Film solar energy battery and manufacturing method thereof

A solar cell and thin film technology, applied in the field of solar cells, can solve problems such as unsatisfactory welding performance, poor welding performance, and film layer shedding, and achieve the effects of overcoming looseness and oxidation, reducing production costs, and increasing welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

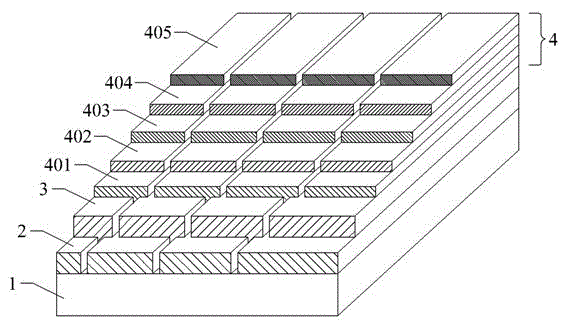

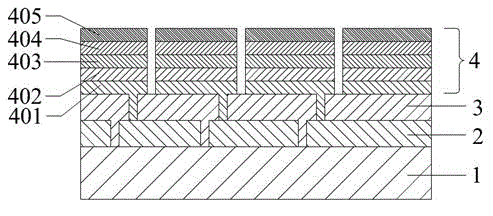

[0021] A thin-film solar cell includes a base substrate, a front electrode layer, a photoelectric conversion layer, and a back electrode layer. A reflective layer, a second reflective layer and a solder-enhancing protective layer, wherein the transparent conductive layer is aluminum-doped zinc oxide (AZO) with a thickness of 50-300nm, because AZO is relatively cheap, non-toxic and environmentally friendly;

[0022] The transition layer is chromium (Cr), with a thickness of 5-50nm, because the atomic radius of Cr is between AZO and Ag, which increases the adhesion of AZO and Ag;

[0023] The first reflective layer is silver (Ag), with a thickness of 50-150nm, because Ag has high reflective and conductive properties;

[0024] The second reflective layer is aluminum (Al) with a thickness of 50-300nm, because Al is highly reflective and cheap;

[0025] The welding protection layer is nickel-copper (NiCu) or nickel-vanadium alloy, with a thickness of 40-200nm, and has good welding...

Embodiment 2

[0027] A method for preparing a thin-film solar cell mainly includes: sequentially depositing a front electrode layer, a photoelectric conversion layer, and a back electrode layer on a base substrate, and sequentially depositing a transparent conductive layer, a transition layer, a first reflection layer, and a second electrode layer on the back electrode layer. The second reflective layer and the solder-increasing protective layer are heated before depositing the transparent conductive layer, and the heating temperature is 100-200° C.; and cooled at room temperature after depositing the solder-increasing protective layer.

[0028] The deposition method of each film layer of the back electrode layer is the DC magnetron sputtering vacuum coating method, that is, the deposition of the target is controlled by a DC power supply on a horizontal coating continuous production line, the working gas is argon, and the background pressure is 2 ~6×10 -6 Torr, the working pressure is 1×10 ...

Embodiment 3

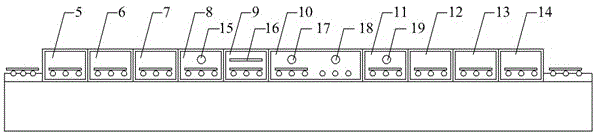

[0037] A kind of manufacturing equipment of the back electrode of thin-film solar cell, it is horizontal PVD continuous vacuum coating equipment, comprises heating room, coating room I, coating room II, coating room III, coating room IV, cooling room, coating room I is deposition transparent For the conductive layer, the coating chamber II is for depositing the transition layer, the coating chamber III is for depositing the first reflective layer and the second reflective layer, and the coating chamber IV is for depositing the solder-increasing protective layer.

[0038] Due to the complex structure and high price of the rotating target, but the high utilization rate of the target material; the simplicity of the planar target and the low price, but the low utilization rate of the target material, therefore, considering the cost performance of the target material and the rotating target, the following technical solutions are adopted:

[0039] Among them, the target material of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com