Ultraviolet-curing waterborne epoxy-polyurethane-acrylate copolymer resin anticorrosive coating and preparation method thereof

An acrylate copolymer resin, water-based epoxy technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve the problem that the water resistance and corrosion resistance of coatings cannot be guaranteed, and the film-forming substances cannot achieve corrosion resistance. performance, wear resistance, poor chemical resistance, etc., to achieve the effect of good coating adhesion, overcoming poor water resistance and corrosion resistance, and high solid content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

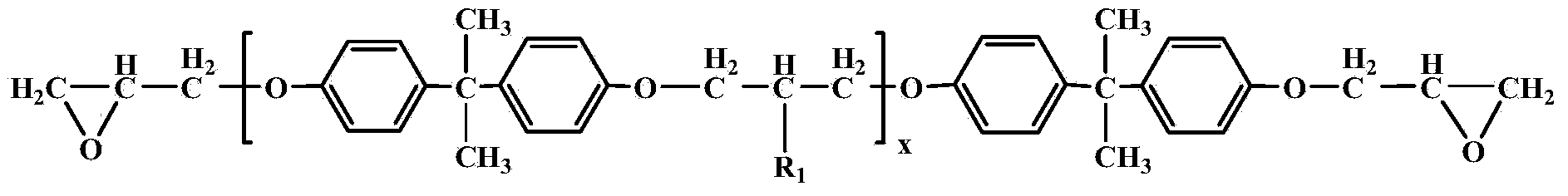

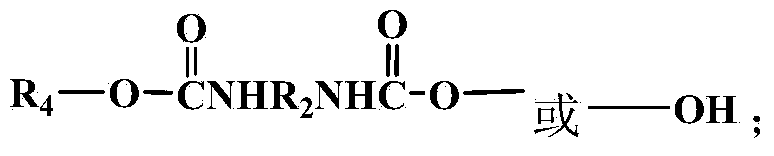

[0039](1) Synthesis of epoxy-polyurethane-acrylate copolymer resin aqueous dispersion

[0040] Add 100 parts of polyether polyol 210 (functionality 2, molecular weight 1000), 30 parts of bisphenol A epoxy resin E20 and 50 parts of isophorone diisocyanate into a four-necked flask with a stirring and reflux device , under the protection of nitrogen, react at 80°C for 3 hours, then add 10 parts of dimethylolpropionic acid to it, and carry out chain extension reaction at 80°C for 5 hours to obtain isocyanate group-terminated epoxy- Polyurethane prepolymers.

[0041] Add 30 parts of hydroxyethyl acrylate to the above prepolymer, carry out capping reaction at 70°C for 1.5 hours, then add 7 parts of triethylamine and 300 parts of distilled water, stir and emulsify quickly, and react to obtain epoxy-polyurethane-acrylate copolymer Aqueous resin dispersion.

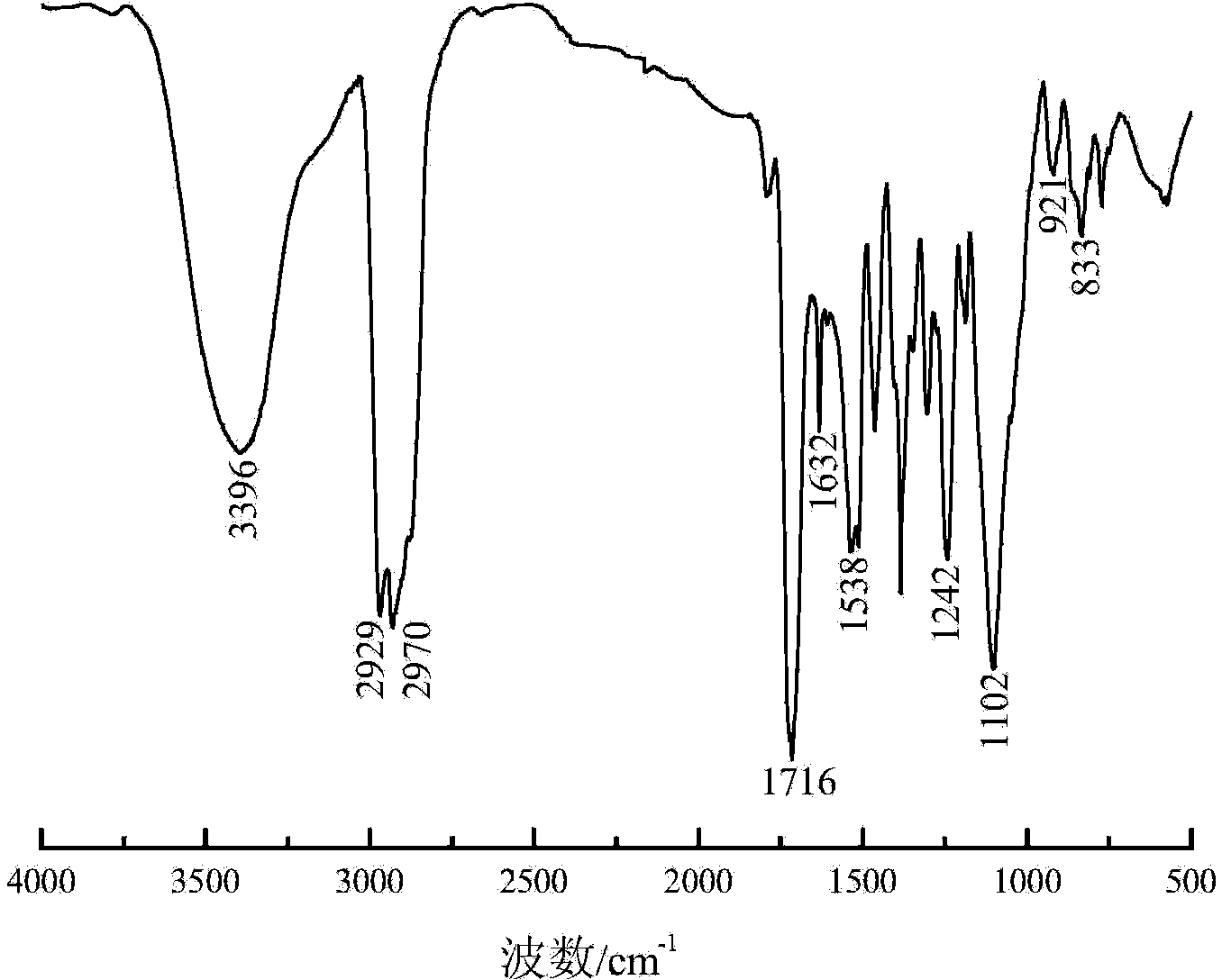

[0042] The above-mentioned epoxy-polyurethane-acrylic ester copolymer resin prepared in embodiment 1 is carried out Fourier tr...

Embodiment 2

[0051] (1) Synthesis of epoxy-polyurethane-acrylate copolymer resin aqueous dispersion

[0052] Add 100 parts of polyether polyol 210 (functionality 2, molecular weight 1000), 25 parts of bisphenol A epoxy resin E20 and 50 parts of isophorone diisocyanate into a four-necked flask with a stirring and reflux device , under the protection of nitrogen, reacted at 85°C for 3 hours, then added 12 parts of dimethylolpropionic acid to it, and carried out chain extension reaction at 75°C for 4 hours to obtain isocyanate group-terminated epoxy- Polyurethane prepolymers.

[0053] Add 20 parts of hydroxyethyl methacrylate to the above prepolymer, carry out capping reaction at 80°C for 2 hours, then add 12 parts of tripropylamine and 350 parts of distilled water, stir and emulsify quickly, and react to obtain epoxy-polyurethane-acrylate Aqueous dispersion of copolymer resin.

[0054] (2) Preparation of UV-cured waterborne epoxy-polyurethane-acrylate copolymer resin-based anticorrosion co...

Embodiment 3

[0062] (1) Synthesis of epoxy-polyurethane-acrylate copolymer resin aqueous dispersion

[0063] Add 100 parts of polyether polyol 210 (functionality 2, molecular weight 1000), 35 parts of bisphenol A epoxy resin E20 and 70 parts of isophorone diisocyanate into a four-necked flask with a stirring and reflux device , under the protection of nitrogen, reacted at 70°C for 5 hours, then added 20 parts of 2,2-dimethylolbutyric acid to it, and carried out chain extension reaction at 80°C for 2 hours to obtain isocyanate group-capped terminal epoxy-polyurethane prepolymer.

[0064] Add 35 parts of hydroxypropyl acrylate to the above prepolymer, carry out capping reaction at 75°C for 3 hours, then add 18 parts of triethanolamine and 400 parts of distilled water, stir and emulsify quickly, and react to obtain epoxy-polyurethane-acrylate copolymer resin water dispersion.

[0065] (2) Preparation of UV-cured waterborne epoxy-polyurethane-acrylate copolymer resin-based anticorrosion coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com