porous graphene/mno 2 Coaxial nanowire with tube centerline structure and its preparation method and application

A technology of porous graphene and nanowires, applied in the field of nanomaterials and electrochemistry, to achieve the effects of improving stability, shortening ion diffusion distance, and uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Porous graphene / MnO 2 A method for preparing a coaxial nanowire material with a centerline structure in a tube, comprising the steps of:

[0035] 1) Dissolve 1mmol potassium permanganate powder in 70mL deionized water, add 2mmol ammonium fluoride, stir at room temperature for 10-20 minutes, and stir well;

[0036] 2) Add 2ml graphene dispersion in proportion to the solution obtained in step 1), and stir for 10-15 minutes;

[0037] 3) Transfer the solution obtained in step 2) into a 100mL reactor, react at 180°C for 3 hours, take out the reactor, and cool to room temperature naturally;

[0038] 4) The product obtained in step 3) is soaked and reduced in 5mmol / L hydrazine hydrate for 2h and then taken out;

[0039] 5) Wash the product obtained in step 4) repeatedly with absolute ethanol, and dry to obtain porous graphene / MnO 2 Tube centerline structure coaxial nanowires.

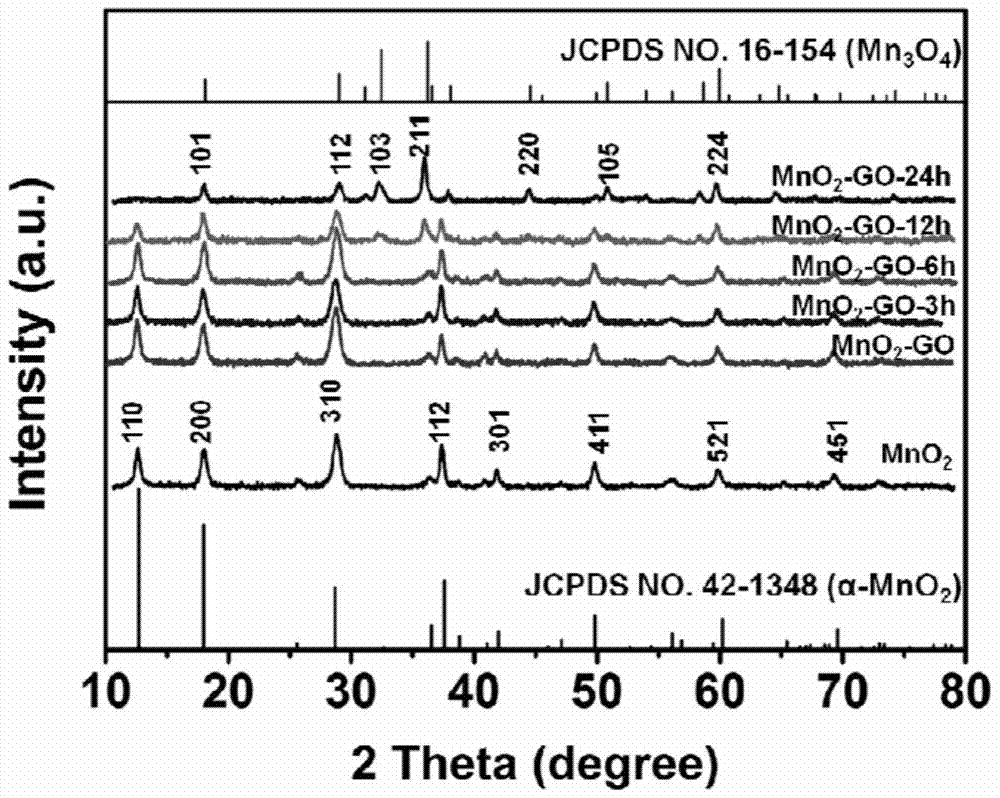

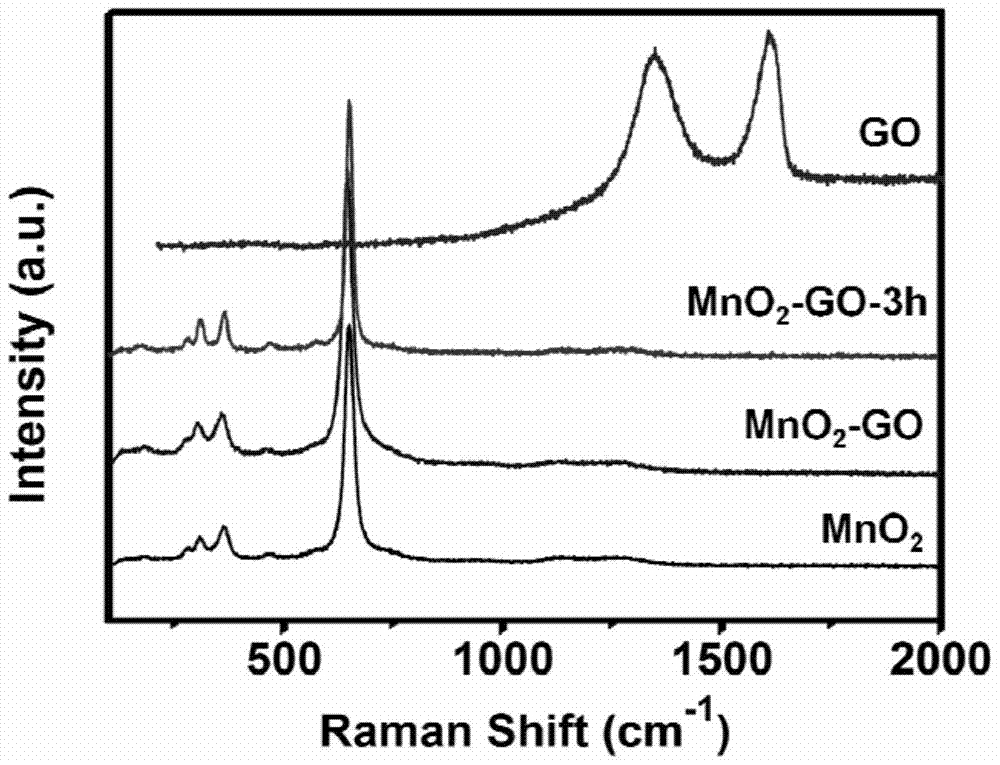

[0040] The product porous graphene / MnO of this experiment invention 2 Take the coaxial nanowire...

Embodiment 2

[0046] 1) Dissolve 2mmol potassium permanganate powder in deionized water, add 2mmol ammonium fluoride, stir at room temperature for 10-20 minutes, and stir evenly;

[0047] 2) Add 2ml graphene dispersion in proportion to the solution obtained in step 1), and stir for 10-15 minutes;

[0048] 3) Transfer the solution obtained in step 2) into a 100mL reaction kettle, react at 180°C for 6 hours, take out the reaction kettle, and naturally cool to room temperature;

[0049] 4) The product obtained in step 3) is soaked and reduced in 10mmol / L hydrazine hydrate for 2h and then taken out;

[0050] 5) Wash the product obtained in step 4) repeatedly with absolute ethanol, and dry to obtain porous graphene / MnO 2 Tube centerline structure coaxial nanowires.

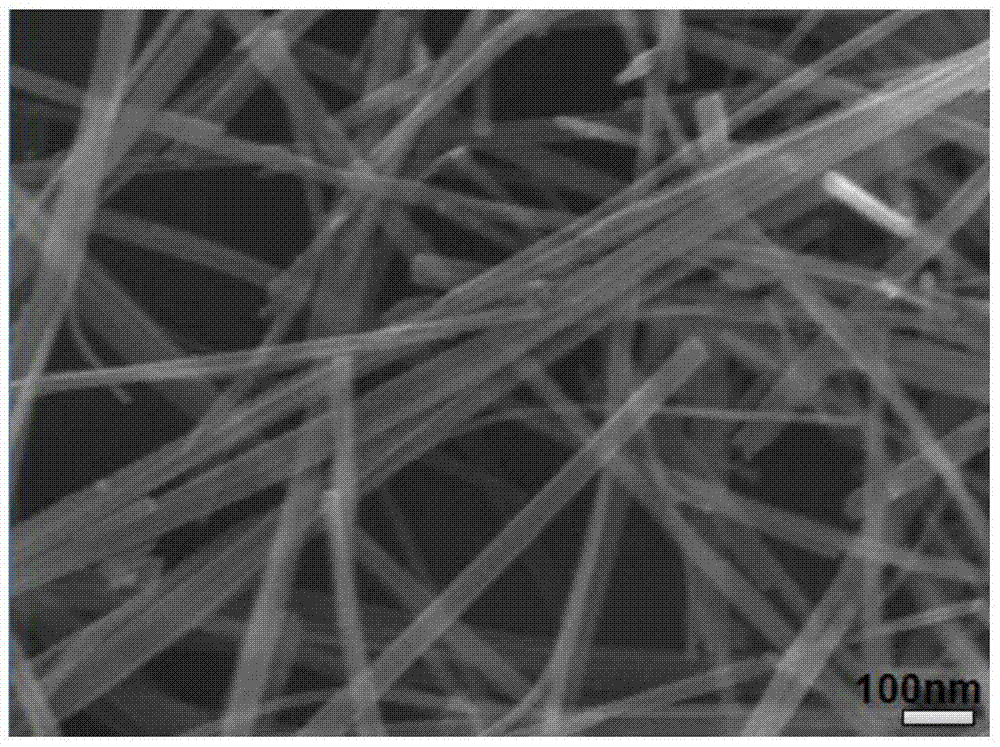

[0051] The coaxial nodal nanomaterial product of the present invention is assembled from porous graphene sheets and manganese dioxide nanowires, with a length of 10-40 microns and a diameter of 40-160 nanometers, wherein MnO 2 Th...

Embodiment 3

[0054] 1) Dissolve 2mmol potassium permanganate powder in deionized water, add 2mmol ammonium fluoride, stir at room temperature for 10-20 minutes, and stir evenly;

[0055] 2) Add 2ml graphene dispersion in proportion to the solution obtained in step 1), and stir for 10-15 minutes;

[0056] 3) Transfer the solution obtained in step 2) into a 100mL reaction kettle, react at 180°C for 6 hours, take out the reaction kettle, and naturally cool to room temperature;

[0057] 4) The product obtained in step 3) is soaked and reduced in 10mmol / L hydrazine hydrate for 2h and then taken out;

[0058] 5) Wash the product obtained in step 4) repeatedly with absolute ethanol, and dry to obtain porous graphene / MnO 2 Tube centerline structure coaxial nanowires.

[0059] The coaxial nodal nanomaterial product of the present invention is assembled from porous graphene sheets and manganese dioxide nanowires, with a length of 10-40 microns and a diameter of 40-160 nanometers, wherein MnO 2 Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com