Fireproof environment-friendly aluminum-plastic composite board and preparing method thereof

An aluminum-plastic composite panel, environmentally friendly technology, applied in chemical instruments and methods, layered products, metal layered products, etc., can solve problems such as fire fighting, escape, life-saving difficulties, non-compliance with environmental protection requirements, and poor flame retardant performance. To achieve the effect of improving flame retardant and fire resistance, efficient smoke suppression effect, and excellent tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

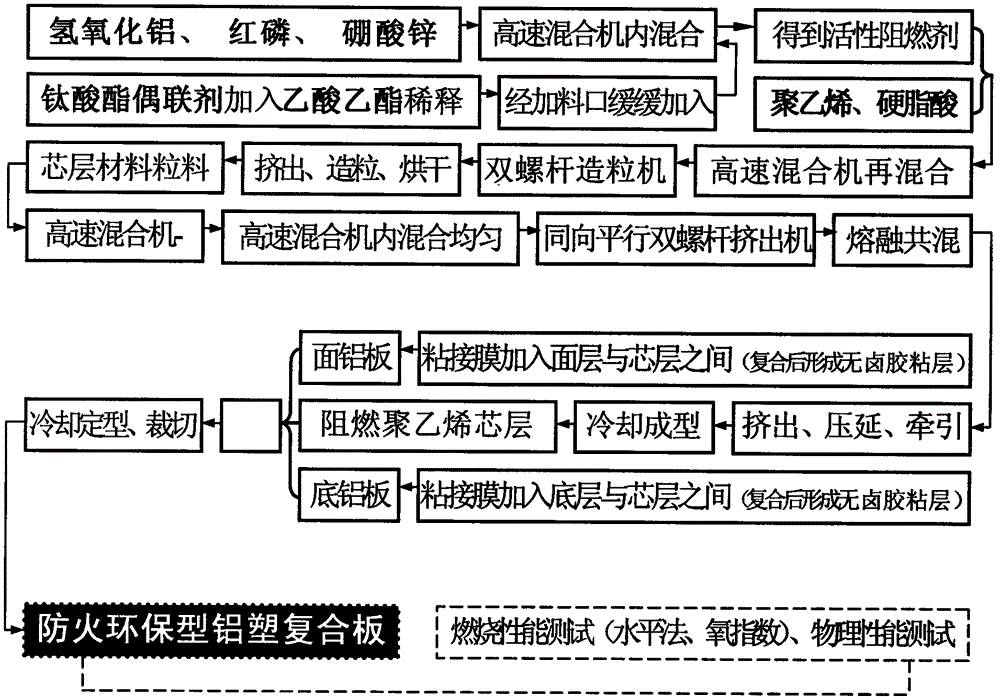

Method used

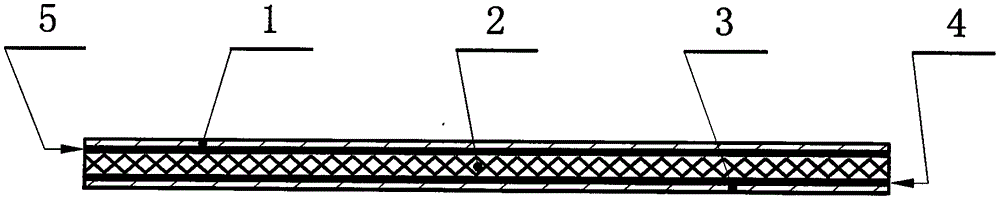

Image

Examples

Embodiment example 1

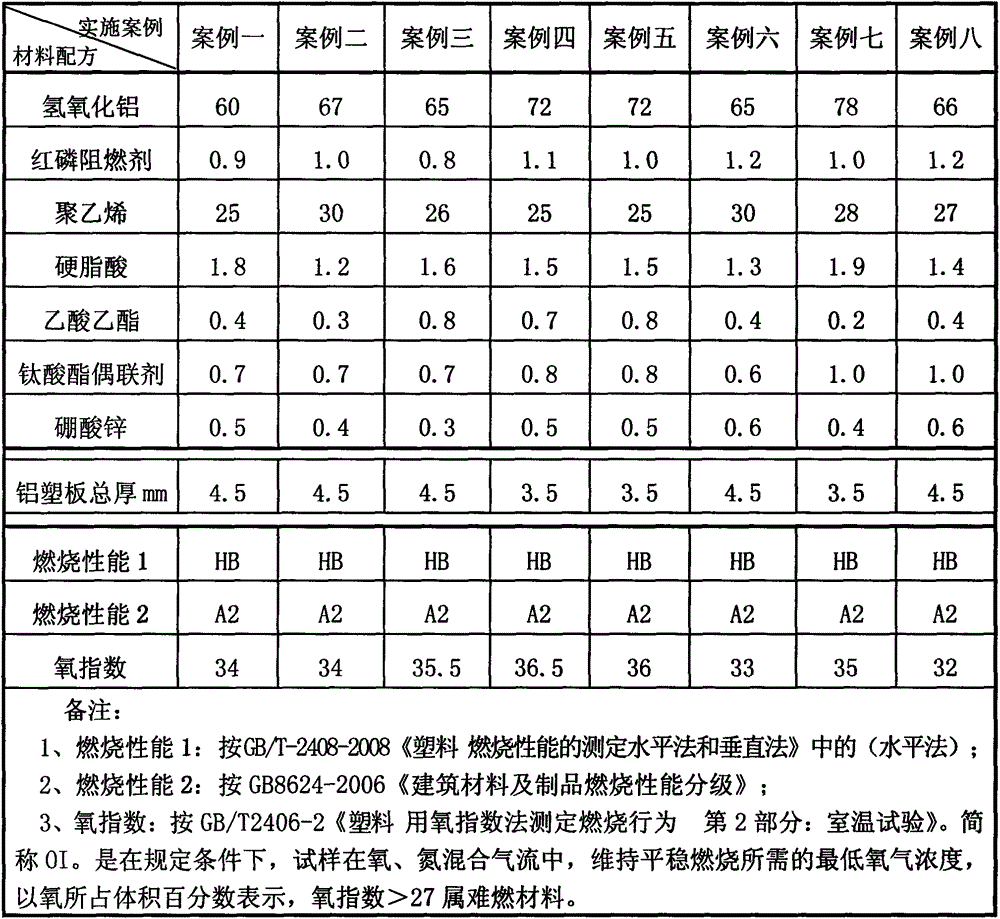

[0033] The fireproof and environment-friendly aluminum-plastic composite panel prepared in this case is used for building curtain walls with a total thickness of 4.5mm.

[0034] Select flame retardant polyethylene core layer ingredients: 60 parts of aluminum hydroxide, 0.9 parts of red phosphorus flame retardant, 25 parts of polyethylene, 1.8 parts of stearic acid, 0.4 parts of ethyl acetate, 0.7 parts of titanate coupling agent, zinc borate 0.5.

[0035] Add 60 parts of aluminum hydroxide powder, 0.9 parts of red phosphorus flame retardant, and 0.5 parts of zinc borate into a high-speed mixer and mix together; weigh 0.7 parts of titanate coupling agent and add 0.4 parts of acetic acid Dilute with ethyl ester, after 2 minutes, slowly enter the high-speed mixer from the feeding port, and then mix together for 15-25 minutes for activation treatment to form aluminum hydroxide powder, red phosphorus, zinc borate, titanate coupling agent, ethyl acetate Activated flame retardant mi...

Embodiment example 2

[0037] The following implementation cases 2 to 8, in addition to the different use occasions (for building curtain walls or for interior decoration), that is, the total thickness of the composite board is different, and the composition of the flame-retardant polyethylene core layer is different, and its preparation of flame-retardant aluminum-plastic Composite board method, exactly the same.

[0038] The fireproof and environment-friendly aluminum-plastic composite panel prepared in this case is used for building curtain walls with a total thickness of 4.5mm.

[0039]Select flame-retardant polyethylene core layer ingredients: 67 parts of aluminum hydroxide, 1.0 parts of red phosphorus flame retardant, 30 parts of polyethylene, 1.2 parts of stearic acid, 0.3 parts of ethyl acetate, 0.7 parts of titanate coupling agent, boric acid Zinc 0.4.

Embodiment example 3

[0041] The fireproof and environment-friendly aluminum-plastic composite panel prepared in this case is used for building curtain walls with a total thickness of 4.5mm.

[0042] Select flame-retardant polyethylene core layer ingredients: 65 parts of aluminum hydroxide, 0.8 parts of red phosphorus flame retardant, 26 parts of polyethylene, 1.6 parts of stearic acid, 0.8 parts of ethyl acetate, 0.7 parts of titanate coupling agent, boric acid Zinc 0.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com