and if the addition amount is too high, the silica will ...

Embodiment 1

[0051] (1) Preparation of composite carrier

[0052] Prepare 30 mL of ethanol solution a containing 10% tetraethyl orthosilicate, add solution a dropwise to 50 g of carbon nanotubes, stir evenly after the addition is complete, and after ultrasonic treatment for 2 to 4 hours, dry and roast under a nitrogen atmosphere to obtain a composite carrier.

[0053] (2) Catalyst preparation

[0054] Copper nitrate, cobalt nitrate, rhodium nitrate and composite carrier are weighed according to the ratio of copper: cobalt: rhodium=15:10:1, copper: composite carrier=1:5 according to the mass ratio of each component of the catalyst. Dissolve with cobalt nitrate to form a uniform mixed solution b, add the mixed solution b dropwise to the weighed composite carrier for impregnation, perform ultrasonic treatment for 2 to 4 hours after the dropwise addition, and then dry and roast under nitrogen atmosphere to obtain the catalyst Precursor A: adding catalyst precursor A to deionized water to for...

Embodiment 2

[0058] (1) The preparation of the composite carrier is the same as in Example 1.

[0059] (2) Catalyst preparation, the mass ratio of each component of the catalyst is copper:cobalt:rhodium=20:10:1, copper:composite support=1:5.5, and other conditions are the same as in Example 1.

[0060] (3) Catalyst evaluation, with embodiment 1 evaluation condition, evaluation result sees table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com