A low-temperature solid oxide fuel cell supported by porous metal and its preparation method

A solid oxide and fuel cell technology, applied in fuel cells, battery electrodes, circuits, etc., can solve the problems of high ohmic impedance, low electrical conductivity, and inability to meet low-temperature SOFC working requirements, etc., and achieve low ohmic loss and mechanical strength High, fast and repeated start-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

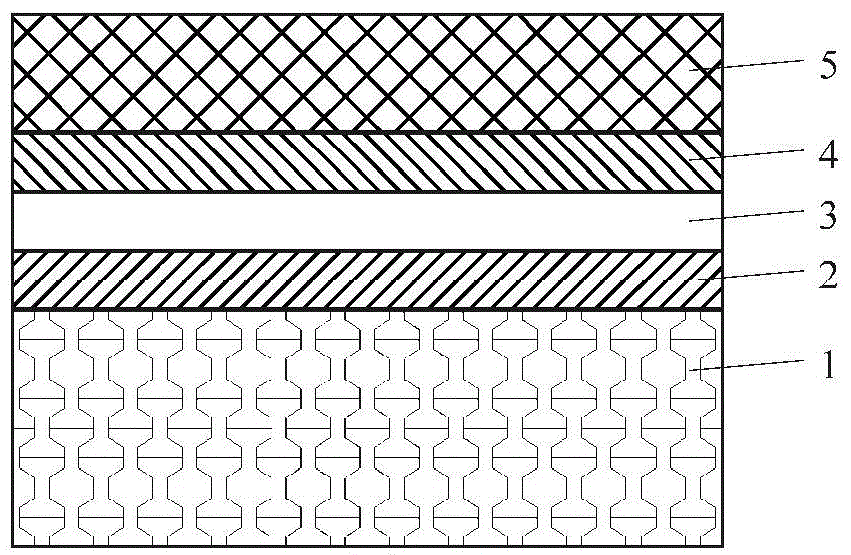

[0031] Such as figure 1 As shown, the low-temperature solid oxide fuel cell includes a porous metal support 1, an anode reaction layer 2, an electrolyte membrane 3, a cathode reaction layer 4, and a cathode current collecting layer 5.

[0032] In this embodiment, the plate-shaped porous metal support 1 uses foamed metal Ni, and its porosity is 50%. The anode reaction layer 2 uses a Ni-GDC (Gd doped cerium oxide) anode with a thickness of 20 μm. The electrolyte film 3 is also GDC with a thickness of 15 μm and is prepared by electrochemical vapor deposition. Cathode functional layer 4 is (La,Sr)(Co,Fe)O 3 The composite cathode composed of GDC and GDC has a thickness of 20μm.

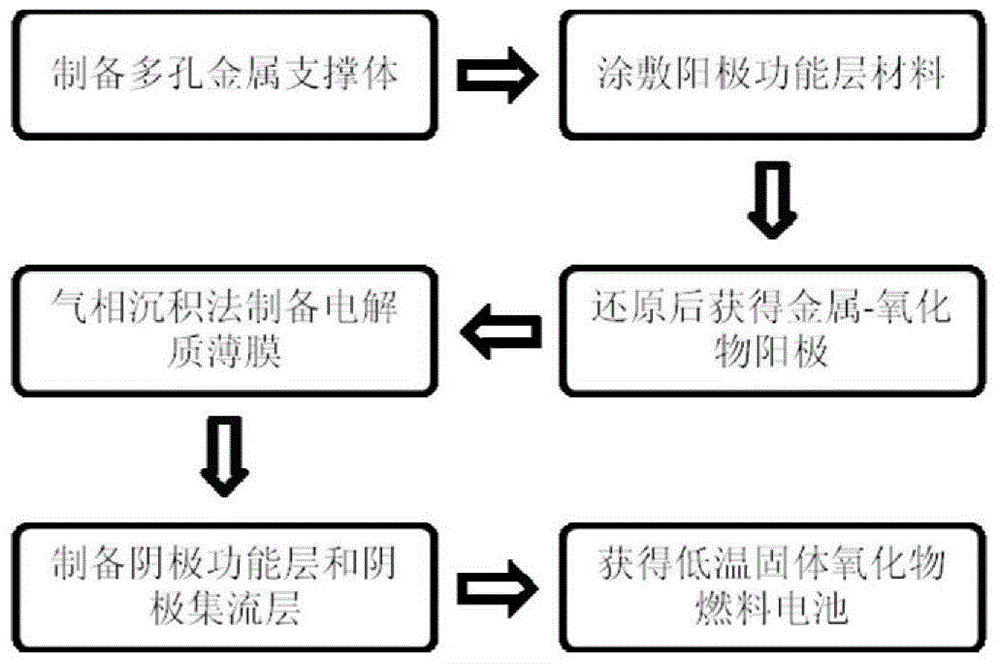

[0033] Such as figure 2 As shown, the preparation method of the low-temperature solid oxide fuel cell is as follows:

[0034] (1) Prepare a flat metal support 1 made of foamed metal Ni;

[0035] (2) The anode material mixed with NiO and GDC is coated on the porous metal support 1, and the Ni-SDC anode reaction ...

Embodiment 2

[0040] The difference from Example 1 is that the metal support 1 is changed to a foamed Ni-Fe alloy, the porosity is 30%, the anode reaction layer 2 is NiCo-GDC, the thickness is 50 μm, and the reduction temperature is 400°C. The electrolyte film is changed to SDC (Sm doped cerium oxide), which is prepared by magnetron sputtering, with a thickness of 0.5 μm.

[0041] The maximum power density of the obtained single cell reaches 0.37 and 0.24W / cm at 600℃ and 500℃, respectively 2 , The corresponding current density is 0.92 / cm 2 And 0.75A / cm 2 .

Embodiment 3

[0043] The difference from Example 1 is that the metal support 1 is changed to a foamed Ni-Cr alloy with a porosity of 80%, and the anode reaction layer 2 is Ni / Pt (bimetal)-SDC (the Pt metal uses chloroplatinic acid It is the precursor), the thickness is 5μm. The electrolyte membrane is changed to Mg and Y co-doped cerium oxide, the thickness of the electrolyte membrane is 5μm, and the cathode functional layer is changed to (Sm,Sr)(Co)O 3 The composite cathode composed of SDC and SDC has a thickness of 50μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com