Ester compound and its preparation method and application

A technology of ester compounds and compounds, applied in the field of fatty acid ester compounds, can solve problems such as weak chemical bonds, very sensitive to temperature and electrolytes, and easy failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

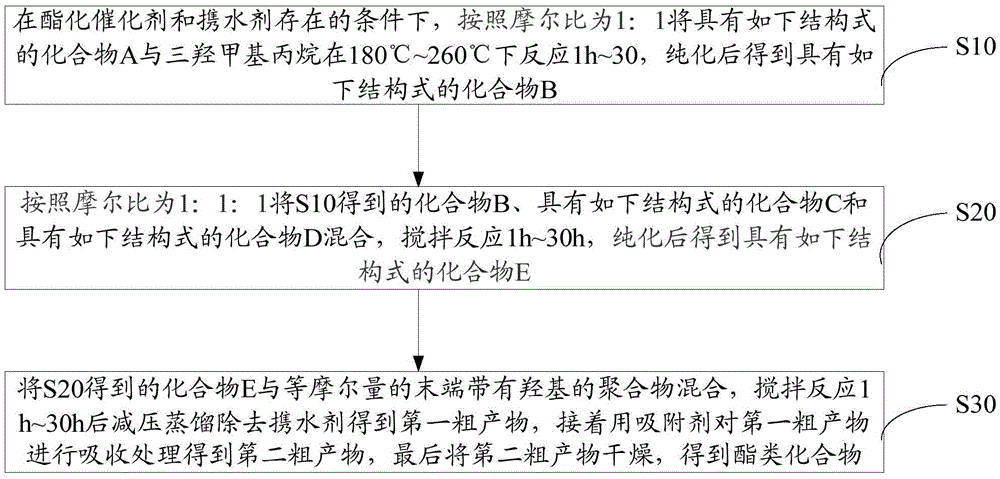

[0084] Such as figure 1 The preparation method of shown above-mentioned ester compound, comprises the steps:

[0085] S10. In the presence of an esterification catalyst and a water-carrying agent, react compound A with the following structural formula with trimethylolpropane at 180°C-260°C for 1h-30 at a molar ratio of 1:1, and obtain Compound B having the following structural formula.

[0086] Compound A: Compound B:

[0087] Among them, -R 1 It is an alkyl group having 1 to 17 carbon atoms, an alkenyl group having 2 to 17 carbon atoms, a cycloalkyl group having 2 to 17 carbon atoms, or an aryl group having 6 to 17 carbon atoms.

[0088] In one embodiment, -R 1 for -CH 3 、-C n h 2n+1 or -C n h 2n-1 , wherein n is an integer of 2-17.

[0089] In S10, the esterification catalyst is at least one of acetate, titanium compound and tin compound, and the mass ratio of the esterification catalyst to trimethylolpropane is 0.01-1:100.

[0090] The acetate is zinc acetate...

Embodiment 1

[0128] In a 1000mL three-neck flask equipped with a thermometer, an electric stirrer, a water separator, and a condenser tube, add 134.17g (1.0mol) of trimethylolpropane, 144.20g of isooctanoic acid, 1.34g of stannous oxalate and 13.41g of toluene, and heat Raise the temperature to 200°C to reflux the system. When the water content reaches the theoretical water content, add 236.18g (2.0mol) of succinic acid, continue the reaction until the water content reaches the theoretical water content, and then add polyethylene oxide terminated by a methyl group at one end (The average molecular weight is 350), react until the water content reaches the theoretical water content, cool, change to a vacuum distillation device, and distill out toluene. Thereafter, it was adsorbed with silica gel at 120° C. for 2 hours, and filtered. Next, it dried under reduced pressure (40 Pa) and 120 degreeC for 2 hours, and obtained the ester compound.

[0129] The ester compound that embodiment 1 is mad...

Embodiment 2

[0131] In a 1000mL three-neck flask equipped with a thermometer, an electric stirrer, a water separator, and a condenser tube, add 134.17g (1.0mol) of trimethylolpropane, 144.20g of isooctanoic acid, 1.34g of stannous oxalate and 13.41g of toluene, and heat Raise the temperature to 200°C to reflux the system. When the water separation reaches the theoretical water separation, add 264.22g (2.0mol) glutaric acid, continue the reaction until the water separation reaches the theoretical water separation, and then add polyethylene oxide terminated by a methyl group at one end. (The average molecular weight is 350), react until the water content reaches the theoretical water content, cool, change to a vacuum distillation device, and distill out toluene. Thereafter, it was adsorbed with silica gel at 120° C. for 2 hours, and filtered. Next, it dried under reduced pressure (40 Pa) and 120 degreeC for 2 hours, and obtained the ester compound.

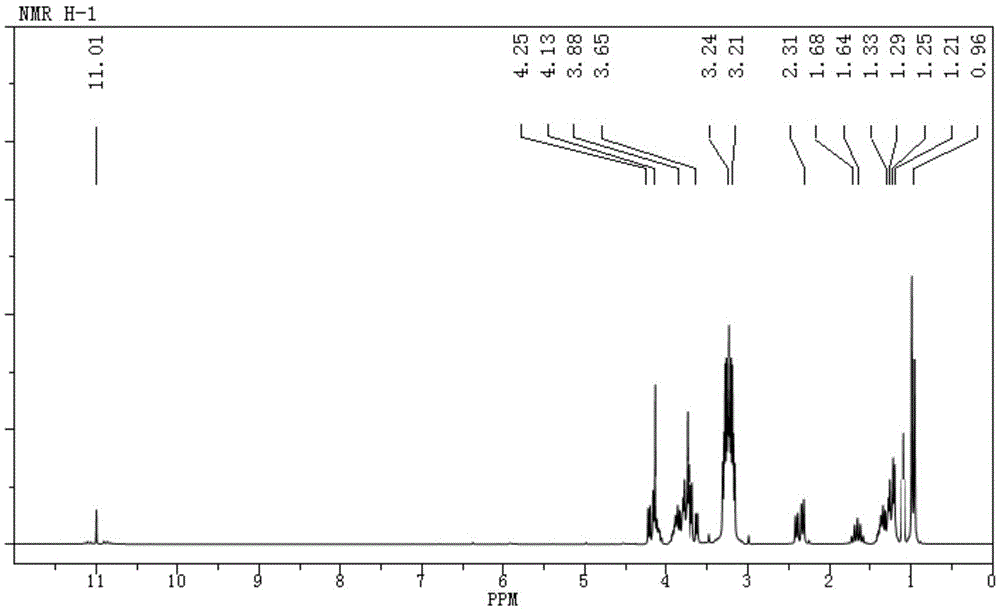

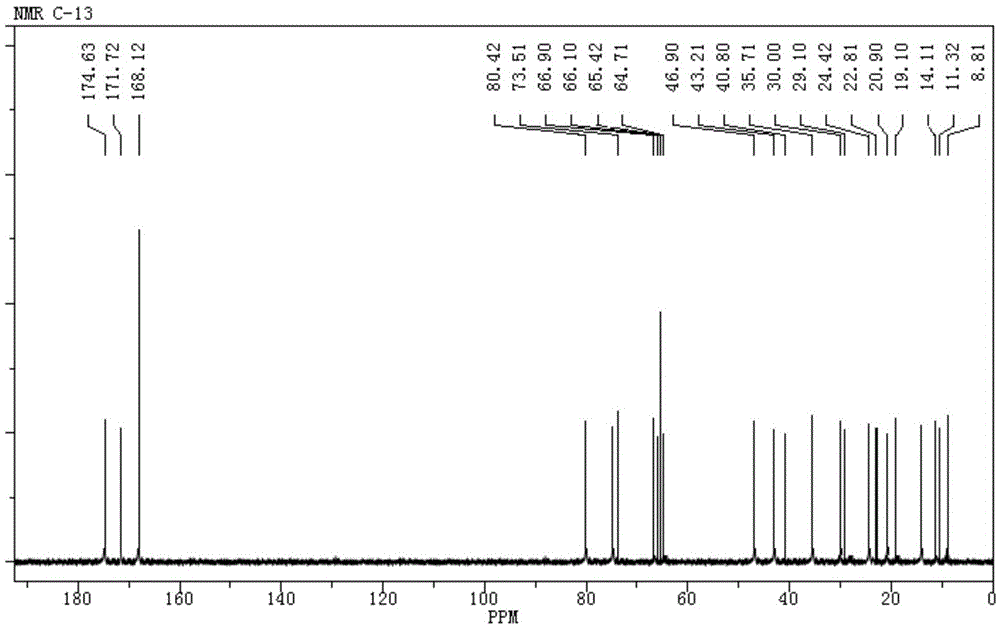

[0132] Carry out NMR test to the ester c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com