Preparation method for carbon-plastic fiber composite material

A fiber composite material and carbon-plastic technology, applied in the field of composite materials, can solve the problems of plastic and wood materials not being tightly bonded, affecting the mechanical properties of carbon-plastic products, and interfacial adhesion is difficult to combine, so as to improve the interface bonding force and stability Sex, high filling, high filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

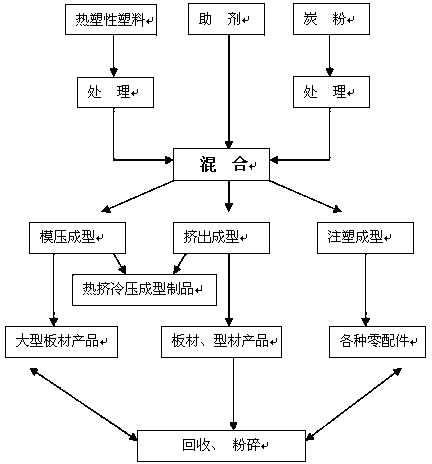

[0028] like Figure 1-5 As shown, the preparation method of the carbon-plastic fiber composite material described in the embodiment of the present invention, its steps mainly include:

[0029]⑴Select and process carbon powder and plastic: carbon powder is dried before mixing and stored in a dry place, and the plastic used as the base material can be high-density polyethylene, polyvinyl chloride, polypropylene PET, ABS and ultra-high One of the molecular weight polyethylene, according to the requirements of cost, raw material source and cost performance, recycled plastics and new plastics are used in the preparation of composite materials;

[0030] ⑵Formulation and mixing: Before processing, according to the proportion of the formula, put carbon powder, plastics and additives into the high-speed mixer for mixing, so that several raw materials and additives are evenly mixed, and make preliminary preparations for extrusion production or compression injection In order to improve ...

Embodiment 2

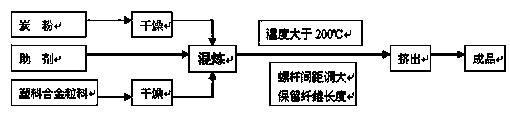

[0033] like Figure 1-5 As shown, the preparation method of the carbon-plastic fiber composite material described in the embodiment of the present invention, its steps mainly include:

[0034] ⑴Select and process carbon powder and plastic: carbon powder is dried before mixing and stored in a dry place, and the plastic used as the base material can be high-density polyethylene, polyvinyl chloride, polypropylene PET, ABS and ultra-high One of the molecular weight polyethylene, according to the requirements of cost, raw material source and cost performance, recycled plastics and new plastics are used in the preparation of composite materials;

[0035] ⑵Formulation and mixing: Before processing, according to the proportion of the formula, put carbon powder, plastics and additives into the high-speed mixer for mixing, so that several raw materials and additives are evenly mixed, and make preliminary preparations for extrusion production or compression injection In order to improve...

Embodiment 3

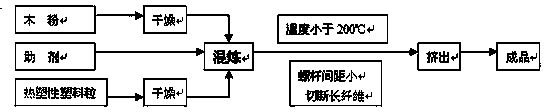

[0038] like Figure 1-5 As shown, the preparation method of the carbon-plastic fiber composite material described in the embodiment of the present invention, its steps mainly include:

[0039] ⑴Select and process carbon powder and plastic: carbon powder is dried before mixing and stored in a dry place, and the plastic used as the base material can be high-density polyethylene, polyvinyl chloride, polypropylene PET, ABS and ultra-high One of the molecular weight polyethylene, according to the requirements of cost, raw material source and cost performance, recycled plastics and new plastics are used in the preparation of composite materials;

[0040] ⑵Formulation and mixing: Before processing, according to the proportion of the formula, put carbon powder, plastics and additives into the high-speed mixer for mixing, so that several raw materials and additives are evenly mixed, and make preliminary preparations for extrusion production or compression injection In order to improve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com