Molybdate-based red fluorescent powder and preparation method thereof

A red phosphor, molybdate technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of pollution, low luminous efficiency of devices, complicated preparation methods, etc., and achieve rich sources, simple and easy preparation methods, and Preparation method flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

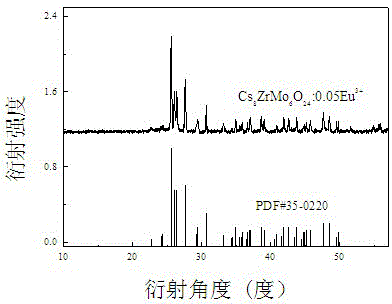

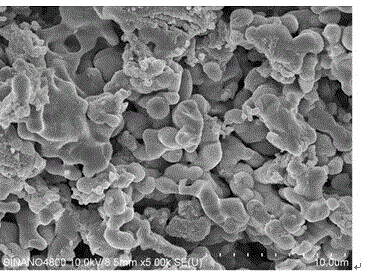

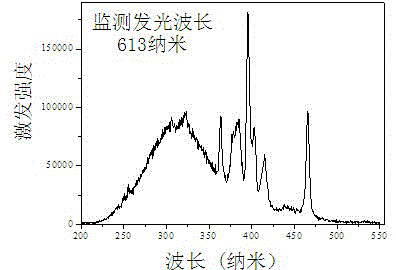

[0034] Preparation of Cs 8 Zr 6 o 24 :0.05Eu 3+ : According to the chemical formula Cs 8 Zr 6 o 24 :0.05Eu 3+ , respectively weigh cesium carbonate Cs 2 CO 3 : 2.477 g, europium oxide Eu 2 o 3 : 0.141 g, Zirconia ZrO 2 : 0.247 g, ammonium molybdate (NH 4 ) 6 Mo 7 o 24 -4H 2 O: 2.119 grams, after grinding and mixing in an agate mortar, select the air atmosphere for pre-calcination, the pre-calcination temperature is 300 ° C, the pre-calcination time is 14 hours, then cool to room temperature, take out the sample; the first calcined The raw materials are fully mixed and ground again, and the second pre-calcination is carried out in the air atmosphere. The pre-calcination temperature is 650 ° C, the pre-calcination time is 3 hours, and then cooled to room temperature, and the sample is taken out; finally, the obtained mixture is fully ground again and put In the furnace, it is calcined under the air atmosphere, the calcining temperature is 900° C., and the calcini...

Embodiment 2

[0041] Preparation of Cs 8 Zr 6 o 24 :0.0001Eu 3+ : According to the chemical formula Cs 8 Zr 6 o 24 :0.0001Eu 3+ , respectively weigh cesium nitrate CsNO 3 : 3.116 g, europium oxide Eu 2 o 3 : 0.0003 g, zirconium sulfate tetrahydrate Zr (SO 4 ) 2 -4H 2 O: 0.7109 g, molybdenum oxide MoO 3 : 1.7273 grams, after grinding and mixing in an agate mortar, select the air atmosphere for pre-calcination, the pre-calcination temperature is 500 ° C, the pre-calcination time is 10 hours, then cool to room temperature, take out the sample; the raw material calcined for the first time Thoroughly mix again and grind evenly, carry out the second pre-calcination in the air atmosphere, the pre-calcination temperature is 650 ° C, the pre-calcination time is 7 hours, then cool to room temperature, take out the sample; finally the obtained mixture is fully ground again and placed in the muffle furnace , calcined in an air atmosphere, the calcined temperature is 650 ° C, and the calcin...

Embodiment 3

[0043] Preparation of Rb 8 Zr 6 o 24 :0.01Eu 3+ : According to the chemical formula Rb 8 Zr 6 o 24 :0.01Eu 3+ , respectively weigh rubidium carbonate Rb 2 CO 3 : 1.829 g, europium nitrate Eu (NO 3 ) 3 ·6H 2 O: 0.0714 g, zirconia ZrO 2 : 0.2465 g, ammonium molybdate (NH 4 ) 6 Mo 7 o 24 4H 2 O: 2.119 grams, after grinding and mixing uniformly in an agate mortar, select the air atmosphere for pre-calcination, the pre-calcination temperature is 650 ° C, the pre-calcination time is 7 hours, then cool to room temperature, take out the sample; the pre-calcined raw materials are again Thoroughly mix and grind evenly, calcined in an air atmosphere in a muffle furnace, the calcining temperature is 800°C, and the calcining time is 9 hours, and the powdered molybdate-based red phosphor is obtained. Its microstructure, excitation spectrum, and luminescence Spectrum and decay curve are similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com