Titanium alloy artificial articular head with wear resistant ceramic coating and preparation method of titanium alloy artificial articular head

A wear-resistant ceramic and artificial joint technology, applied in coatings, surface reaction electrolytic coatings, electrolytic coatings, etc., can solve the problems of poor lubrication of replacement joints, inability to make joint heads, and wear resistance of titanium alloys. Achieve the effect of reducing joint head loosening, high density, and improving hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

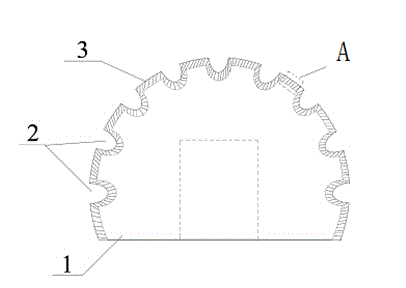

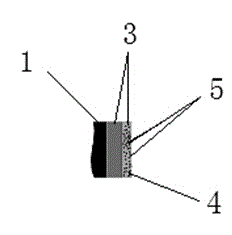

[0024] A titanium alloy artificial joint head with wear-resistant ceramic coating, the artificial joint head includes a titanium alloy joint head body 1 with a micropore array texture 2 formed on the surface, and a friction-reducing and wear-resistant ceramic coating is provided on the surface of the titanium alloy joint head body 1 Layer 3, the surface layer of the anti-friction and wear-resistant ceramic coating 3 is a dense ceramic layer 4 filled and sealed with hard nanoparticles 5 . Hard nanoparticles are SiO 2 particles.

[0025] A kind of nano-SiO 2 A method for preparing the surface texture of the particle-filled and sealed titanium alloy artificial joint head and a vitrified wear-resistant coating. The specific preparation steps are as follows:

[0026] 1) Polish the outer circular surface of the titanium alloy joint head body;

[0027] 2) Laser etching technology is used to texture the surface of the titanium alloy joint head body to form a regular micropore array...

Embodiment 2

[0033] A kind of wear-resistant ceramic coating titanium alloy artificial joint head, structure is the same as embodiment 1, and hard nano particle is Al 2 o 3 particles.

[0034] A nano-Al 2 o 3 A method for preparing the surface texture of the particle-filled and sealed titanium alloy artificial joint head and a vitrified wear-resistant coating. The specific preparation steps are as follows:

[0035] 1) Polish the outer circular surface of the titanium alloy joint head;

[0036] 2) The titanium alloy joint head is textured by photolithography micro-electrolytic machining technology to form a regular micropore array, the micropore diameter D=100 μm, the micropore depth h=10 μm, and the micropore area occupancy rate S=20% .

[0037] 3) Using HF-HNO 3 The solution cleans the textured joint head to remove surface oxides;

[0038] 4) Perform the first step of plasma electrolytic oxidation treatment in the silicate / phosphate mixed electrolyte, the electrolyte contains 8g / L ...

Embodiment 3

[0042] A nano-Si 3 N 4 A method for preparing the surface texture of the particle-filled and sealed titanium alloy artificial joint head and a vitrified wear-resistant coating. The specific preparation steps are as follows:

[0043] 1) Polish the outer circular surface of the titanium alloy joint head;

[0044] 2) The mechanical indentation method was used to texture the titanium alloy joint head to form a regular micropore array. The micropore diameter D=1000 μm, the micropore depth h=55 μm, and the micropore area occupancy rate S=5%.

[0045] 3) Using HF-HNO 3 The solution cleans the textured joint head to remove surface oxides;

[0046] 4) The first step of plasma electrolytic oxidation treatment is carried out in the silicate / phosphate mixed electrolyte. The electrolyte contains 10g / L sodium silicate and 6g / L sodium phosphate. The power supply voltage is 600V, the pulse frequency is 800Hz, and the duty cycle 20%, processing time 30min;

[0047] 5) Containing nano-Si w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com