Vacuum electrothermal magnesium smelting apparatus with protector

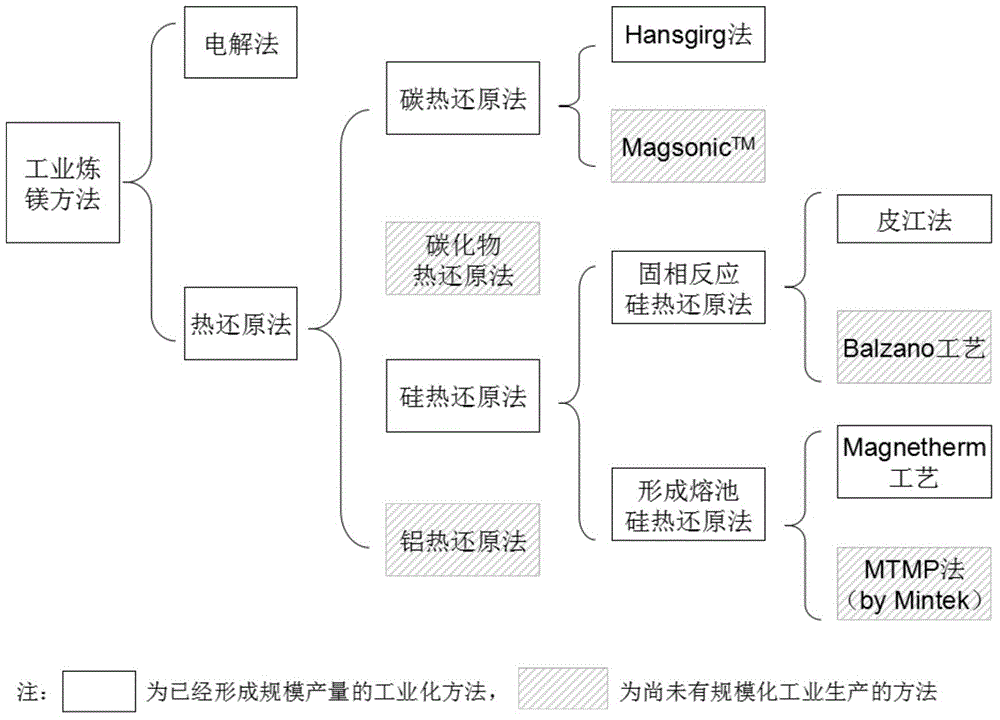

A protective device and vacuum technology, which is applied in the field of non-ferrous metal magnesium extraction and metallurgy, can solve problems such as harsh working environment, serious smoke pollution, and delay in production time, and achieve the effects of increasing smelting rate, strengthening specific surface area, and reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

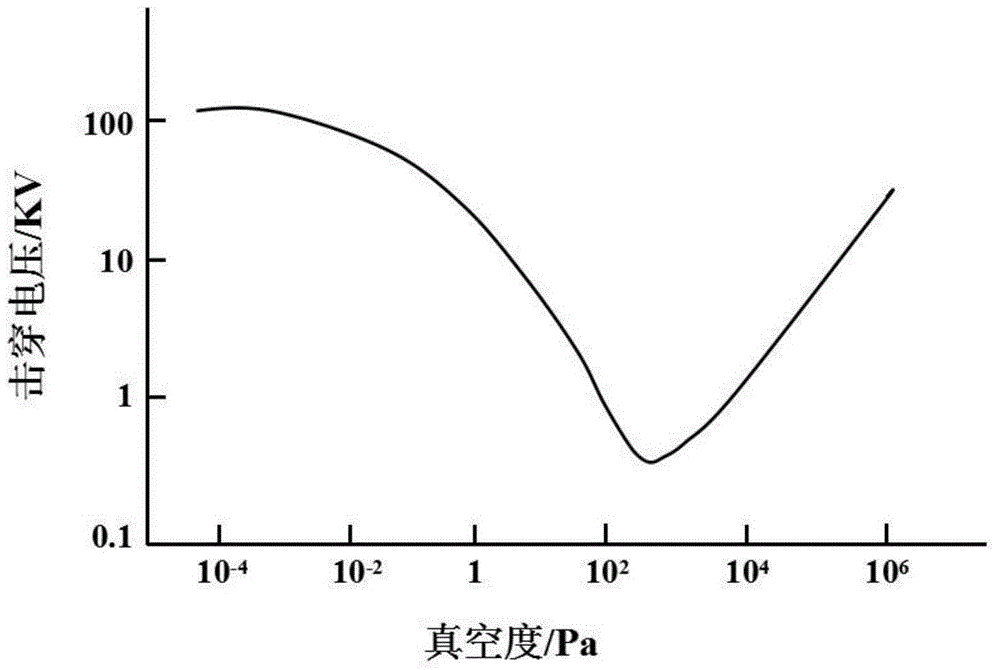

Method used

Image

Examples

Embodiment 1

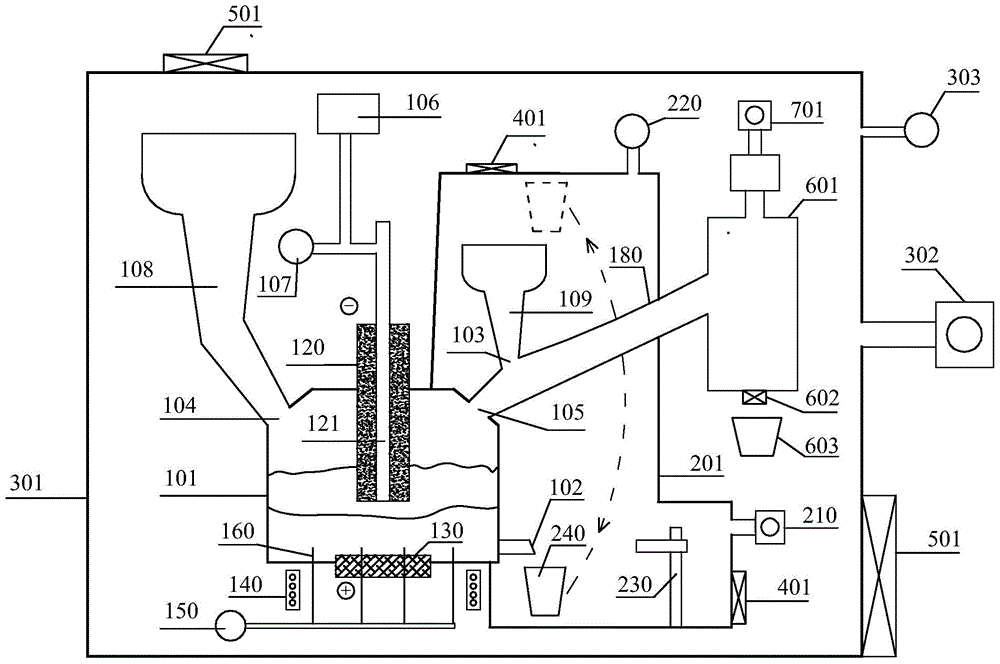

[0091] The vacuum electric furnace 101 is a vacuum direct current electric arc furnace, the furnace lining is made of carbonaceous refractory material, the upper part is a graphite hollow cathode 120, the graphite bottom anode 130 is located at the bottom of the furnace, and there is an arc stabilizing magnetic field generator 140 under the bottom anode 130. The coil of the arc stabilizing magnetic field generating device 140 generates a magnetic field after being energized, which can generate electromagnetic force on the DC arc generated between the hollow cathode 120 and the bottom anode 130, so that the arc tends to be stable after being stressed. The wall of the cathode cavity 121 inside the hollow cathode 120 is lined with a layer of thin steel plate, so as to protect the cathode cavity 121 inner wall of the graphite from being scoured by powdery charge, the top of the hollow cathode 120 is connected with a sealed mineral powder tank 106, and Connected to a hollow cathode ...

Embodiment 2

[0102] In this embodiment, 60% liquid ferrosilicon is used as the reducing agent, and the calcined dolomite is the raw material of magnesium ore, containing 23% magnesium, and the diameter is not more than 40mm. The maximum inner diameter of the middle part of the vacuum DC electric arc furnace is 6000mm, the inner diameter of the furnace bottom is 4200mm, and the inner height is 5100mm. The power of the DC power supply is 50MW, the maximum voltage is 800 volts, the current is 60-70KA, and the control temperature is 1600 degrees Celsius during normal operation. The graphite hollow cathode 120 has a diameter of 1300mm, the inner diameter of the cathode cavity 121 is 300mm, the pressure in the furnace is 10000Pa, the argon pressure in the hollow cathode 120 is 14000Pa, and calcined white powder with a diameter less than 6mm enters the hollow cathode 120 for feeding, accounting for 10% of the total magnesium ore. 16%, the diameter greater than 6mm is fed into the furnace through ...

Embodiment 3

[0106] The vacuum electric furnace 101 is a closed medium-frequency electromagnetic induction electric furnace with a frequency of 100 Hz and a rated power of 20,000 kW, which is heated by induction heating with a water-cooled copper coil. The internal charging volume is 60 tons of liquid steel material. Since the density of ferrosilicon is lower than that of steel, the mass of molten ferrosilicon loaded during the actual magnesium smelting operation is about 30-40 tons. The top of the vacuum induction furnace 101 is provided with a liquid injection port 103 , a feeding port 104 and a magnesium vapor outlet 105 . All the magnesium ores are lumps of more than 3 mm in size, and all of them are fed into the furnace from the storage tank 108 through the feeding port 104 . The ferrosilicon liquid is added into the furnace from the ferrosilicon liquid injection tank 109 installed above the liquid injection port 103 . The bottom of the furnace is equipped with a bottom blowing argon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com