Gradient electrode for negative electrode of deposition type flow battery, and application thereof

A flow battery, deposition-type technology, applied in battery electrodes, fuel cells, regenerative fuel cells, etc., can solve problems such as limiting battery performance, increasing battery ohmic loss, and increasing battery ion transmission paths, reducing ohmic loss, promoting The effect of uniform deposition and shortened ion transmission path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

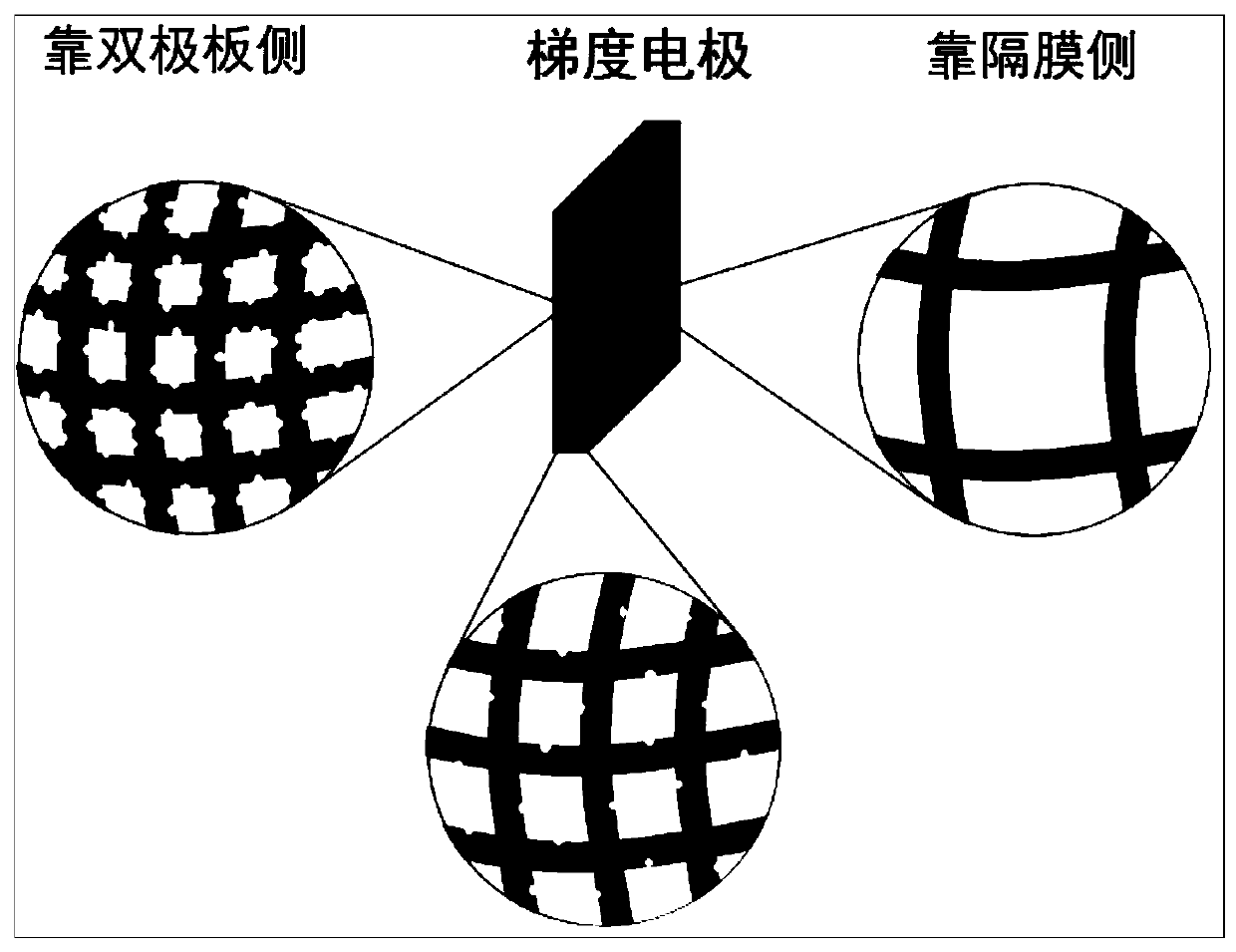

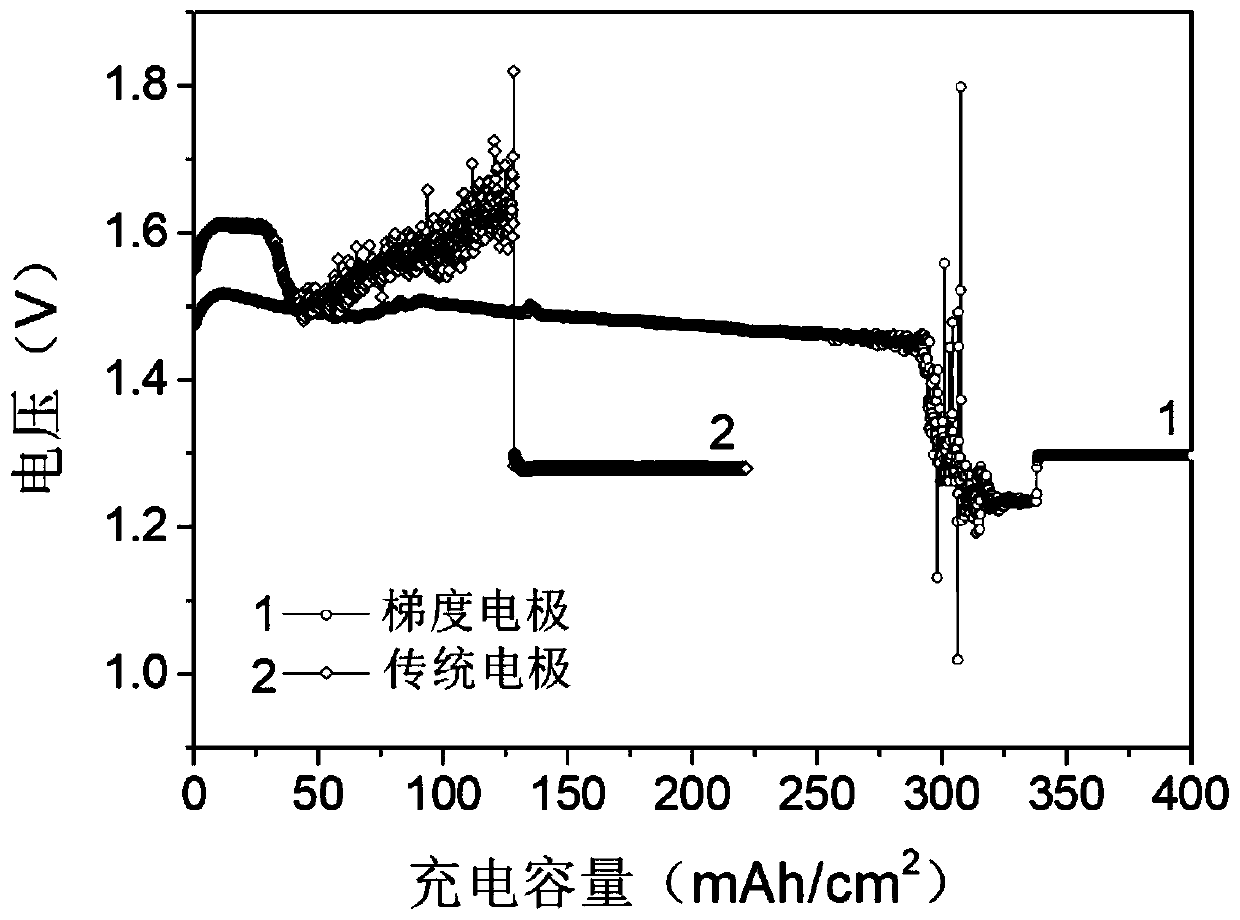

[0031] In this embodiment, a gradient electrode with a step gradient is used for the negative electrode of a deposition-type flow battery. A carbon fiber mat with a porosity of 95%, an average pore diameter of 300 μm, a ratio of oxygen-containing functional groups to the total number of atoms of 1.2%, and a thickness of 2 mm is selected for the diaphragm side, and a porosity of 86%, an average pore diameter of 80 μm, and the number of oxygen-containing functional groups are selected for the middle layer. The carbon fiber felt with a ratio of 4.5% to the total number of atoms and a thickness of 2 mm is selected from the side of the bipolar plate with a porosity of 70%, an average pore diameter of 40 μm, and a carbon fiber felt with a ratio of 9.5% of the number of oxygen-containing functional groups to the total number of atoms and a thickness of 2 mm. With a needle punching density of 200 needles / cm 2 Acupuncture machine will needle them into one piece. Under the compression ...

Embodiment 2

[0034] In this embodiment, a gradient electrode with a step gradient is used for the negative electrode of a deposition-type flow battery. Three carbon fiber mats with a porosity of 70%, an average pore diameter of 40 μm, a ratio of oxygen-containing functional groups to the total number of atoms of 1.2%, and a thickness of 2 mm were selected as initial electrodes. Laser etching is used on the side of the diaphragm to have 25 through holes with a diameter of 1mm per square centimeter, and the middle layer is laser etched to have 12 through holes with a diameter of 1mm per square centimeter. Heat treatment (air heating at 500°C for 8 hours) to increase the number of oxygen-containing functional groups to 8% of the total number of atoms, and use a needle punching density of 100 needles / cm 2 Acupuncture machine will needle them into one piece. Under the compression of the end plate, it is assembled into a zinc-bromine flow battery with a flow-through structure. After compression...

Embodiment 3

[0036] In this embodiment, a gradient electrode with a step gradient is used for the negative electrode of a deposition-type flow battery. A carbon fiber mat with a porosity of 97%, an average pore diameter of 350 μm, and a thickness of 2 mm is selected on the diaphragm side, a carbon fiber felt with a porosity of 84%, an average pore diameter of 70 μm, and a thickness of 2 mm is selected for the middle layer, and a porosity of 60% and a thickness of 2 mm are selected on the bipolar plate side. Carbon fiber felt with an average pore size of 30 μm and a thickness of 2 mm. Electrodeposit 40wt% metal bismuth on the carbon fiber felt on the side of the bipolar plate, and 15wt% metal bismuth on the carbon fiber felt on the middle layer, without treatment on the side of the diaphragm, and use a needle punching density of 200 needles / cm 2 Acupuncture machine will needle them into one piece. Under the compression of the end plate, it is assembled into a tin-iron flow battery with a f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com