A spinning process suitable for spinning machine with external winding device

A technology of winding device and spinning process, which is applied in the field of spinning process of new spinning machine, can solve the problems of reducing product quality, increasing energy consumption, reducing efficiency, etc., and achieves the control of drying temperature and time, easy maintenance and The effect of worker operation and low power of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

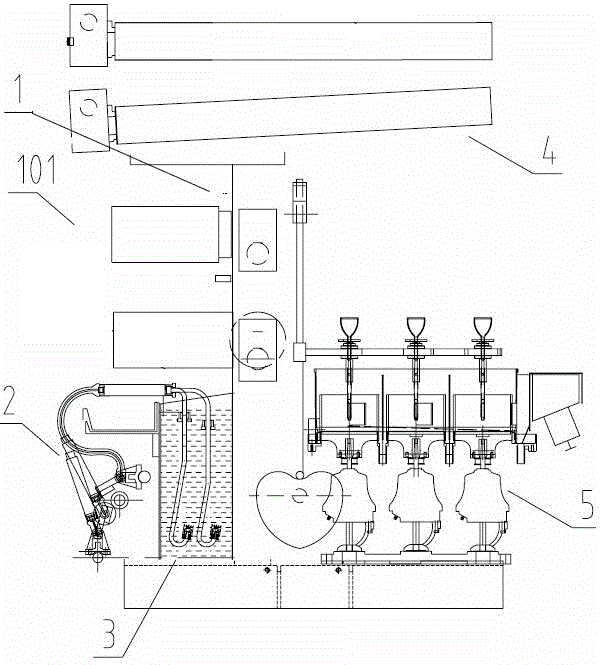

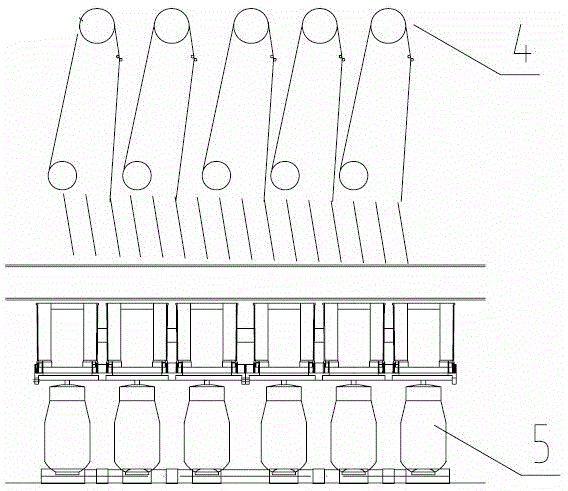

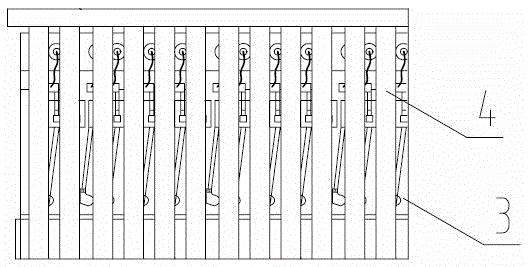

[0107] A spinning process suitable for a new type of spinning machine with an external winding device. The process includes viscose metering and glue supply, pre-spinning filtration, filament forming, spinning and winding. In the winding process, The filaments are formed into wet cake-packed filaments, wet package filaments and wet skeined filaments which can be directly used for twisting through the winding device, and the filaments are heated and dried before winding;

[0108] The moisture content of the cake-packed silk in the wet state, the packaged silk in the wet state or the skeined silk in the wet state is 50%;

[0109] The rotating speed of the centrifuge cylinder that is shaped as wet cake-packed silk is 7200r / min;

[0110] The rotating speed of the twisted motor that is shaped as wet twisted wire is 800r / min;

[0111] The packaged yarn shaped into a wet state adopts active winding and passive winding methods, wherein:

[0112] The speed of the transverse motor in ...

Embodiment 2

[0121] A spinning process suitable for a new type of spinning machine with an external winding device. Its process includes viscose metering and glue supply, pre-spinning filtration, filament forming, spinning and winding. In the winding process, the silk The strips are formed by a winding device into wet cake-packed yarns and wet-twisted twisted yarns that can be directly used for twisting, and the strips are heated and dried before winding;

[0122] The moisture content of the cake-packed silk in the wet state or the twisted-packed silk in the wet state is 40%;

[0123] The rotating speed of the centrifuge cylinder of the cake-packed silk that is shaped as wet state is 8400r / min;

[0124] The rotational speed of the skeined motor that is formed into the skeined wire in a wet state is 1000r / min.

[0125] In the glue metering and glue supply process, the gauge pressure of the glue pipe is 0.3MPa;

[0126] In the pre-spinning filtration process, viscose maturity NH 4 The Cl ...

Embodiment 3

[0132] A spinning process suitable for a new type of spinning machine with an external winding device. Its process includes viscose metering and glue supply, pre-spinning filtration, filament forming, spinning and winding. In the winding process, the silk The strips are formed by a winding device into wet cake-packed yarns and wet packaged yarns that can be directly used for twisting, and the strips are heated and dried before winding;

[0133] The moisture content of the cake-packed silk in the wet state or the packaged silk in the wet state is 80%;

[0134] The rotating speed of the centrifuge cylinder that is shaped as wet cake-packed silk is 7500r / min;

[0135] The packaged yarn formed into a wet state adopts an active winding method, wherein:

[0136] In the active winding, the rotation speed of the transverse motor is 800r / min, and the rotation speed of the rotary motor is 1000r / min.

[0137] In the glue metering and glue supply process, the gauge pressure of the glue ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coefficient of variation of linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com