A Micro Electrochemical Reactor Based on Microfluidic Technology

A microfluidic technology and electrochemical technology, applied in the field of electrochemical reaction, can solve the problems of decreasing effective concentration and increasing pH on the surface of cathode catalyst, achieving the effects of low ohmic loss, large electrochemical active area, and reduced internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

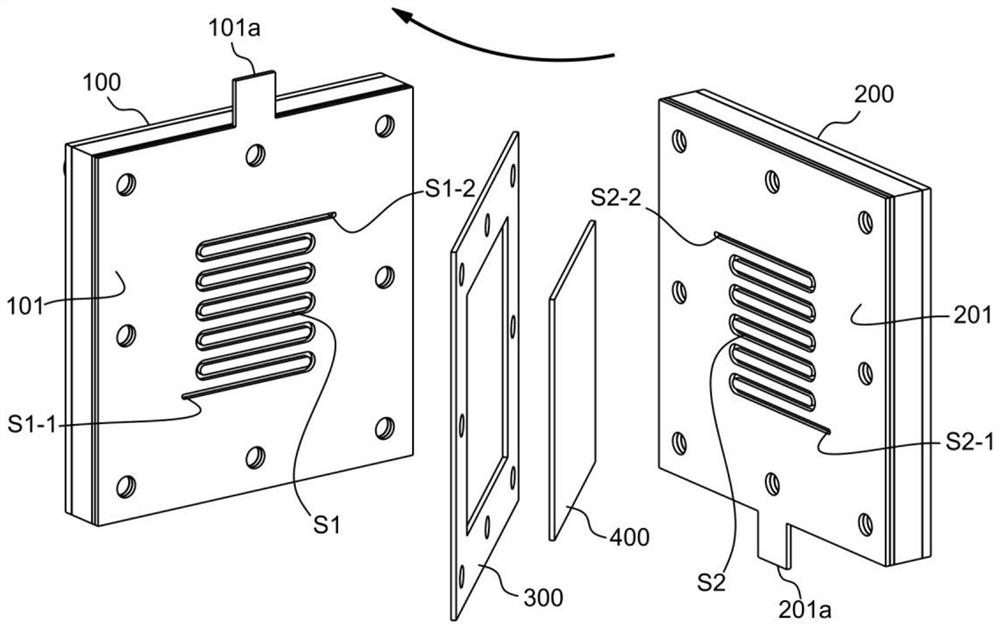

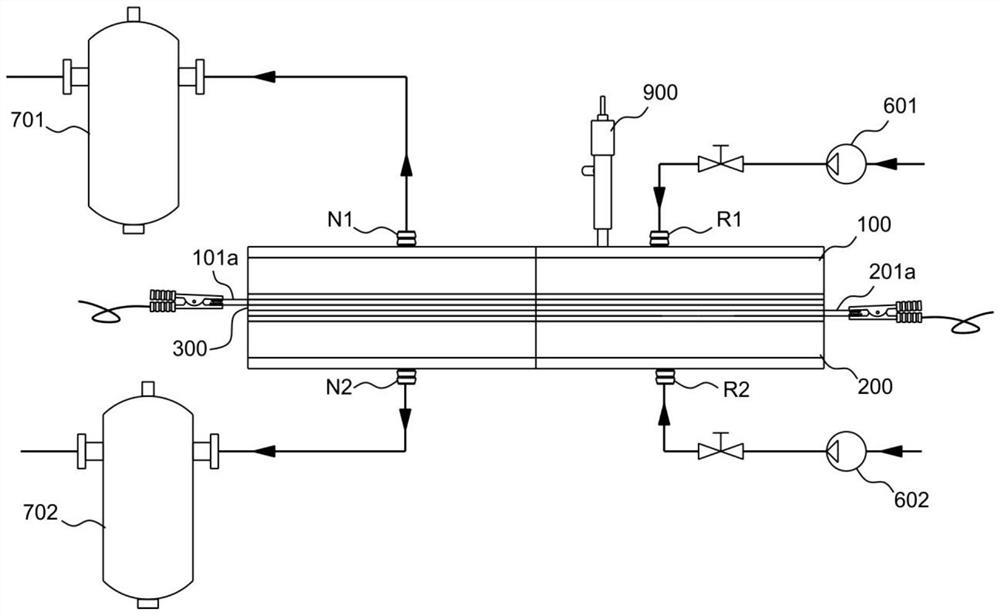

[0054] refer to figure 1 , which is the first embodiment of the present invention, this embodiment provides a micro-electrochemical reactor based on microfluidic technology, including a cathode assembly 100 and an anode assembly 200, and the anode assembly 200 and the cathode assembly 100 face each other; The assembly 100 is isolated from the anode assembly 200 by an insulator 300;

[0055] Wherein, a flow channel S1 is formed in the cathode assembly 100, a flow channel S2 is formed in the anode assembly 200, and the flow channel S1 communicates with the introduction flow channel R1 and the discharge flow channel N1 respectively, and the fluid is introduced from the introduction flow channel R1 to the flow channel S1 Among them, the fluid in the flow channel S1 is discharged from the discharge channel N1; the flow channel S2 communicates with the introduction flow channel R2 and the discharge flow channel N2 respectively, and the fluid is introduced into the flow channel S2 fr...

Embodiment 2

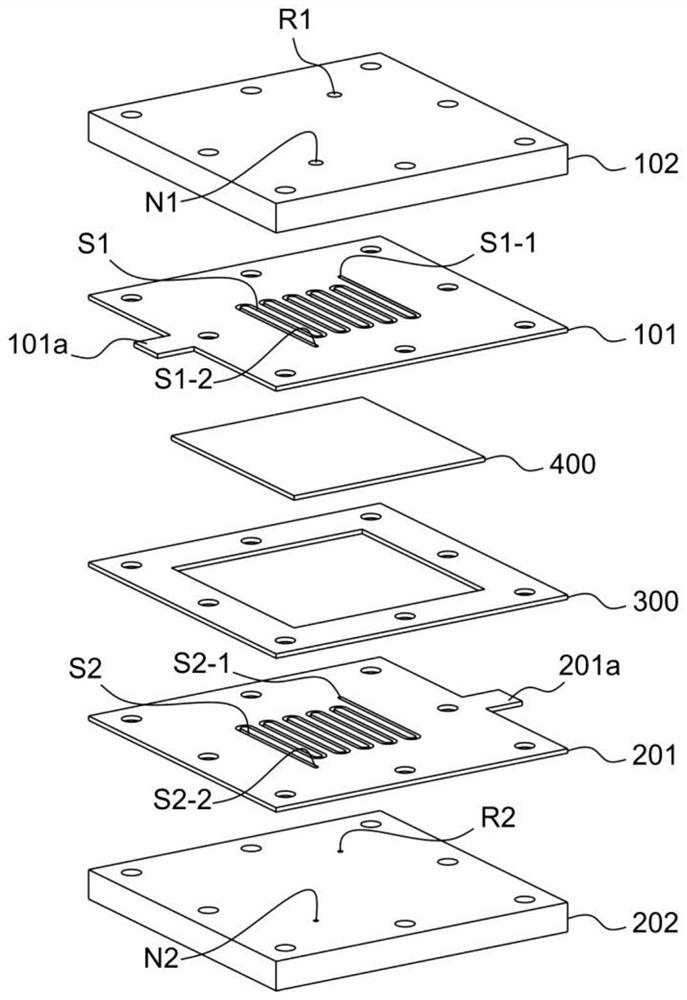

[0059] refer to Figure 2 to Figure 3 , this embodiment is different from the first embodiment in that the flow channel S1 extends from the introduction flow channel R1 to the discharge flow channel N1 to form a one-way channel, and the two ends of the one-way channel are the introduction end S1-1 and the outlet end respectively. End S1-2, the introduction end S1-1 of the flow channel S1 is connected with the introduction flow channel R1, and the outlet end S1-2 of the flow channel S1 is connected with the discharge flow channel N1;

[0060] The flow channel S2 extends from the introduction flow channel R2 to the discharge flow channel N2 to form a one-way channel. The two ends of the one-way channel are the inlet end S2-1 and the outlet end S2-2 respectively. It communicates with the introduction channel R2, and the outlet end S2-2 of the flow channel S2 communicates with the discharge channel N2; wherein, the length of the one-way channel formed by the flow channel S1 is lon...

Embodiment 3

[0063] refer to Figure 4 , this embodiment is different from the above embodiment in that: as Figure 4 As shown, the flow channel S1 and the flow channel S2 of this embodiment extend in a plane spiral shape. The working method is the same as that of the above-mentioned embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com