A boron-containing gradient cemented carbide with a shell structure and its preparation method

A technology of cemented carbide and shell structure, which is applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of small amount of boron-containing phases on the surface, prolongation, and reduced performance, and achieve sudden failure Risk reduction, increased hardness and wear resistance, elimination of negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034]A boron-containing gradient cemented carbide with a shell structure of the present invention has a three-layer structure of the surface layer, the subsurface layer and the core from the innermost layer of the boron-containing gradient cemented carbide; the surface layer is a boron-containing phase with uniform distribution The shell structure, the subsurface layer is a gradient transition structure with uniform changes in boron-containing phases, and the core is a cemented carbide structure without boron-containing phases; and the boron-containing phase concentration gradually decreases from the interface between the surface layer and the subsurface layer to the subsurface layer. The skin and core interface completely disappears.

[0035] The thickness of the surface layer of the boron-containing gradient cemented carbide is greater than or equal to 1 mm.

[0036] The boron-containing phase quantity, binder phase content and hardness in the surface layer of the boron-con...

Embodiment 1

[0053] Boronizing heat treatment is carried out on cemented carbide buttons (about 16mm in diameter and about 25mm in height) containing 6wt.% Co, and the filler component is ZrO containing 1wt.% BN 2 , add a small amount of toner. The boronizing equipment is a vacuum integrated furnace, the boronizing temperature is 1360°C, the time is 0.5h, and 10mbar Ar is introduced as a carrier.

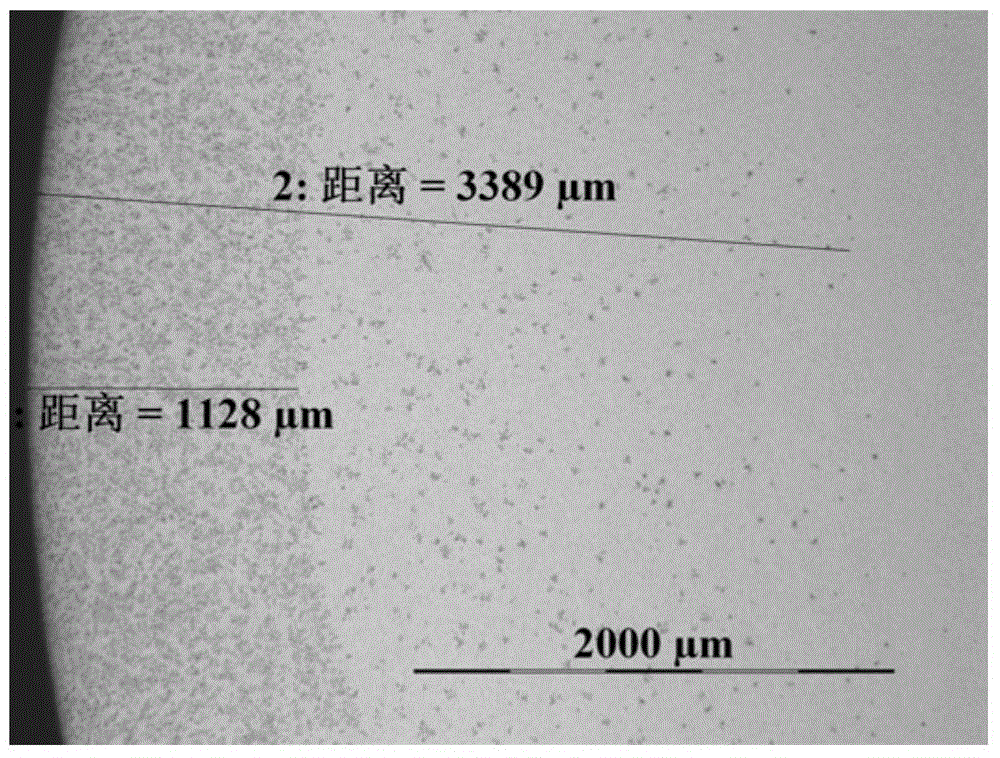

[0054] After boronizing, take out the cemented carbide ball tooth sample, use the wire cutting method to intercept the column body, after flat grinding and polishing, use 10% K 3 [Fe(CN) 6 ]+10%NaOH aqueous solution for light corrosion to obtain the metallographic structure of the sample as follows figure 1 shown.

[0055] figure 1 It shows that after boronizing treatment, a layer of boronizing shell with a thickness of more than 1mm is formed on the surface of the alloy button. Between the boronizing shell and the alloy core, there is a transition layer with boron-containing phase disperse...

Embodiment 2

[0058] Boronizing heat treatment is carried out on cemented carbide buttons (about 19mm in diameter and about 28mm in height) containing 6wt.% Co, and the filler composition is 1wt.% B 4 Al of C 2 o 3 , add a small amount of toner. The boronizing equipment is an atmospheric molybdenum wire furnace, the boronizing temperature is 1320°C, the time is 45 minutes, and the atmosphere in the furnace is Ar+10vol.%H 2 mixed composition.

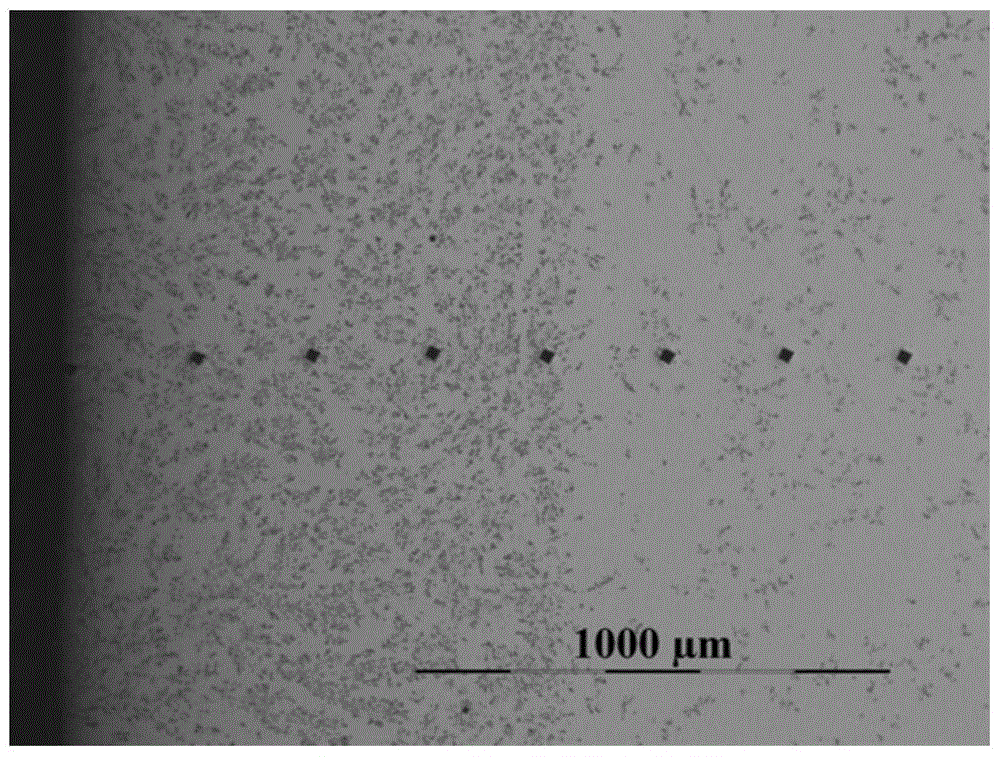

[0059] After boronizing, take out the cemented carbide ball tooth sample, use the wire cutting method to intercept the column body, after flat grinding and polishing, use 10% K 3 [Fe(CN) 6 ]+10%NaOH aqueous solution for light corrosion to obtain the metallographic structure of the sample as follows figure 2 shown.

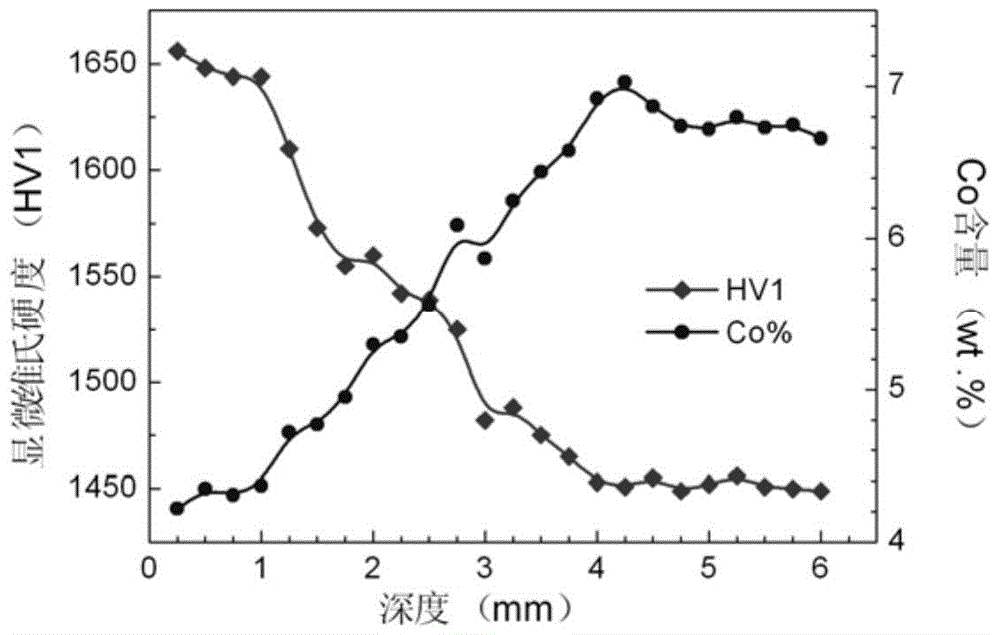

[0060] The micro-hardness change of the boronizing layer was measured by the Tukon2100B micro-Vickers hardness tester of Wilson Company. image 3 shown. The test pressure is 1kgf, and the distance between test points is 0.25mm. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com