High-performance gas sensor based on laminated structure and preparation method for high-performance gas sensor

A technology of gas sensor and laminated structure, which is applied in the field of gas sensor to achieve the effect of improving performance, improving response recovery speed, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

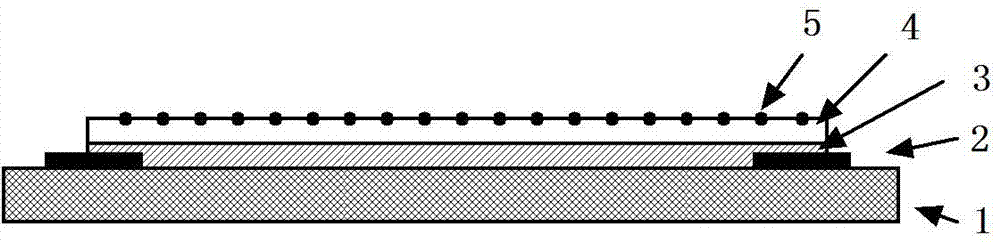

[0023] The invention provides a method for preparing an ordered composite gas sensor based on a heterogeneous structure, which specifically includes the following steps:

[0024] (1) Preparation of the substrate:

[0025] Select aluminum oxide, silicon oxide, glass or sapphire inert material as the substrate, ultrasonically clean the substrate in acetone solution to remove surface stains, then take out the substrate and wash off the residual organic solution with deionized water.

[0026] Metal conductive electrodes, such as gold, silver, and platinum, are fabricated on the substrate by screen printing or mask lithography to obtain a sensor substrate.

[0027] (2) Conductive layer preparation:

[0028] Tin oxide or zinc oxide is selected as a raw material, and a layer of conductive layer material is produced on the sensor substrate by screen printing, hydrothermal synthesis, and laser pulse deposition.

[0029] (3) Sensitive layer preparation:

example 1

[0035] Alumina was chosen as the substrate. The alumina substrate was ultrasonically cleaned in an acetone solution for 10 minutes to remove surface stains, and then the substrate was taken out and cleaned with deionized water to remove residual organic solution. The platinum conductive electrode platinum was fabricated on the substrate by screen printing to obtain the sensor substrate.

[0036] Select tin oxide powder as a raw material, fully mix terpineol, butyl carbitol acetate, and dibutyl phthalate according to a mass ratio of 6:3:1 to form an organic solvent, and then mix the tin oxide raw material powder with The organic solvents were mixed according to the mass ratio of 6:4, ball milled at a speed of 400 rpm for 3 hours to obtain a slurry, and a layer of tin oxide conductive layer material was printed on the sensor substrate by screen printing. Then put it into an oven at 120° C. and keep it warm for 2 hours, so that the conductive layer material is cured.

[0037] S...

example 2

[0040] Choose a glass material as the substrate. The glass substrate was ultrasonically cleaned in acetone solution for 10 minutes to remove surface stains, and then the substrate was taken out and cleaned with deionized water to remove residual organic solution. A silver conductive electrode is fabricated on the substrate by mask photolithography to obtain a sensor substrate.

[0041] Choose zinc nitrate as solute, take deionized water as solvent, prepare 0.05mol / L zinc element solution, add hexamethylenetetramine with zinc nitrate molar ratio 1: 1 as ammonia releasing agent, obtain zinc oxide growth solution, put The substrate was placed in a growth solution, and hydrothermal growth was performed at 90° C. for 4 hours. After taking it out, rinse it repeatedly with deionized water, and finally dry it in an oven at 80°C to obtain a conductive layer of zinc oxide.

[0042]After mixing concentrated hydrochloric acid and deionized water at a volume ratio of 1:1, drop tetrabutyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com