Multi-scale-structure SiC/C porous composite ceramic and preparation method thereof

A composite ceramic, multi-scale technology, applied in ceramic products, other household appliances, household appliances, etc., can solve the problem of reducing the specific surface area of porous SiC ceramics, and achieve the effect of avoiding the reduction of specific surface area, high specific surface area, and saving operation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Concrete preparation process is as follows:

[0030] Step 1: Select a density of 0.2 to 0.6g / cm 3 The polyacrylonitrile-based carbon fiber felt is used as the carbon fiber skeleton; the selected carbon fiber skeleton is put into a hydrothermal reaction kettle, and the sucrose solution is used as the carbon source precursor. Take out the carbon skeleton of the polyacrylonitrile-based carbon fiber felt after one hour, and dry it; wherein, the concentration of the sucrose solution is controlled at 100g-500g / L, and the ratio of the polyacrylonitrile-based carbon fiber felt to the sucrose solution is (1-5)g: (30 ~50) mL.

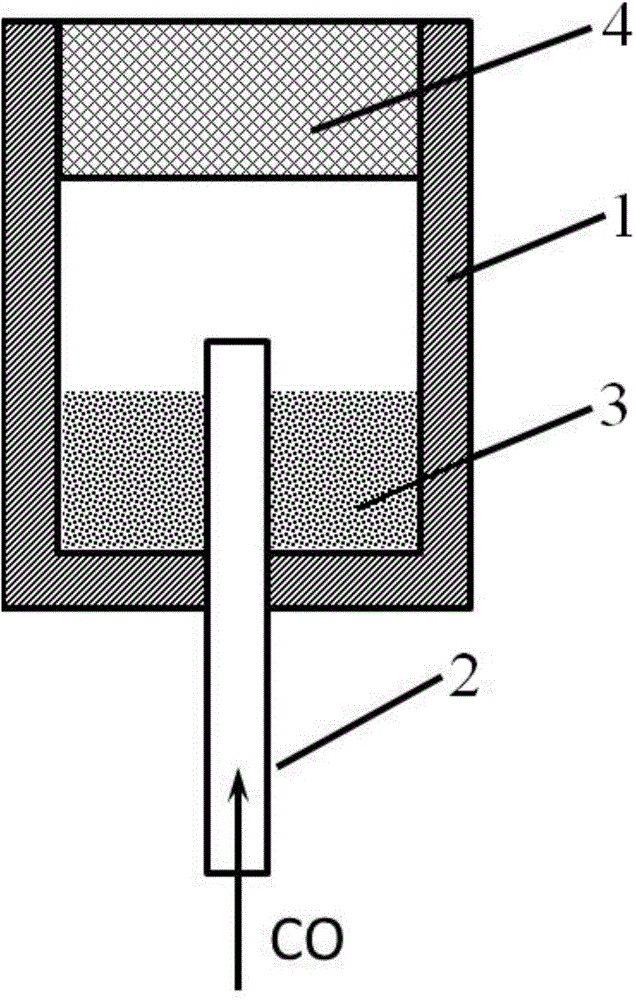

[0031] Step 2: Combine Si with SiO 2 The mixed powder 3, the carbon fiber skeleton 4 dried in step 1 are added in the graphite crucible 1, and the bottom of the graphite crucible 1 has a vent pipe 2 for passing gas into the crucible and extending into the inside of the crucible, Si and SiO 2 The height of the mixed powder is lower than the height of the...

Embodiment 1

[0035] Step 1: Choose a density of 0.2g / cm 3 The polyacrylonitrile-based carbon fiber felt is used as the carbon fiber skeleton;

[0036] Step 2: Put the carbon fiber skeleton selected in step 1 into a hydrothermal reaction kettle, then add a sucrose solution as a carbon source precursor, deposit the carbon fiber skeleton for 2 hours at a reaction temperature of 180°C, and then dry it; , the concentration of sucrose solution is 100g / L, the ratio of polyacrylonitrile-based carbon fiber felt to sucrose solution is 1g:30mL.

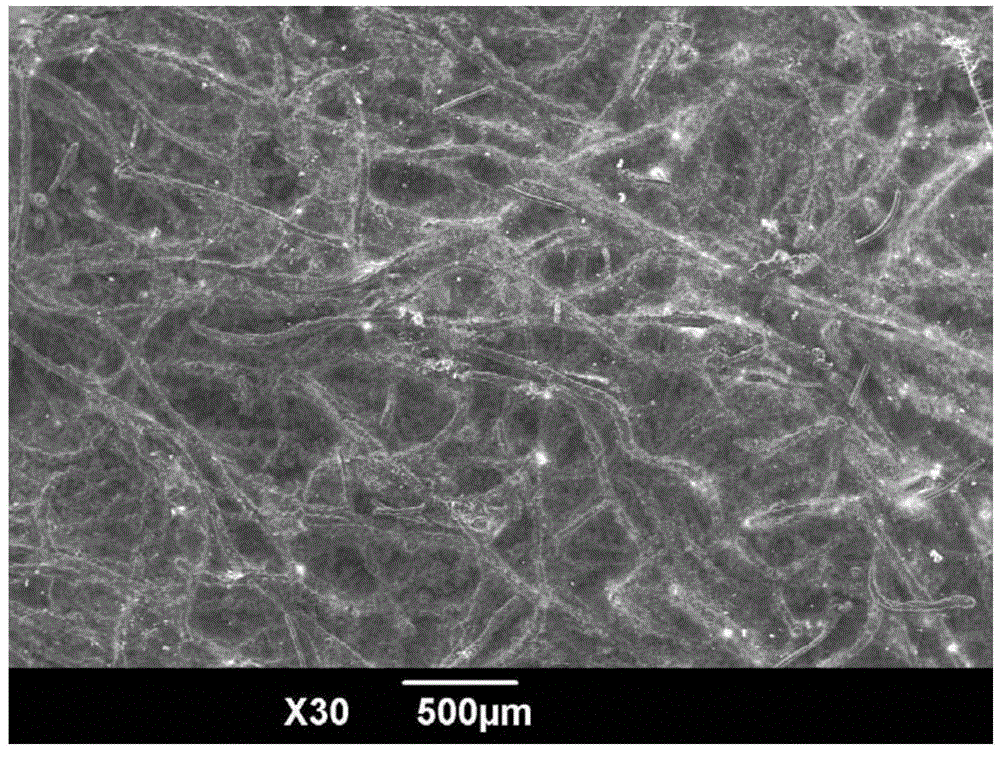

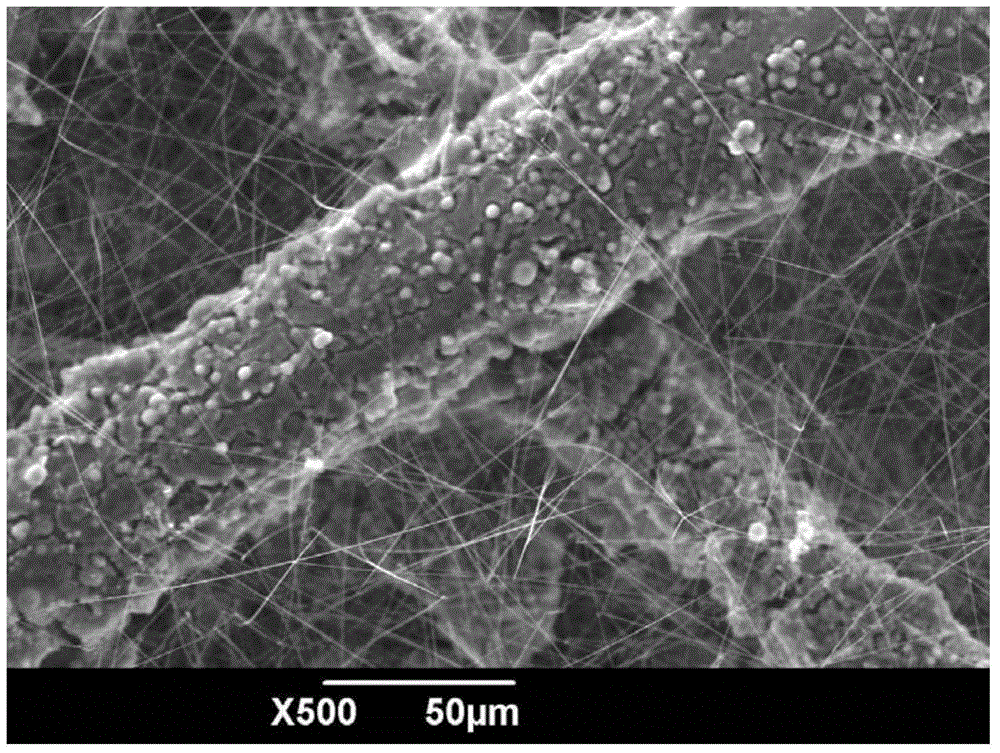

[0037] Step 3: Combine Si with SiO 2 Add the mixed powder and the carbon fiber skeleton dried in step 2 into the graphite crucible, and then put the graphite crucible into the vacuum sintering furnace. When the temperature rises to 1200°C, pass CO gas into the graphite crucible through the graphite ventilation tube for sintering 1 hour, and then naturally cooled to room temperature to obtain multi-scale structure SiC / C porous composite ceramics; wherein, S...

Embodiment 2

[0040] Step 1: Select a density of 0.6g / cm 3 The polyacrylonitrile-based carbon fiber felt is used as the carbon fiber skeleton;

[0041] Step 2: Put the carbon fiber skeleton selected in step 1 into a hydrothermal reaction kettle, then add sucrose solution as a carbon source precursor, deposit the carbon fiber skeleton for 8 hours at a reaction temperature of 250°C, and then take out the carbon fiber skeleton and dry it. Wherein, the concentration of the sucrose solution is 500g / L, and the ratio of the polyacrylonitrile-based carbon fiber felt to the sucrose solution is 2g:45mL.

[0042] Step 3: Combine Si with SiO 2 Add the mixed powder and the carbon fiber skeleton dried in step 2 into the graphite crucible, and then put the graphite crucible into the vacuum sintering furnace. When the temperature rises to 1500°C, pass CO gas into the graphite crucible through the graphite ventilation tube for sintering 3 hours, and then naturally cooled to room temperature to obtain mult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com