Preparation method of magnetic silicon carbide ceramic nano particles

A technology of silicon carbide ceramics and nanoparticles, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as easy agglomeration, reduced product stability, and non-uniform dispersion of nano-iron powder. To achieve the effect of enhancing the dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, a kind of preparation method of magnetic silicon carbide ceramic nanoparticles, carries out following steps successively:

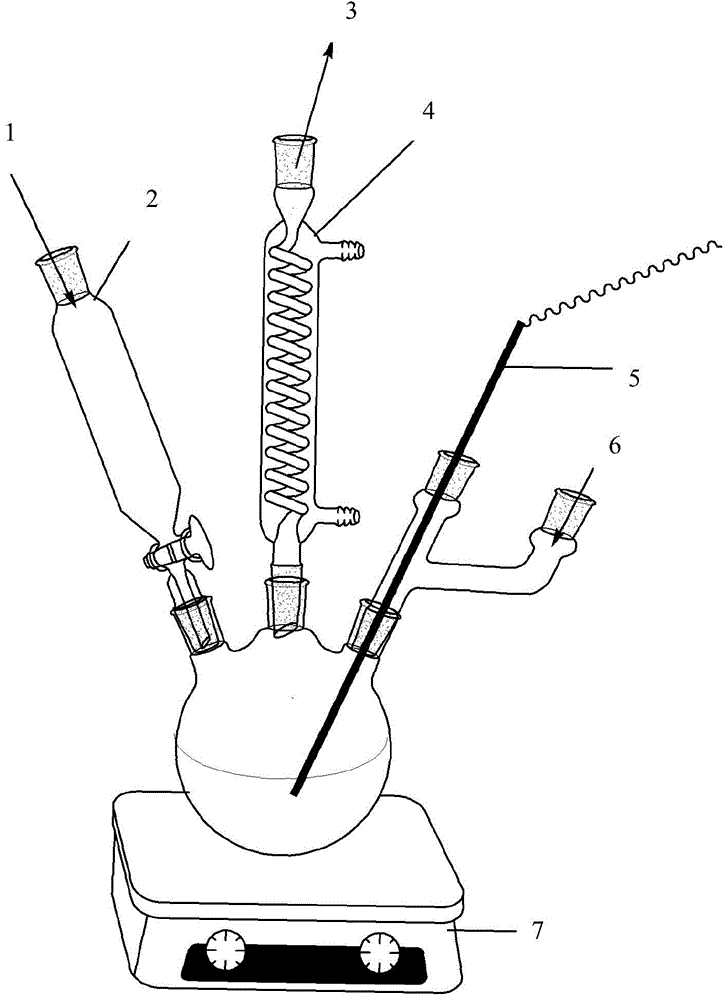

[0030] 1) Preparation of iron sol: check figure 1 (exist figure 1 Among them, each mark is: 1. reactant; 2. dropping funnel; 3. gas; 4. serpentine condenser; 5. thermocouple; 6. argon; 7. magnetic stirrer) Vacuumize, fill with high-purity argon, and repeat the operation three times. Under the protection of high-purity argon, inject iron acetylacetonate, polycarbosilane and xylene (mass ratio is 3:1:10) into the reaction system, and the high-purity argon After purging for 30 minutes, heat to 120° C., keep the temperature constant for 48 hours, and cool to room temperature to obtain a black iron sol solution.

[0031] 2) Mixing of iron sol and asphalt: dissolve petroleum asphalt in an appropriate amount of xylene, then add iron sol under mechanical stirring (the mass ratio of asphalt to iron sol is 9:1), and increase the temperature a...

Embodiment 2

[0035] Embodiment 2, a kind of preparation method of magnetic silicon carbide ceramic nanoparticles, carries out following steps successively:

[0036] 1) Preparation of cobalt sol: check figure 1 The airtightness of the medium device is evacuated, filled with high-purity argon, and the operation is repeated 3 times. Under the protection of high-purity argon, (cyclopentadiene) cobalt, polycarbosilane and petroleum ether (mass ratio is 2: 1:40) into the reaction system, purged with high-purity argon for 30 minutes, heated to 90°C, kept at a constant temperature for 48 hours, and cooled to room temperature to obtain a black iron sol solution.

[0037]2) Mix cobalt sol with asphalt: dissolve petroleum asphalt in an appropriate amount of petroleum ether, then add iron sol (the mass ratio of asphalt to cobalt sol is 5:1) under mechanical stirring, and increase the temperature at the programmed temperature at 5°C / min Stir for 10 minutes after reaching the boiling point of petroleum...

Embodiment 3

[0041] Embodiment 3, a kind of preparation method of magnetic silicon carbide ceramic nanoparticles, carries out following steps successively:

[0042] 1) Preparation of nickel sol: check figure 1 The airtightness of the medium device is vacuumized, filled with high-purity argon, and the operation is repeated three times. Under the protection of high-purity argon, nickel acetylacetonate, polycarbosilane and N, N dimethylformamide (mass ratio of 5 : 2: 100) into the reaction system, purged with high-purity argon for 30 minutes, heated to 170 ° C, kept at a constant temperature for 10 hours, and cooled to room temperature to obtain a black nickel sol solution.

[0043] 2) Mixing of nickel sol and asphalt: dissolve petroleum asphalt in an appropriate amount of N, N dimethylformamide, then add nickel sol under mechanical stirring (the mass ratio of asphalt to iron sol is 7:1), at the programmed temperature Raise to the boiling point of N,N dimethylformamide at 5°C / min, stir for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com