Grade-A fireproof material based on ABS (acrylonitrile-butadiene-styrene) plastic

A technology of ABS plastic and fireproof material, which is applied in the field of compositions containing acrylonitrile butadiene styrene polymer, can solve the problem that the fireproof performance will not work, and achieve the effect of reducing the decomposition rate and reducing the ambient temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: Preparation of flame retardant polyether

[0037] A cylindrical airtight reaction vessel with a height of 2 meters, an arc generator is arranged in the reaction vessel, and a microwave generator is arranged at a height of 1.5m on the wall of the reactor. Before the reaction starts, the container is filled with nitrogen and carbon dioxide (volume ratio 100:2) after vacuuming, so that the pressure in the container is 75 MPa.

[0038] The catalyst is a mixture of 0.6 parts by mass of methanol, 0.5 parts by mass of silicone oil, 0.3 parts by mass of sodium silicate, and 0.1 parts by mass of sodium bicarbonate.

[0039] Rare earth bromide (purchased from Yixing Xinweilicheng Rare Earth Co., Ltd., 2000 mesh) with mass parts of 1, 0.5, 1.5, and 1.5, butylene oxide, catalyst, and polytetrafluoroethylene at a temperature of 560 ° C and a pressure Under the reaction conditions of 75 MPa, voltage of 15,000 volts, and microwave frequency of 100 GHz, it was obtained a...

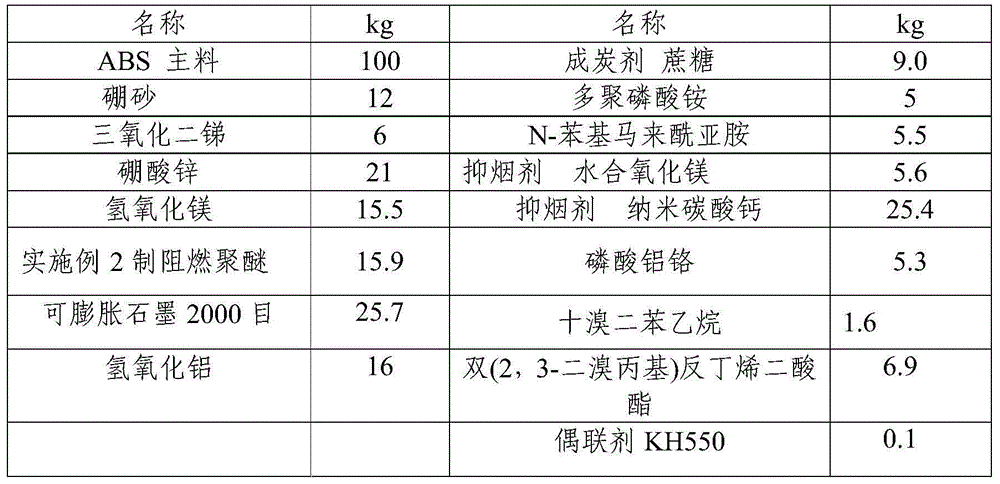

Embodiment 2

[0040] Embodiment 2: Preparation of flame retardant polyether

[0041] Equipment and pressure control are the same as in Example 1.

[0042] The catalyst is a mixture of 0.7 parts by mass of methanol, 0.6 parts by mass of silicone oil, 0.5 parts by mass of sodium silicate, and 0.2 parts by mass of sodium bicarbonate.

[0043] The mass parts of cerium bromide, butylene oxide, catalyst, and polytetrafluoroethylene are 1, 0.5, 2.0, and 1.5 respectively. Obtained after 3 hours of reaction.

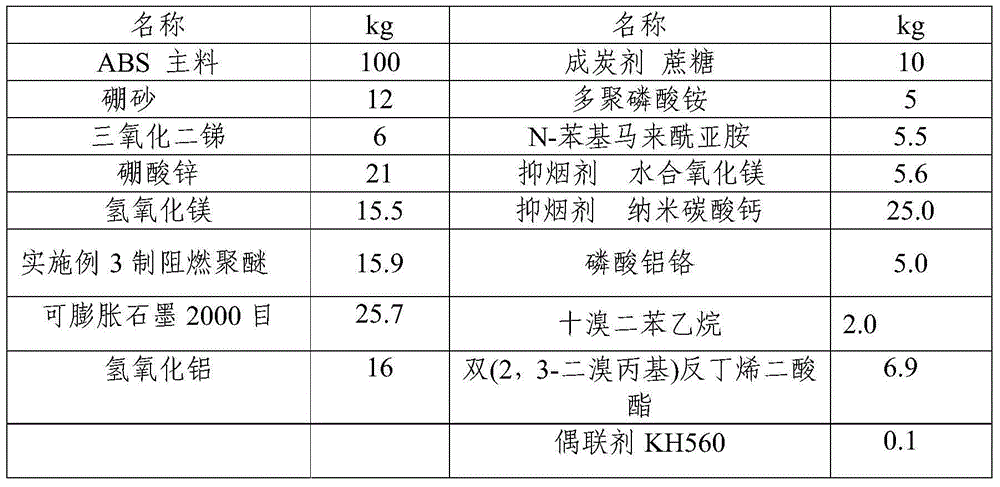

Embodiment 3

[0044] Embodiment 3: Preparation of flame retardant polyether

[0045] Equipment and pressure control are the same as in Example 1.

[0046] Catalyst is with embodiment 2. The mass parts are respectively 1, 0.5, 2.0, 1.5 lanthanum bromide (purchased from Yixing Xinwei Licheng Rare Earth Co., Ltd.), butylene oxide, catalyst, and polytetrafluoroethylene at a temperature of 550 ° C and a pressure of 75 MPa. Under the reaction conditions of a voltage of 15,000 volts and a microwave frequency of 100 GHz, it was obtained after 3 hours of reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com