Preparation method of nano-silica with surface grafted with polystearylmethacrylate

A technology of polystearyl methacrylate and nano-silica, which is applied in the directions of dyeing organosilicon compound treatment, dyeing macromolecular organic compound treatment, fibrous filler, etc. The molecular structure and molecular weight are very different, and the polymer chains cannot penetrate each other, so as to increase the glass transition temperature, improve the shielding effect, and suppress the space charge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

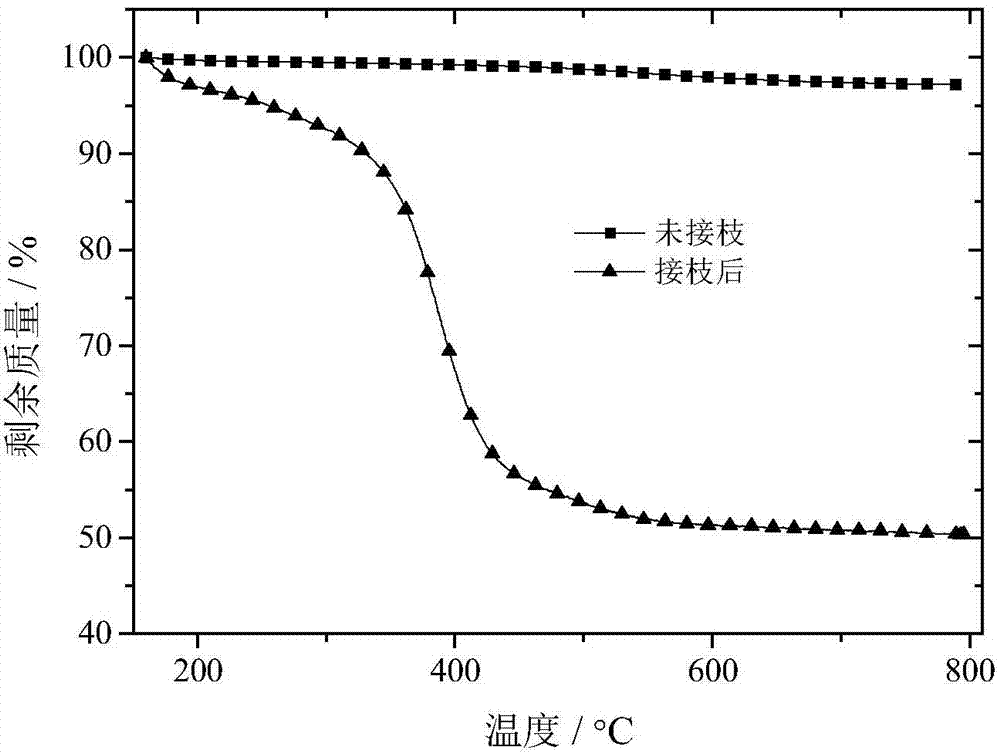

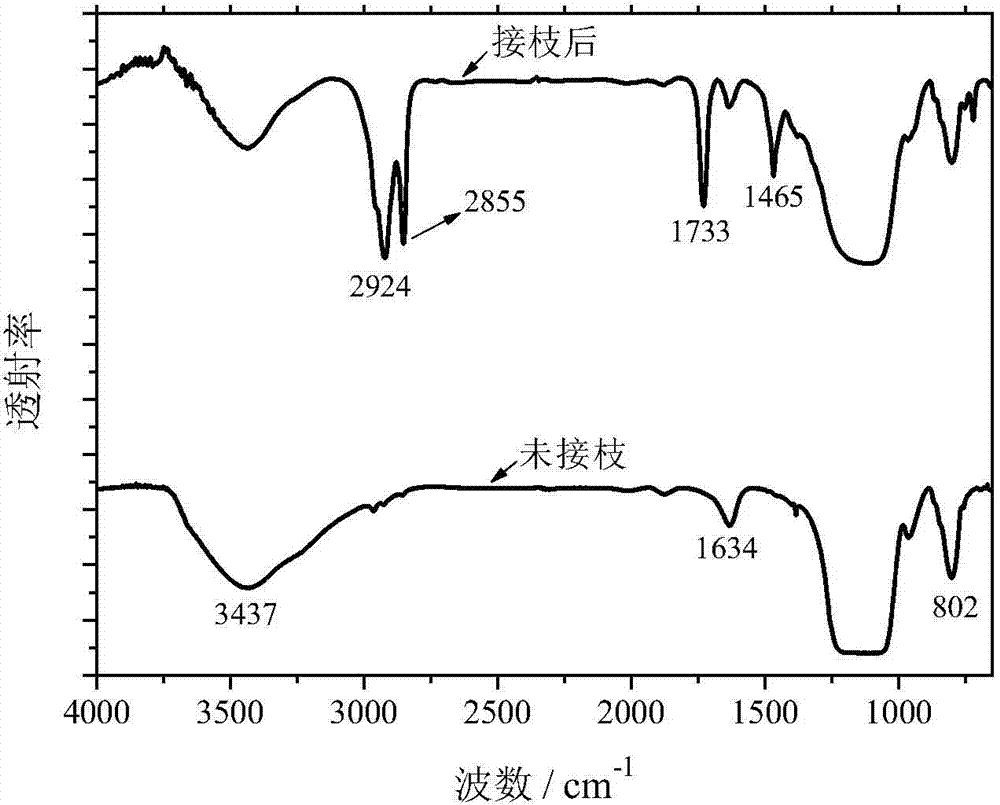

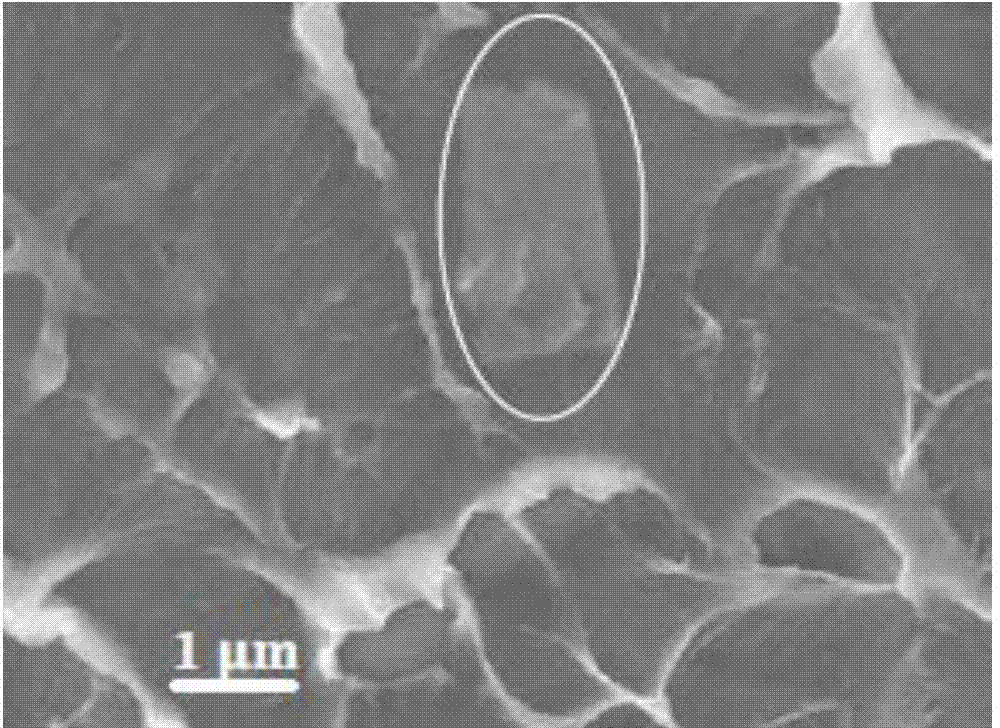

[0020] The preparation method of the surface grafted polyoctadecyl methacrylate nano silicon dioxide that the present invention proposes comprises the following steps:

[0021] (1) First disperse silicon dioxide in a strong polar solvent to obtain a silicon dioxide solution with a mass percentage concentration of 10% to 40%. The strong polar solvent is: methanol, ethanol, methyl ethyl ketone, chloroform , tetrahydrofuran or toluene; add aminosilane to the silica solution so that the molar concentration of aminosilane in the silica solution is 1-10mol / L, and reflux at 50-120°C for 5-24 hours in a nitrogen atmosphere , to obtain the first mixed solution, the aminosilane is 3-aminopropyltriethoxysilane, 3-aminopropyltrimethoxysilane, 3-aminopropyldimethylmethoxysilane or 4-aminobutyl Base triethoxysilane; at normal temperature, n-hexane is added to the first mixed solution, and the volume ratio is: n-hexane: first mixed solution=(5~15): 1, after waiting for the solid to completel...

Embodiment 1

[0026] (1) At first, silicon dioxide is dispersed in methanol to obtain a silicon dioxide solution with a mass percent concentration of 30%; 3-aminopropyltriethoxysilane is added to the silicon dioxide solution to make 3-aminopropyl The molar concentration of triethoxysilane in the silicon dioxide solution is 3 mol / L, and in a nitrogen atmosphere, reflux at 60°C for 12 hours to obtain the first mixed solution; add n-hexane to the first mixed solution at normal temperature, The adding volume ratio is: n-hexane: the first mixed solution=10:1, after waiting for the solid to precipitate completely, the mixture is centrifuged, and the separated solid is dissolved in the above-mentioned methanol to obtain a mass volume concentration of 0.3g / mL of solution; repeat the steps of precipitation-centrifugation-dissolution, and finally obtain the nano-silica solution of surface-grafted aminosilane, which is denoted as the first solution;

[0027] (2) Cumyl dithiobenzoate is added to the m...

Embodiment 2

[0035] (1) At first, silicon dioxide is dispersed in ethanol to obtain a silicon dioxide solution with a mass percent concentration of 30%; 3-aminopropyltriethoxysilane is added to the silicon dioxide solution to make 3-aminopropyl The molar concentration of triethoxysilane in the silicon dioxide solution is 3 mol / L, and in a nitrogen atmosphere, reflux at 60°C for 12 hours to obtain the first mixed solution; add n-hexane to the first mixed solution at normal temperature, The adding volume ratio is: n-hexane: the first mixed solution=10:1, after waiting for the solid to precipitate completely, the mixture is centrifuged, and the separated solid is dissolved in the above-mentioned ethanol to obtain a mass volume concentration of 0.3g / mL of solution; repeat the steps of precipitation-centrifugation-dissolution, and finally obtain the nano-silica solution of surface-grafted aminosilane, which is denoted as the first solution;

[0036] (2) Cumyl dithiobenzoate is added to the eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com